We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

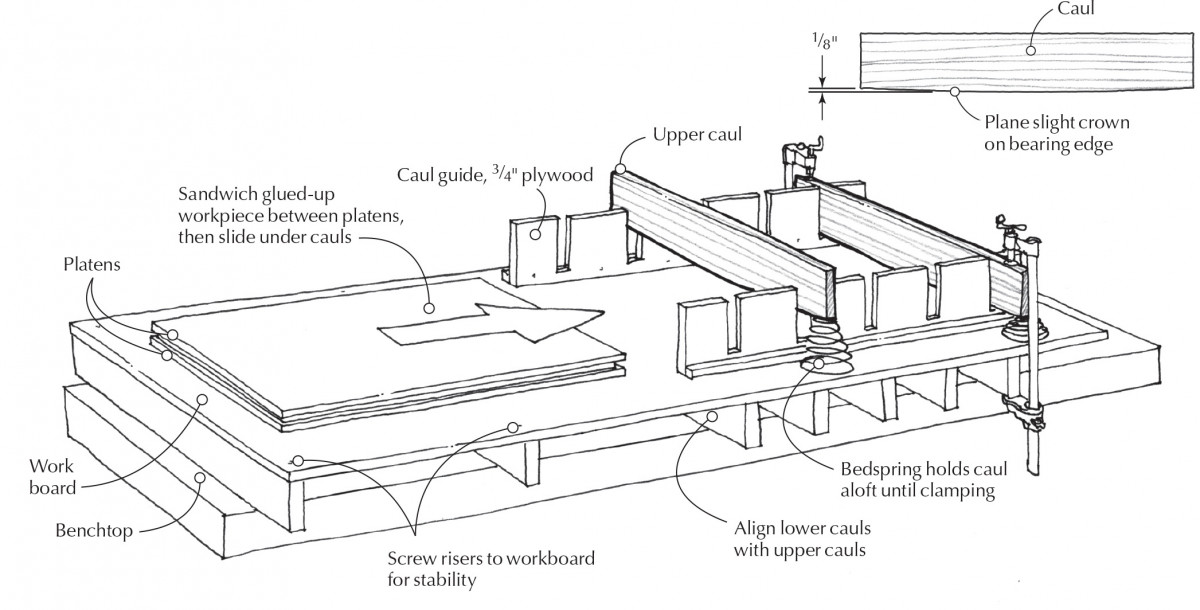

Occasionally, I like to veneer my own cabinet doors. Like many small-shop woodworkers, I do the job by covering the veneered face with a platen, then applying clamping pressure onto the work via hardwood cauls that extend across the platen. The cauls are slightly crowned on their bearing edges to better transfer clamping pressure to the center of the platen.

In the past, I had to use special slow-set glues to allow enough time to position all the cauls and clamps. Unfortunately, these glues required longer clamping time, which tied up the press and slowed down progress, especially when producing multiple panels. I decided I needed a better system, so I devised this benchtop setup that saves a lot of time and does a great job. It can also be easily broken down and stashed away when not in use.

The setup consists of a workboard panel atop a couple risers and a series of thick, wide clamping cauls that extend slightly beyond the edges of my bench. The opposing upper and lower cauls ensure consistent pressure and flat panels. At one end of the workboard, I use cleats to attach slotted caul guides made from 3⁄4“-thick plywood. Then I place a scavenged mattress box spring adjacent to each slot. The guides and springs hold the upper cauls at the ready.

Veneering jobs go much more quickly now. I begin work on the riser-supported end of the workboard by preparing and gluing up the veneered panel between two 3⁄4“-thick MDF or plywood platens covered with glue-resistant paper or plastic. Then I slide the sandwich underneath the waiting cauls, and clamp everything down. — George Murphy

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.