We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Tools for measuring. Tools for Accuracy.

A few quality measuring tools set the quality standards for all the tools in your shop. I’ve been using these 6″ and 12″ Starrett combination squares for decades. All my measuring tools are tested against them.

Precision Instruments for Woodworkers is a 4-part series.

I’ve been working as a furniture maker for quite a while, now. Along the way, you refine your processes, develop techniques and create a lot of habits over time. Certainly, an important part of working professionally is to work efficiently —you learn very quickly that time is a fixed asset. You also learn that you have to work accurately. There are good reasons for this. Precision is not just about pride in your work, it brings serious benefits. If your measurements aren’t dead on, somewhere down the road, you can bet that it will come back to bite you with a serious mistake. Don’t ask me how I know this.

Working accurately starts by committing to use accurate measuring tools. After a few early hobbyist mistakes caused by old rulers and measuring tapes that didn’t agree, I started seeking out accurate measuring tools and have never looked back. Like every woodworker, I rely on the tools in my shop, but none more so than my measuring tools. In this short series, I’ll cover how I go about selecting and qualifying my measuring tools, the choices I’ve made and some suggestions to consider for your shop. Whether you work in hand tools, hybrid tools or use digital tools this information applies to everyone.

First, a caveat: I’m not a metrological engineer nor do I play one on television. There are better educated and experienced opinions on this topic out there so, if inclined, dive deeper if you wish. However, I am a picky woodworker. Throughout my career, I’ve depended upon accuracy and repeatability and it’s my measuring tools that make it possible. And now, the even higher requirements that come with digital woodworking have driven me to be even more methodical about precision. My approaches for selecting and validating instruments should at least get you off to a good start.

We’ll cover this topic in four parts. Tools for standardization, tools for measuring and tools for high precision. I’ll wind up with a post and video of suggested sets of tools for different kinds of woodworking. Down the road, I may add a post on measuring methods and setting up fixed tools.

Your best instruments are your standards

Every woodworker uses tapes and rules. So much so, that we often take them for granted. We shouldn’t. If you’re not using accurate measuring tools, or have been lucky so far, that’s when big problems start to happen. Now, luck might work in some woodworker’s favor, but I don’t trust any mark, position or setup unless I know that the measurements they’re based on are made in a consistent manner using accurate instruments. Given the choice between luck and accuracy, I’ll take accuracy every time.

Getting to a high level of trust is not so simple. The first step is finding accurate tools you can rely on. Like many woodworking processes or techniques, there are different ways to go about this. Rather than do this in a grand manner and consume vast quantities of time and energy to test everything in sight, I prefer to keep the process simple and direct. So, here’s how I qualify and select my measuring instruments.

