We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

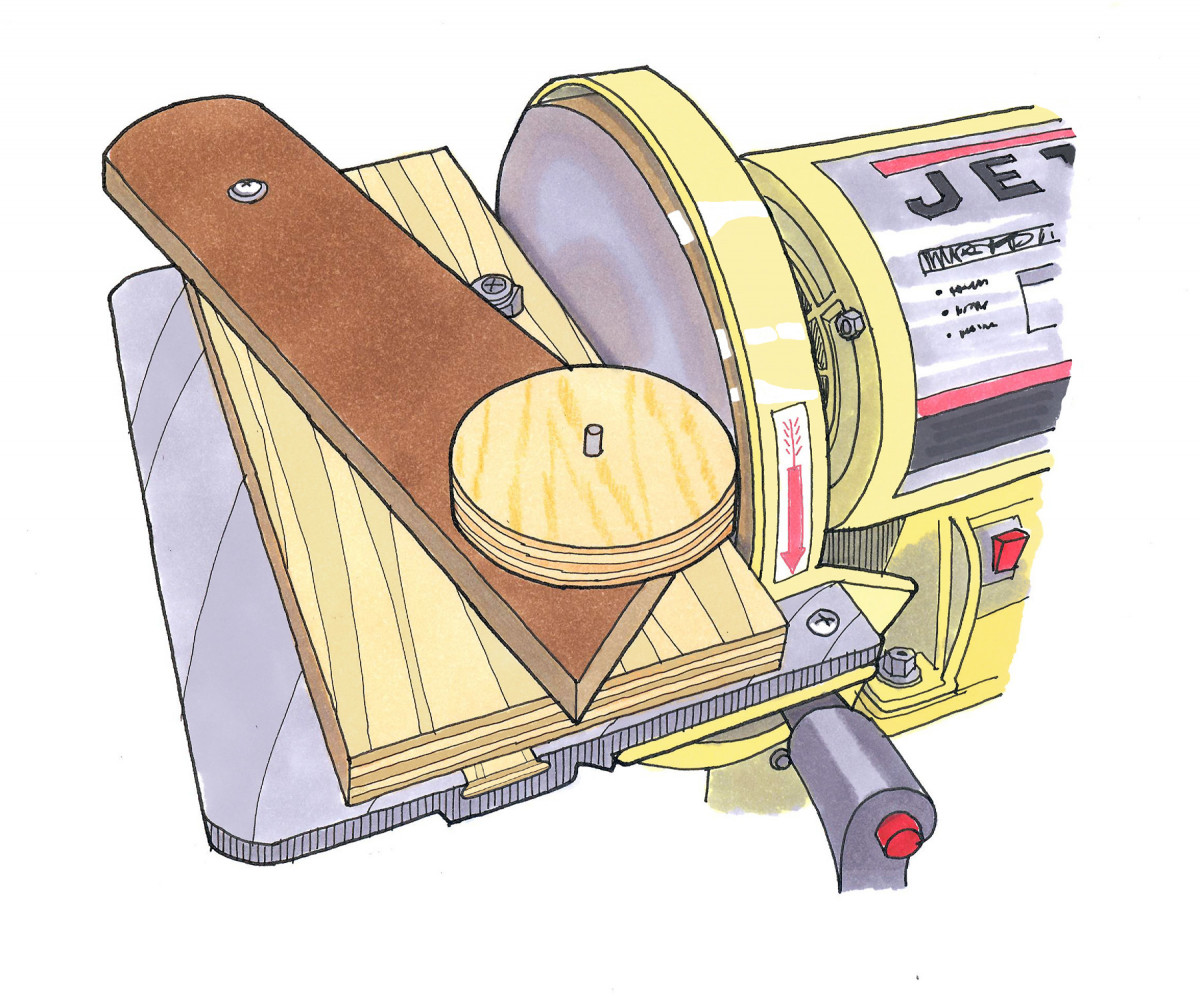

I find myself needing a lot of small circles for use on wooden toys. When I cut those disks out with a circle-cutting jig on the band saw, the edge is a little too rough, so I’ve made a fixture for the disk sander that makes quick work of sanding the wheels perfectly round and smooth.

A ledger strip on the bottom plate of the fixture fits into the sander’s miter slot to hold it in place. Atop that is a moveable arm, secured in place loosely enough so that it can freely pivot. At the working end, I cut off an 1⁄8” drill bit that fits through the holes in the center of the rough disks; it’s epoxied in place to the swing arm. In front of the arm is a stop that controls the diameter to which the disks are sanded (it’s simply screwed in place, and can be easily moved as needed).

I slip a rough disk onto the cut-off drill bit, then swing the arm into the rotating sander until the disk contacts it. The motion of the sander rotates the disk at high speed and sands it round in seconds, while the stop keeps it from getting too small. –Dan Martin

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.