We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Open throat planes and spokeshaves, like a scrub plane, are designed for the quick removal of thick shavings. Unfortunately, no meal comes free and the price for this quick work is an undulated and often distorted surface. You see, If the throat of the plane is large, it will leave behind a trail of course and often torn fibers.

Open throat planes and spokeshaves, like a scrub plane, are designed for the quick removal of thick shavings. Unfortunately, no meal comes free and the price for this quick work is an undulated and often distorted surface. You see, If the throat of the plane is large, it will leave behind a trail of course and often torn fibers.

In order to produce a smoother surface, one needs to make sure that their plane’s throat is closed as much as possible – enter planes with adjustable mouths or planes whose blade assembly (the frog) can be moved backward or forward to open or close the throat.

Cheap block planes, scrub planes, plus many bench planes and spokeshaves of average quality may not possess any option for either moving the blade forward or for closing the throat via a throat plate.

When I recently found a low quality plane with exceptionally open throat that practically render it useless, I decided to find an effective way to close it.

Incredibly open throat render this plane almost unless.

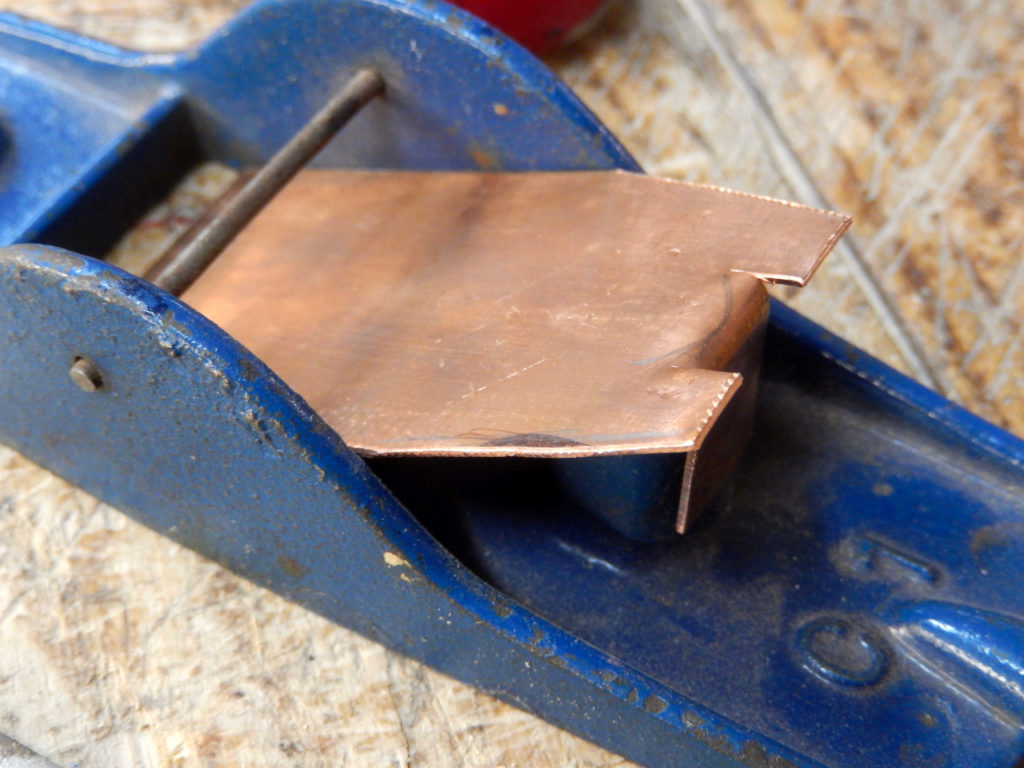

My idea was to use a copper shim between the blade and the ramp upon it rests. With a 1/32″ shim I was capable of advancing the blade forward to about 5/64”, which was sufficient, although a thicker shim would have been even more efficient.

