We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

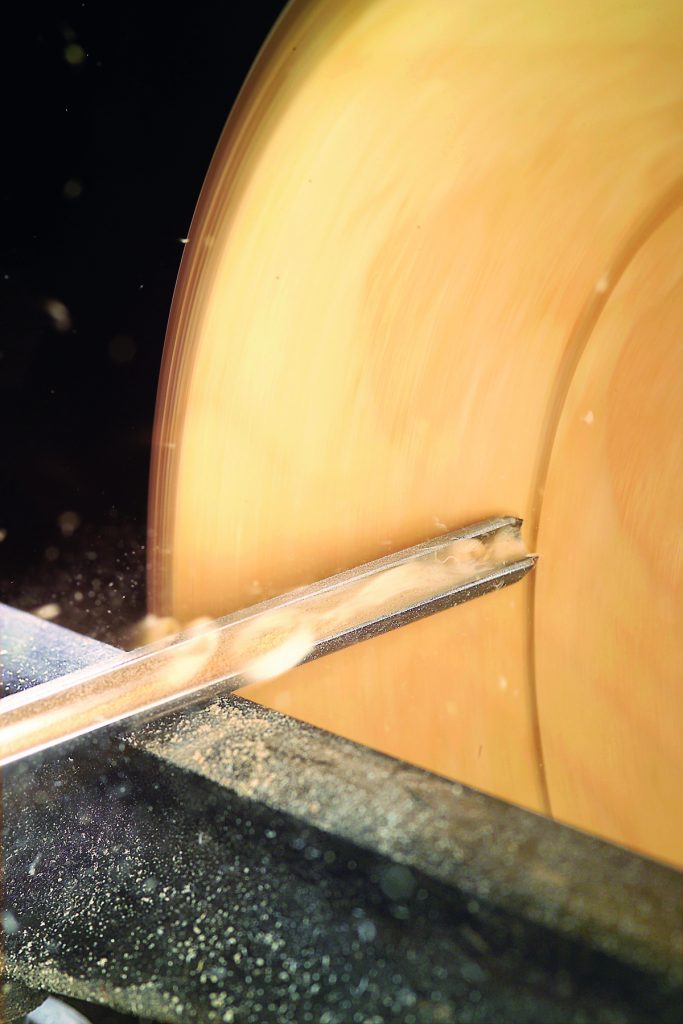

Bowl turning is a blast! Thanks to advances in lathes and tooling, lots of woodworkers have now discovered how fun it is to turn a hunk of green wood into a beautiful bowl. Start to finish, it only takes a few hours, and the wood is usually free.

Whatever the bowl’s shape, you need one basic tool: a bowl gouge. I’ve been asked countless questions about how to buy a bowl gouge during my 40 years as a professional instructor. There’s a lot of confusion about what a bowl gouge really is, how it’s sized and ground, and which type is best. Here’s what you need to know to get started.

What is a Bowl Gouge?

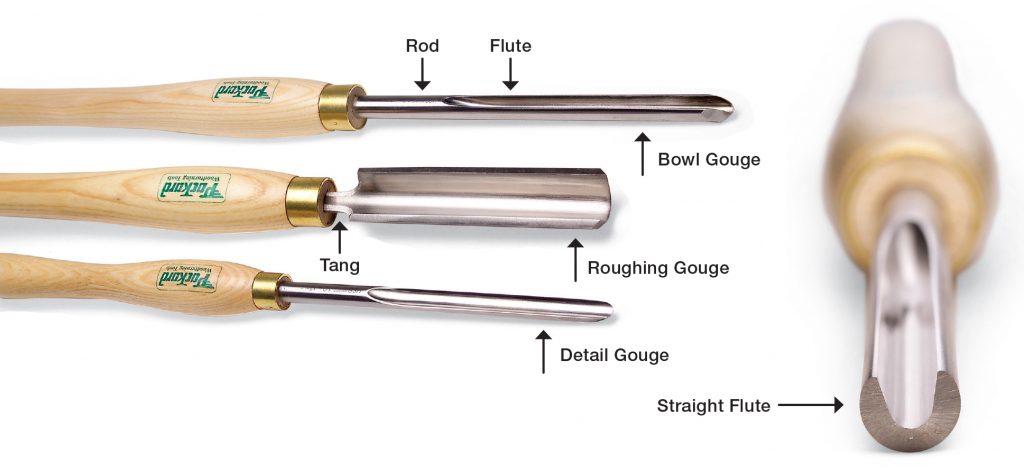

A modern bowl gouge has three parts: a rod, flute and handle. A solid round rod makes the tool very strong. The rod’s flute is generally a deeply cut oval, which improves the tool’s chip-cutting action. A bowl gouge usually has a large handle, about 16″ long, for increased leverage.

