We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

When I teach beginners, one of the most common phrases I hear is, “I cannot get this (insert tool name) to work. What’s wrong?”

They hand the tool to me and the fun begins.

Though block planes are dirt-simple handplanes, there are some important points about them that are rarely discussed in the literature. Here are the five most common problems I see with students learning how to use a block plane.

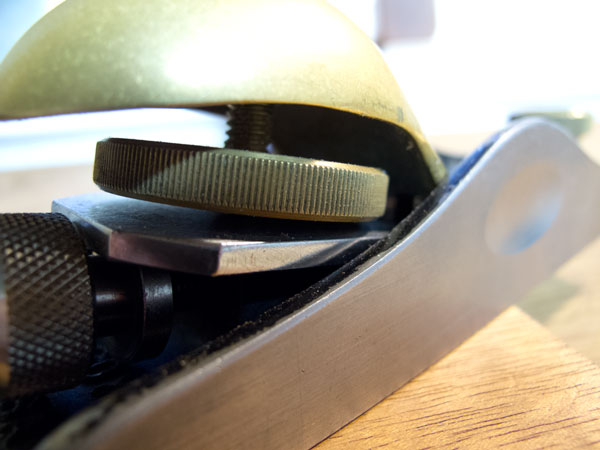

1. Too tight. Many modern planes have a spinwheel that locks the lever cap to the body of the tool. Most students have this cranked to the point where it could crush a titanium walnut. Not only does this make the tool difficult to use, it also can distort the sole. I’ve seen block planes that have a bump behind the mouth because of a too-tight spinwheel.

So how tight should it be? Looser than you think. It’s a balance: You should be able to adjust the iron with ease, and the iron should not move during normal planing operations. With my block plane, I rotate the spinwheel about three hours after feeling resistance. So lighten up, Francis.

2. Trouble at the back of the mouth, part 1. After a dozen beefy strokes, I think it’s a good idea to clear any dust in the pocket between the iron and the body of the tool. I’ve seen many planes where this area is packed with so much dust that the plane cannot cut consistently (technically, they have violated the clearance angle of the tool, but I want to talk about the clearance angle as much as I was to talk about politics, religion and infected boils).

To clear the dust, I run my fingernail along the back of the throat, staying clear of the cutting edge.

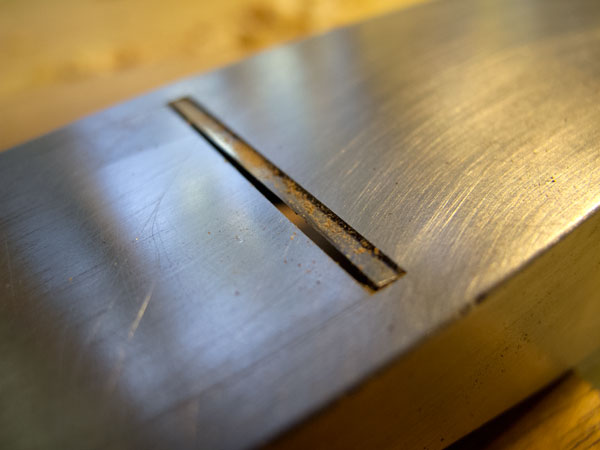

3. Trouble at the back of the mouth, part 2. The other problem with block planes occurs after five or six sharpenings. With a block plane, it is the flat back of the iron that takes most of the abuse (wonks call it the “wear bevel”). After a number of sharpenings, the wear bevel becomes pronounced and you cannot polish at the tip of the back of the tool.

The result: poor edge life and a crappy surface finish.

The solution: Sharpen your block planes using the ruler trick, which polishes the wear bevel. Problem solved.

4. A dinged sole. No matter how sharp the iron is, the wood will look like garbage if the sole has any dings. Block planes take a lot of abuse, so it’s common to see the rim of the sole deformed from hitting other tools on the bench.

A small ding on the sole can ruin an entire carcase side in a few strokes. So I regularly check the sole as I plane. Anything the looks or feels like a ding gets sanded or (in serious cases) filed away with a fine needle file.

5. Plane tracks. If you use the block plane to produce final surfaces you need to tuck the corners of the iron into the plane’s body. That means you should sharpen a curve on the iron, or file the corners round.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Hey Chris, the article was very good. As I read it I was also wondering why waiting 3 hours would make a difference. Now it makes sense. When I was very young (teens) I broke the cast cap on my boss’s plane by over tightening. I think I must have rotated the spin wheel about 36 hours after feeling resistance. Ha Ha. He didn’t laugh. Now I teach Wood Tech in high school and one of the most important steps to teaching a student the correct techniques to proper hand tool use, starts with sharpening. After my students spend a lot of time sharpening the tools at the beginning of the school year, the respect they have for the tool is immense. My first two years I did not do this because I didn’t trust them sharpening tools. They would drop chisels, and even plane nails, only to go grab a new tool that was sharp. Now they listen better to lessons and treat the tools better than their iPhones.

Chris, could you explain the “ruler trick”?

I’ve been finding that I’ve kept all my planes caps on too tight. Funny thing is, they work better a tad “loose”, as long as the iron doesn’t move. Thanks for the proof that what I discovered is really the right way to go!

I found that an over tightened spin wheel will distort the lever cap on new generation Sweetheart block planes. For me, this caused a situation where the cap iron would slip/move away from the edge of the blade when in use.

Woodworking without Chris is like a foot without a big toe. And Chris isn’t always gonna be here to be that big toe for us. I think that we owe a big round of applause to our bestest buddy and big toe… Chris Schwarz.

I’d add having the mouth too tight. We are all encourage to have a tight one, but often a block plane is used a bit heavy, and can choke.

This was my first plane, or maybe I should say my first good plane. I will certainly try tip #1. Although I don’t use a vise-grip and breaker bar to tighten, I’m probably going too tight, and will “lighten up”.

It’s ok pmac, I got tripped up on that one too. But I thought if Chris says to wait three hours, ok, he must know what he’s talking about. 🙂

Maybe it’s too early and I need my coffee, but I’m having trouble deciphering the sentence,”I rotate the spinwheel about three hours after feeling resistance.” Thanks for the tips. Glad to see that you’ve been shamed into offering real information in your blog instead of the fluff like the last couple of posts. 😉