We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Many of us have experienced the phenomenon of F-Style bar clamp slippage. It can happen to quality clamps that had been put through extensive use, but it is more common with inexpensive clamps, where the manufacturers tried to cut on production or material costs. The problem is that the moving jaw can’t anchor itself to the bar because the bar is too smooth.

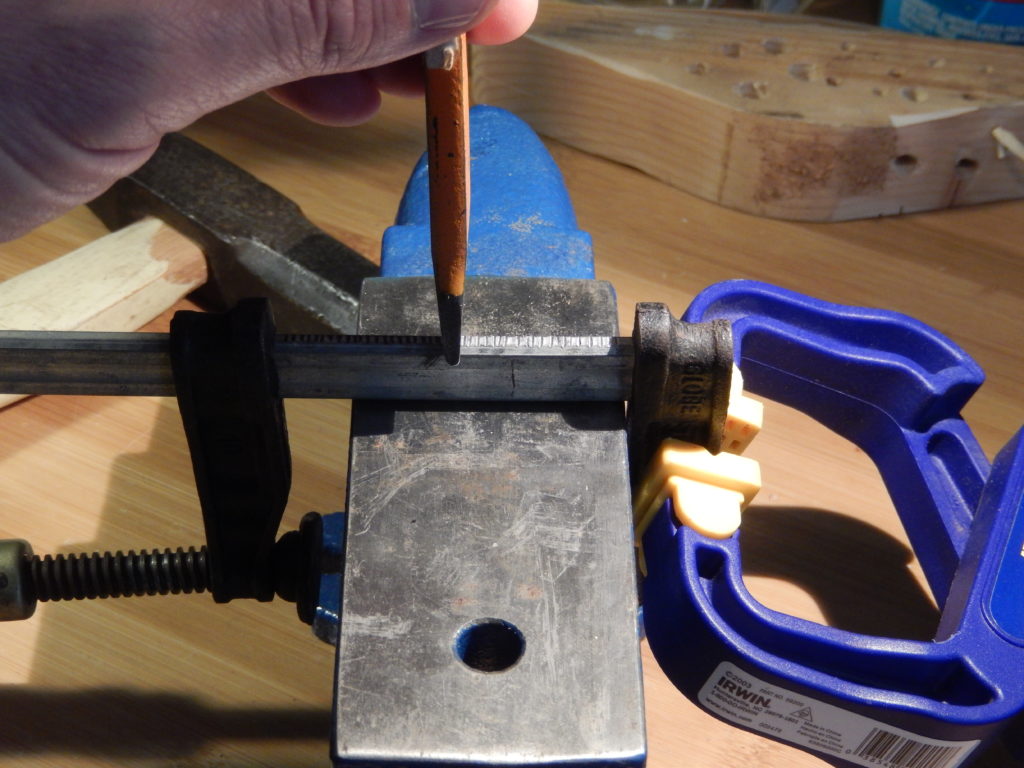

The first thing you need to do is to clean the bar from any oil residue using denatured alcohol etc. If this doesn’t solve the problem, you should corrugate the edges of the bar. The way I chose to do this was with a cold chisel and an anvil. Your biggest challenge here is to stabilize the clamp on the anvil. You can use an auxiliary clamp, magnets, or both.

Pacing the indentation is up to you. You can mark them with a rule and a sharpie pen, or you can trust your senses and let the muscle memory kick in after some practice (which I promise you it will).

With a little effort, you will be able to rehabilitate many of your challenging clamps. So the next time you see a crippled clamp in a garage sale, which in the past, you would have probably dismissed, you would now consider giving it a new home and a productive future.

With a little effort, you will be able to rehabilitate many of your challenging clamps. So the next time you see a crippled clamp in a garage sale, which in the past, you would have probably dismissed, you would now consider giving it a new home and a productive future.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.