A bowl gouge is often confused with a roughing gouge. A roughing gouge is used in spindle work, such as turning a table leg, to remove a blank’s square corners or cut a cylinder or taper. It should not be used for faceplate work, such as turning a bowl. A roughing gouge has a tang, which isn’t designed to take as much downward pressure as a rod. The tang could bend or break under the larger force involved in turning a bowl.

A bowl gouge is often confused with a roughing gouge. A roughing gouge is used in spindle work, such as turning a table leg, to remove a blank’s square corners or cut a cylinder or taper. It should not be used for faceplate work, such as turning a bowl. A roughing gouge has a tang, which isn’t designed to take as much downward pressure as a rod. The tang could bend or break under the larger force involved in turning a bowl.

Bowl gouges are also often confused with detail gouges, which are also called spindle, fingernail or shallow gouges. A detail gouge has a shallower flute than a bowl gouge. A detail gouge is designed for shaping small elements, particularly in spindle work, although it is used in bowl turning for shaping rims, bases and feet.

Flute Shapes

The flute is the inner, milled portion of a bowl gouge’s rod. The flute’s shape varies among manufacturers. Its deep oval may have round or straight sides. Both types are easy to learn how to handle, so it doesn’t really matter which one you get. Individual turners have their favorites, but no single design is a runaway winner.

Bowl Gouge Sizing Systems

Manufacturers use two different, competing systems to size bowl gouges, which can be confusing. In the commonly used English system, a gouge’s size is approximately the width of its flute. In the less commonly used North American system, the gouge’s size is exactly the diameter of the rod (which I think makes a lot more sense). As a result, the same gouge is usually labeled 1/8″ smaller in the English system than in the North American system. For example, a 1/2″ gouge in the English system is the same size tool as a 5/8″ gouge in the North American system. Note which system a dealer uses before you order.

Bowl Gouge Sizes

Bowl Gouge Sizes

Bowl gouges are available in a wide range of sizes. You don’t need a whole set. If you own a standard-size lathe with a 12″ to 14″ swing, buy a 1/2″ gouge, English System (5/8″ North American). All the gouges shown here are sized by the English System.

1/2″ bowl gouge is a nicely balanced size for most bowl turning on a standard-size lathe. With this workhorse tool, you can turn 5″ to 24″ dia. Bowls.

3/8″ bowl gouge is a better choice if you own a mini-lathe. This gouge is large enough to turn a bowl as big as the machine can handle

1/4″ bowl gouge was traditionally used for finishing the inside or outside of a bowl. I prefer to make a light finishing cut with a 1/2″ gouge that has a fingernail profile.

5/8″ or 3/4″ bowl gouge is useful for making heavy, aggressive cuts on bowls larger than 14″ in diameter. Turning a monster bowl usually requires a heavy-duty, large-capacity lathe with a 2HP or larger motor.

Edge Profiles

Bowl gouges come with many different edge profiles. This shape is also called the tool’s grind, because it’s created and altered on the grinding wheel.

Each profile has its pros and cons. You don’t have to worry too much about which profile a new tool has, because you can reshape it. Whatever its profile, or price, a new tool often needs reshaping or more sharpening.

Traditional Grind

Many bowl gouges come with a traditional profile. This shape is easy to sharpen but has limitations. For some bowl shapes, it’s difficult to rub the bevel on either the inside or even the outside of the bowl.

Fingernail Grind

Fingernail Grind

I call this profile the fingernail grind. It’s more versatile than the traditional profile, so I recommend it for beginners. Few gouges come with this profile, though; usually, you must grind it yourself.

Irish Grind

Irish Grind

This swept-back profile has been called many names, including Irish, Celtic, side grind and Ellsworth. This is the most versatile profile, allowing you to rough, scrape and finish a bowl with a single tool. It is a bit more difficult to sharpen and use than other profiles.

Bowl Gouge Steel

Bowl Gouge Steel

Look for a bowl gouge made from high-speed steel (HSS) rather than high-carbon steel. A HSS gouge resists wear much longer and can’t normally be softened by overheating on the grinder. There are three general grades of HSS to choose from (see chart); all can be made equally sharp to begin with, but higher grades hold their edge longer. Most HSS gouges are made from M2 steel, which is an excellent alloy. I recommend you buy an M2 gouge first, before you become an expert sharpener, because the extra steel you’ll remove while learning how to sharpen is less expensive!

Alan has been a turner, teacher, writer and demonstrator for more than 40 years. See more at alanlacer.com

Alan has been a turner, teacher, writer and demonstrator for more than 40 years. See more at alanlacer.com

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.