We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

A moisture meter is a device that lets you see the future. It allows you to avoid mistakes where your furniture will – literally – fall to pieces. But convincing woodworkers to buy one is like trying to push water uphill.

A moisture meter is a device that lets you see the future. It allows you to avoid mistakes where your furniture will – literally – fall to pieces. But convincing woodworkers to buy one is like trying to push water uphill.

This weekend, Brendan Gaffney and I were each working on some chair projects and got on the topic of moisture meters. Brendan has an idea for how to make one using a DIY circuit board and off-the-shelf parts that would make the meter quite affordable. It’s a great idea and he might write about it in the future.

But here’s the other option: Buy one today. I know it’s not a sexy tool because it doesn’t cut wood and is as romantic to use as microwaving a burrito. But it will save your butt and pay for itself quickly.

Today was a perfect example of this. I’m building a chair commission for a customer using walnut legs that I rived from a local log that had been on the ground about two years. The seat of the chair is air-dried walnut I’ve had on hand for a while.

After I shaped the legs yesterday from the riven stock, I pondered whether I should turn down the tenons so I could put the legs into the seat. The leg material felt a little cool to the touch, which usually means the wood is giving off moisture and is not at equilibrium with its environment.

A quick check with the moisture meter confirmed that the legs needed to sit some more. They all were 15 to 16 percent moisture content (MC), while the seat was 8 percent MC. That is a significant difference. If I’d assembled the chair’s undercarriage, there’s a good chance the legs would shrink and fall out of the seat.

And I would have a grumpy customer.

Buying One

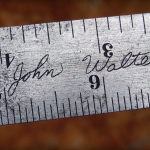

I prefer pinless meters because they don’t marr the stock, but really any moisture meter is better than no moisture meter. I haven’t, however, used all the brands on the market. About a decade ago, David Thiel and I tested a bunch of brands and didn’t find any significant difference among the meters’ accuracy. But more expensive ones (such as the one shown in the photos) were more durable and easier to set up.

— Christopher Schwarz

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Seriously in our enlightened age of advanced smart phones we should be able to get a moisture reading app by now !

I bought a moisture meter just a week ago after working wood for 40 years. I checked and nothing was 8% including 150 year old antiques. Everything in the house and most of the shop was 15%. What gives here and what do I do to get 8% raw wood or should I even worry about it?

Rick

Have you ever tried using a multimeter and the instructions from the US Forestry department they distributed in the 80’s? I know it’s a good enough reading for go/no go when it comes to burning but not sure it’s accurate enough for furniture making applications. I’m pretty sure most people that own enough tools to build furniture own a multimeter.

I use a Delmhurst (sp?) for work, and while I cannot quote a source, the general consensus is that probes are more accurate than surface-read models. The key is that the probes must be inserted deeply (a good >1/2″) into the wood, because the core of the stick of wood will naturally be more moist than the surface, and the meter should be held very steady until the reading stabilizes.

In my experience and testing, the non-penetrating readings are so ambiguous that they can only be used like a green, yellow, red traffic light.

Hello Chris – Suppose the opposite situation was encountered – moisture content of the seat was determined to be twice that of the legs? One might think that the seat will shrink around the leg tenons in the upcoming winter and add to the overall stability of the chair. However, noting the rising grain around the moisture meter in the second picture and wondering if any “round” holes cut through the seat would dry to an oblong shape and have a negative effect on the chair’s undercarriage? What is your experience? Thanks!

James

I have the $14 Digital Mini Moisture Meter (Pittsburgh) from Harbor Freight. It seems to work for me but I have nothing to compare it to. Did you include it in your tests with David Thiel? It has pretty good reviews. It is not pinless but I suppose better then nothing. I would be interested in your opinion. I also am interested in seeing Brendan’s DYI instructions.

They really opened up an otherwise mysterious world of movement and uncertainty in wood for me. Not just for buying and drying lumber – you can figure out the natural moisture content in your shop by measuring wood that’s been in it long enough (and know when you can move forward with a given board), and start getting some actual empirical evidence and feedback why your materials are changing shape.

As for that DIY version – stay tuned! I’m not sure if the readers here have access to simple electronics tools (think Heathkits) but it wouldn’t be hard to put out the PCB board design and parts list for people to make their own. Putting my weird Master’s in Computer Music to good use.