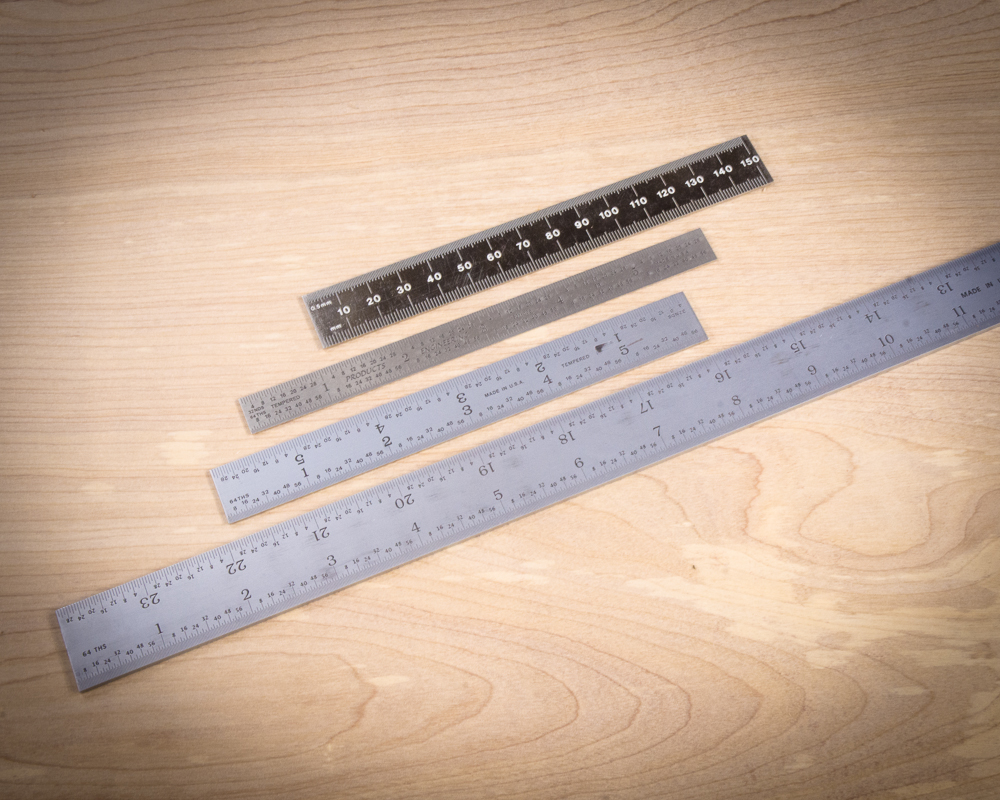

I have a number of Starrett and PEC rules in my shop. These are the ones I use most often. A metric model in black, so it’s not confused with imperial rules, a narrow 6″ stainless PEC model that lives in my apron pocket and thick 6″ and 24″ PEC rules are nearby for most precision measuring tasks. I also have 12″, 18″, 36″ and 48″ Starrett or PEC rules.

Rules and squares as reference tools

When it comes to measuring tools, I take the reference approach. I start with a set of high accuracy squares and rules and use them to verify all my other measuring tools and for tool setup. When I began woodworking as a hobby, I did what a lot of woodworkers do: I turned to machinist tools with a solid reputation. I started with a few, key Starrett tools; 12” and 6” combination squares. The 12” is over $100 and the 6” is around $70. Yes, they’re a little pricey but whether you’re a professional or amateur, I’m here to tell you that they’re worth every penny. Since I’ve used them for over 20 years, they’ve also proven to be an excellent investment. No, those cheap ones you can buy at your neighborhood home center are not the same. That small Starrett square has been living in my shop apron pocket since 1997. The larger one lives on my workbench. I depend on these tools all day, every day. That makes it easy to recommend them.

If you’re unfamiliar with the brand, Starrett has a well-earned reputation for accurate, well-made measuring instruments. A lot of engineers and machinist rely on this company’s rules and squares. There are a few other alternatives that equal or come very close to Starrett’s quality for less cost. I think it’s worth paying extra for a known result, but if cost is critical, check into Product Engineering Corporation (PEC) rules and combination squares. Besides tools branded under their own name, they make most of the rules and squares for many well-known names throughout the woodworking world. On an even lower budget? Here’s a trick: look for blems online from a trusted source. If a rule has an imperfect finish, but no technical flaws, it’s still an accurate tool.

When “square” is just not square enough. My Starrett miter squares are quite nice and accurate to two digits. Sounds great until you put up them put up against these Czech made Kinex Squares. They are tested and certified square to .003″ for the standing square and .0007″ of a degree accurate for the flat square. That’s 18 microns! Why do I have them? Besides critical CNC and machine setups, I use them to check my Starretts and other squares in case they’re bumped or dropped. There’s a .0001″/ 3-micron Kinex model available I could use to check these. Perhaps that’s going a little too far.

Establish your standards

It’s important to qualify your measuring tools, test and establish standards in your shop. You can’t just randomly rely on various measuring tools around your shop and hope for the best. You have to test them. Mixing precise tools and imprecise tools around will drive you crazy. Every tool and setup has to agree with each other. That’s why standardizing is critical to every shop. The only way to do that is to start with a few high-quality tools, use them as your standards and test your other tools against them.

It takes a great ruler to test another ruler. In testing this tape for this shot, I found it was starting to stretch when compared to this 12″ Starrett ruler. This measuring tape will be retired to service outside the shop.

Every once in a while you get lucky. This 20-year-old inexpensive Stanely square is actually pretty good when tested against a super accurate Kinex square and backlight. This square’s job is for marking boards for rough cuts

For measuring — with a few new additions I’ll get into later, I use my Starrett squares and rulers as standard setters. Makes sense. Using my highest quality and trusted tools, I qualify and regularly test every measuring tool I that I use in the shop. Testing is particularly important for measuring tapes, squares, straight edges, and rulers as these tools take abuse in day-to-day use and can become less accurate over time. Having a standard makes the process easy. You just need a few high-quality instruments, a process and to develop the habit of testing regularly.

In part two, I’ll explain my process for qualifying tape measures. Some people say I’m a little obsessive about these things. I don’t understand why they would think that way…

Additional Resources

- All posts on Precision Instruments, click here

- Digital Woodworking on Instagram

- Personal Work on Instagram

- Digital Woodworking YouTube Channel

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

“The penalty for inaccuracy is more work.”