We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

If workbenches were like automobiles, then I’d consider the tail vise to be like the heated seats in a car. They’re an option, of course, but they are by no means standard equipment, like tires.

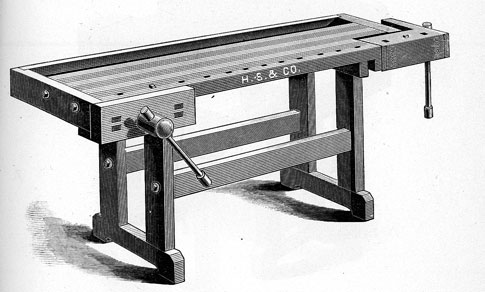

Out of economic necessity, my first three workbenches didn’t have tail vises, and so I was thrilled when I was assigned to review a full-size European workbench with all the bells and whistles, including a tail vise and massive square steel dogs.

I wasn’t impressed. The vise sagged after regular use, the steel dogs constantly slipped back into their holes (no matter how I bent them) and the vise got in the way of many operations on the right side of the workbench.

Since that first bench, I’ve had the opportunity to work on workbenches all over the world with the best tail vises – wooden, steel, tubular, you name it. I haven’t been swayed in my opinion of them. When students use them, they apply too much pressure, bowing the work off the benchtop. Or the vise sags, and the dogs have to be struck with a mallet to get the work resting on the benchtop. And dogs won’t stay above the benchtop, which requires three hands to clamp a board. Oh, and when they have to plane boards of many different lengths, they have to move the dogs all around and screw the vise in and out a lot. It’s slow.

So I do I secure boards on the bench to plane them? I don’t. About 90 percent of my handplaning is done against a planing stop on the left end of my bench. Narrow stock goes right against the planing stop. Gravity and the force of the plane keeps it in position. For wide boards, I put a batten across the workbench top – it rests against the stop and is held by a holdfast.

When I need to traverse boards, I use a doe’s foot and a planing stop. For sticking mouldings, I place a 2×4 against the planing stop and secure it with a batten, creating a simple sticking board. When using “fenced” planes, such as a plow plane, I have a number of strategies depending on the width of the work that involve a holdfast and occasionally a handscrew clamp.

Why Am I Telling You This?

I know that people who love tail vises will howl at this blog entry. And if you have a tail vise and adore it like your firstborn, then Godspeed to you. But if you are a beginner who is contemplating building that first workbench, I’d like to make the case that maybe your first workbench can be simpler, less expensive and easier to build.

Woodworkers built furniture for centuries without a tail vise. The first evidence we have of the invention of a tail vise is a drawing in a codex from 1505 in what is now Germany. The tail vise was embraced in Germany and in many Scandinavian countries. But some cultures – French, English, Chinese and Japanese – resisted the tail vise until the 19th century when it became ubiquitous on many Western-style workbenches.

If you’re interested in exploring the pros and cons of workbench vises then you probably would be interested in my book “Workbenches: From Design & Theory to Construction & Use, Revised Edition.” In that book, which might be available at your library if you don’t want to own it, I discusses all manner of vises and show how to get the most out of them.

— Christopher Schwarz

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Chris:

What??? Based on my experience with the new Lie Nielsen tail vise, could not disagree more with your tail vise comments, but lay that aside for a moment…

This is not a review of a specific tail vise or a specific bench, and why write such a review blasting all tail vises, and why do it now? Never known you to do such negative generalizations, it’s unbecoming and frankly, very disappointing.

Have a LN tail vise, installed it last year, and it’s the only vise I’d make sure was on any bench future bench build. Like my Benchcrafted leg vise, but also like twin screw vises, and even cabinet style face vises, might choose anyone of them for my next build, but could not live without my LN tail vise now that I’ve installed one.

Moreover there is no way for it to sag unless the whole bench sags, and the bench dogs are the same style as the LN wooden ones and they work fine. Never had a need for the steel versions.

Now know why Krenov called the tail vise the “main vise” and it has much more functionality than my old wagon vise,which I liked a lot.

As a woodworker, I’ve come to expect you to thoroughly review specific product, and as a journalist, that you stick with empirical data and present it in an unbiased, well structured manner……

As my favorite woodworking journalist, I’ve never felt the need to criticize your work, hope things go back to normal.

Highest Regards,

Andy

Chris, I guess this shows why people are different. You didn’t mention the maker of the bench, probably for a good reason. I do have a few comments though in support of the tail vise. Have you ever worked on a bench with a Frank Klausz style tail vise? This is a traditional European type of vise and is very resistant to sag. Certainly all metal vises are stronger and able to withstand more abuse, but Frank’s vise served him for over 50 years, his father, his grandfather . . . . . and so on. So if it weren’t a good vise, he probably would have abandoned it long ago. Second, with respect to the metal bench dogs, it sounds to me like the slots were too large for the dogs, way too large. Since this was a manufactured bench as opposed to one constructed in a shop by hand, I can see how that would happen. Properly fitted, bench dogs will take a long time to wear down hardwood before they begin to slip. But again, to each his own, Just my thoughts.

I found myself thinking along the same lines the other day as I worked a 4′ square white oak table top with a 5-1/2: ‘Perhaps having a couple of holdfasts to dodge and a few blocks of scrap thrown in to reposition every time I want to rotate the work would make things ever so much more interesting that these boringly effective bench dogs…and frozen pizza really is better than a pie from Carlo’s.’

Similar thoughts this AM…’After 13 years and tens of thousands of hours of use, shouldn’t this tail vise be sagging by now…what could I possibly have done to deserve this smoothly functioning vise which demands so little in the way of my attention?’