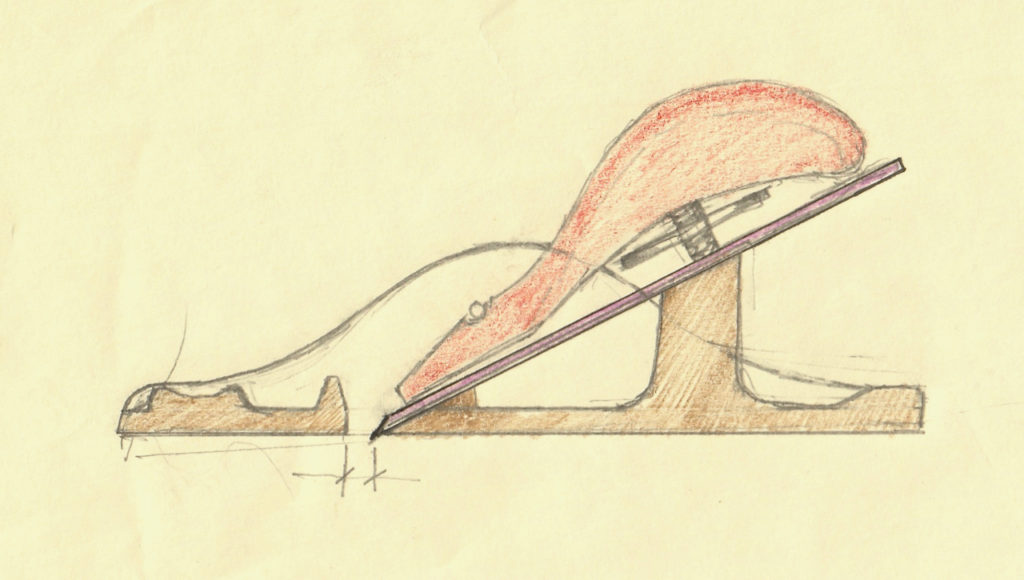

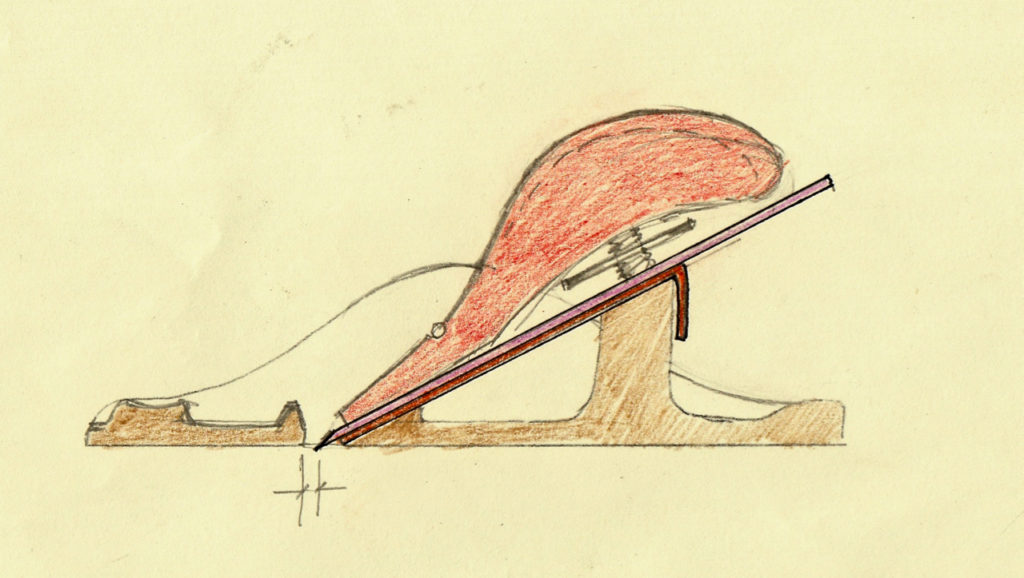

There is some trigonometry involved in the process of figuring out how much forward movement is achieved per shim thickness. I will spare you the math, but do check the drawings I made: before the shim and after installing it, as I hope they will make this point clear enough.

Before installing the shim.

After the shim was installed.

Shims have been known as effective for closing planes and spokeshaves throat in the past – Veritas includes thin plastic shims for installment inside their spokeshaves. One of the main concerns with shims is how to make sure that they will not slide up or down when the blade is adjusted. In our case, the copper shim that I built is partially anchored on the ramp, (the fixed frog), via a tab that I folded down.

If you decide to build a shim for your plane you should assess what will be the best way to affix it the frog. In most planes, a simple hole in the shim will allow the frog’s stem screw to prevent the shim from sliding as you adjust the blade; in other cases, tabs will do the trick. Copper or brass for shim making can be bought online, in hardware stores or in hobby stores.

To accommodate the shim I had to file the stern of the lever cap.

One of the advantages of shims is that they are easier to install and pulled out than advancing the frog. If your plane or spokeshave accommodates a shim, it will allow you a fast and easy switch between rapid removal of shaving and the more fine-tuned approach– just pull it out when you need to hog out wood, then bring it home when you need to smooth the surface.

Before in inches.

Before in decimal inches.

Before in millimeters.

One last piece of advice. Not all planes can accommodate a shim. Some planes whose lever cap maneuverability is somewhat restricted will not allow to tuck in a shim, so try this technique first with a piece of cardboard before you spend money on copper, brass or perhaps even …. titanium.

After in inches.

After in decimal inches.

After in millimeters.

– Yoav Liberman

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

A more permanent solution is to epoxy a shim on the short raised bed behind the mouth. In the case of the LN #103 below, several thin brass shims were added to get the desired mouth opening …

https://s19.postimg.org/b6fftgnkz/LN103-3a_zpsg9fhr6hf.jpg

https://s19.postimg.org/3nwaktw83/LN103-1a_zpsuxrwlahs.jpg

Regards from Perth

Derek

http://www.inthewoodshop.com