We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

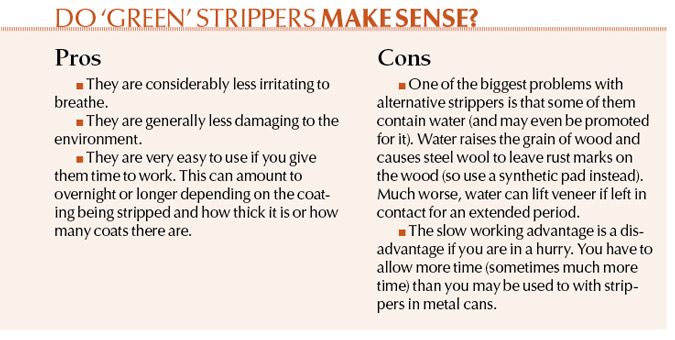

Green strippers. The failed attempt to introduce alternatives to methylene-chloride strippers in the early 1990s is having a revival as “green.” (Notice the green coloring on the labels.) The strippers pictured here all work great, but they do so considerably more slowly than traditional methylene-chloride and combined-solvent strippers. If you have the time, however, these alternative strippers are actually easier to use because they can remove many coats of paint or finish in one application.

Safer strippers are having a ‘green’ revival.

Methods for removing old paint and finish from furniture have gone through at least four distinct periods.

Before solvents became widely available, coatings were removed by scraping, often with glass used like we use scrapers, and sometimes by sanding, after sandpaper became available.

(Heat and caustics such as lye have never been a good idea for furniture because they can lift veneer and separate joints. Also, lye will turn most hardwoods black.)

The first active solvent widely used for stripping was benzene. It was cheap and fairly effective, and it was sometimes combined with other solvents to make commercial strippers.

By the early 1970s, however, benzene was shown to be carcinogenic. It was taken off the market and replaced as a stripping solvent by methylene chloride, which is more expensive but also more effective – that is, stronger and faster acting.

Other solvents were also used in combinations to make less expensive (and less effective) strippers. These include acetone, MEK, toluene, xylene and methanol. Sometimes, these solvents were combined with methylene chloride to reduce its cost. All of these solvents are flammable while methylene chloride is not.

Each of these strippers is still widely available and easily recognized by the packaging – in metal containers rather than plastic. High-percentage methylene-chloride strippers are noticeably heavier than the combined-solvent strippers and are labeled “non-flammable,” so they are easy to recognize.

In the mid-1980s, methylene chloride came under scrutiny as a possible human carcinogen. The evidence for this was weak and is still in dispute. But the doubt created, plus the flammability and toxicity of the other solvents used in strippers, was enough to create a market for an entirely new line of paint and finish removers with reduced toxicity.

It isn’t that these solvents are much less toxic; it’s that they evaporate so much more slowly (remaining wet on the wood for up to a day or two). There’s plenty of time for the air in a room to turn over several times before it reaches toxic levels.

Alternatives

The pioneers in this new category were Safest Stripper and Wood Finisher’s Pride. You may remember them from the early 1990s. Their introduction was accompanied by a great deal of advertising, focused primarily on replacing methylene chloride, which was prominently branded a carcinogen.

Safest Stripper was based on di-basic esters (DBE): dimethyl adipate, dimethyl glutarate and dimethyl succinate. These solvents are often used in so-called “safe” or “green” cleaners, including graffiti and paint-spatter removers. When used alone, DBE is often combined with water.

Wood Finisher’s Pride was based on n-methyl-pyrrolidone (NMP). This solvent is stronger (meaning it works faster) and more expensive than DBE.

The flurry of advertising created enough interest for many additional companies to enter the market with their own versions of alternative strippers, some combining NMP with DBE. It got to the point that every paint store and home center stocked several brands.

Then, fairly suddenly, this entire category of strippers almost disappeared from the shelves. What happened?

In my opinion, alternative strippers disappeared because of a major marketing mistake. Every brand exaggerated the time it took for their stripper to work. That is, they claimed much less time than it actually took for them to work.

Manufacturers chose to compete with the speed of methylene chloride, which they couldn’t legitimately do, instead of promoting ease of use. Instead of having to fight the rapid evaporation rate of the traditional strippers, you could relax, be patient, and eventually remove all coats with a single application of stripper.

The exaggerated claims got strippers packaged in plastic the reputation of “not working.” Customers complained to store clerks, and store clerks warned potential customers. Then the market dried up.

Swell and blister. Most paints and some clear finishes swell and blister, no matter which stripper you use. You can scrape them off flat surfaces or scrub them off complex surfaces using abrasive pads.

Test first. Alternative strippers work slowly, but they stay wet for days. They will remove multiple layers of paint if you give them time. This is their great advantage. You don’t have to fight the rapid evaporation as you do with traditional strippers. In this case, after 24 hours, a little more time was needed before five layers of paint came off easily.

The ‘Green’ Revolution

This situation continued until recently when “green” entered the marketing vocabulary. Terms such as “biodegradable,” “non-toxic,” “water-based,” “earth friendly,” “no harsh fumes,” “soy-based” and “citrus” took on strong marketing clout. (Soy and citrus are misleading because they don’t refer to the active ingredient, which is NMP.)

Alternative strippers fit many of these terms well, so makers reentered the market, often with newly labeled products.

Exaggerated working times and hyperbole didn’t disappear, but the bet is that consumers are now so desirous of avoiding bad-smelling solvents that they will try these strippers anyway.

Dissolve. Shellac and lacquer, the finishes used on almost all furniture made since the 1820s, usually dissolve and are easy to wipe off with rags or durable paper towels.

Release bond to wood. Some coatings, notably modern high-performance paints and finishes show no evidence that the stripper has had any effect, but, in fact, their bond to the wood has been broken so they are easy to scrape off.

Do They Work?

The question is: Do they work adequately enough to be legitimate replacements for methylene chloride and flammable-solvent combinations? The answer, in my opinion, is that they do. They just take longer on most coatings.

It’s important to note a second problem with manufacturers’ speed claims. No matter which stripper you use, whether in a metal or plastic container, different coatings react differently.

For example, shellac and lacquer dissolve fairly quickly and become a “gunk” that is easy to wipe off (though not so quickly with DBE). Varnish, oil paint and usually latex paint swell and blister. Oil-based polyurethane and two-part, high-performance (catalyzed) finishes have their bonds to the substrate broken so you can scrape them off.

If you want to avoid the irritating solvents in traditional strippers, give an alternative stripper a try. Just allow more time than the label says. Unless I’m in a hurry, I always go to one of the alternative strippers.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.