Really…that’s what I was thinking.

Chris – I am curious on your thoughts in using the tail vise for greenwood carved bowls. I have been following the class at LN this past week and also on Peter’s blog and it would appear they make extensive use of the tail vise for holding the bowls while carving. So, is your opinion focused mainly on a tail vise for furniture work (which I suspect) or in general?

I built my bench about 30 years ago and included a tail vice which I very rarely use. The face vice is fitted to the right side of the bench with the jaws outside the bench by about 30mm. This means that you can clamp wood in the vice and saw through it in one go without repositioning the wood. NB Vice is the British spelling.

I’m always trying to joint faces where the other side of the work is not flat. If I don’t insert shims to keep the wood from flexing, I can’t get the top flat. If the workpiece is free to move (in other words, if it’s just pressing against a doe’s foot or batten) then the workpiece shifts around as I work and the shims don’t stay in place.

Am I missing something?

You can see the same here https://m.youtube.com/watch?v=WNrof3cd1cA published in 2013 by the English Woodworker with the title “The Holdfast and the Batten – Tail Vice Alternative For Hand Tool Woodworking”. Seems like it’s a century old matter. Shannon Rogers also mentioned it in the woodtalkshow some time ago (http://www.woodtalkshow.com/episodes/wood-talk-190-we-all-have-vices/) and referred to this video. Seems like a no brainer! 😉

I was wondering how much sag a wagon vise you give — it looks like it should not cause a lot of problems (aside from the major issue of fitting the thing). I am kind of tempted by the Benchcrafted tail vise but, cost aside, it needs to be pretty damn useful to justify the trouble. I honestly think the Benchcrafted tail vise is pretty cool and I like to have stuff and not use it, rather than need to use it and not have it, but the fitting is a big job…

I agree in principle but I would be lying if I said my tail vise is useless. I over engineered mine to counter sagging and even made it adjustable per seasonal shifting. Really useful holding things in a vertical position without the chop getting in the way. And I dealt a deathblow to racking a long time ago by an adjustable shimming device that hangs underneath the bench when not in use. Made a couple of them, one for the face vise and the other for the tail. Life is good.

Now that you mention it, the only time I remember using my tail vice is as an extension. I can open it up, lay some sheetgood on it, power up my circular saw and cut a line through the opened vice.

Chris,

Could you consider an article on a related subject to the one you are discussing here – namely, the optimum placement of the holes in the bench so that the strategies you are mentioning can be fully utilized with your holdfasts, etc.? In particular, I would think the discussion would be what is the optimum placement of the holes if the goal is to minimize the number of holes.

Thanks.

In my opinion the left the right side of the bench is mostly used for storage or as Bob Easton says sharpening while working on the left side. (I am right handed.) This would interfere with the using the tail vise and so I never in stalled one. Instead I do as Chris does with doe’s foot and batons. I am also found of the Paul Sellers vise-clamp system that I modified for the Roubo leg vise. See https://paulsellers.com/2013/03/the-paul-sellers-vise-clamp-system-or/ for Paul’s discussion. I

Christopher, I built your 18th century bench using five large maple boards for the top. I placed the Benchcrafted wagon wheel tail vise in the right front corner. I love it. I use round dogs just like you recommend!.

Heated seats are an option? Peasants

Chris,

Fair enough assessment, but you do hit on the biggest tail vise issues as user error, or incorrectly built tail vises or dogs.

I’m not going to try to convert anyone to any type of vise, I just like to see them all get a fair shake. It just all depends on what sort of work you do, and the methods you use to get the work done as to what kind of vise you are going to prefer.

My opinion differs on several of your points. I’m not a one vise suits all work sort of guy, but I do like a good tail vise. I also use batons a lot, as well as holdfasts. That being said, I think you are underselling the versatility of the tail vise. I’ll get into that a little at the end.

Yes, they all sag a bit. Not a big deal. If you make the vise correctly it straightens itself out with light Clamping pressure. Even if not, the sag is barely noticeable In use with a good tail vise.

Clamping too tight is bad practice for everything, not just tail vises. Clamp a board too tightly using any vise, clamp, wedge, etc, is asking for problems in a whole bunch of areas. Simply using the vise correctly takes care of that issue.

Dogs…if you build them correctly they stay put. They should be long, square, and have a springy tongue. I routinely clamp tall or thick boards at least 1 1/2″ above the bench top without ever holding them in place. I make mine long enough to use almost 6″ over the bench top when I need to. One for every dog hole, and they recess 1/32″ below the top.

Round dogs and steel dogs are something I find problematic.

Alternative uses of the tail vise…tenon cutting, cutting dovetails, holding jigs and fixtures for pretty much everything, clamping, pulling casework and chairs apart with even pressure, squaring frames and drawers precisely, and a whole bunch else!

My apologies for both the dissent and the poor grammar, the former being my experience, the latter due to typing this out on my phone.

-Matthew

Evans Wooden Screw Co

There are many woodworker who need a prescription for: “NoViceAtAll”

Thanks for sharing.

So glad someone finally said it. I totally agree Chris!

for crafting furniture, I would have to agree that a tail vise is a luxury that you can do without. However, it comes in downright handy in disassembling chairs in need of a reglue. It can hold a rail in such a way to allow you to tap a leg off without busting a dowel. The face vise is a little harder to do this and avoiding broken dowels is a pretty good time saver!

My tail vise is covered 99.44% of the time by a “sharpening station” (laid over the top – not cinched in the vise), which is the best use of the vice.