We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Making long, perfectly straight cuts with handheld power saws, such as jigsaws and circular saws, can be a real challenge. They aren’t difficult when a straightedge is used as a guide, but putting that straightedge in the right place can be. With kerf jigs, you can set up long cuts in seconds.

Making long, perfectly straight cuts with handheld power saws, such as jigsaws and circular saws, can be a real challenge. They aren’t difficult when a straightedge is used as a guide, but putting that straightedge in the right place can be. With kerf jigs, you can set up long cuts in seconds.

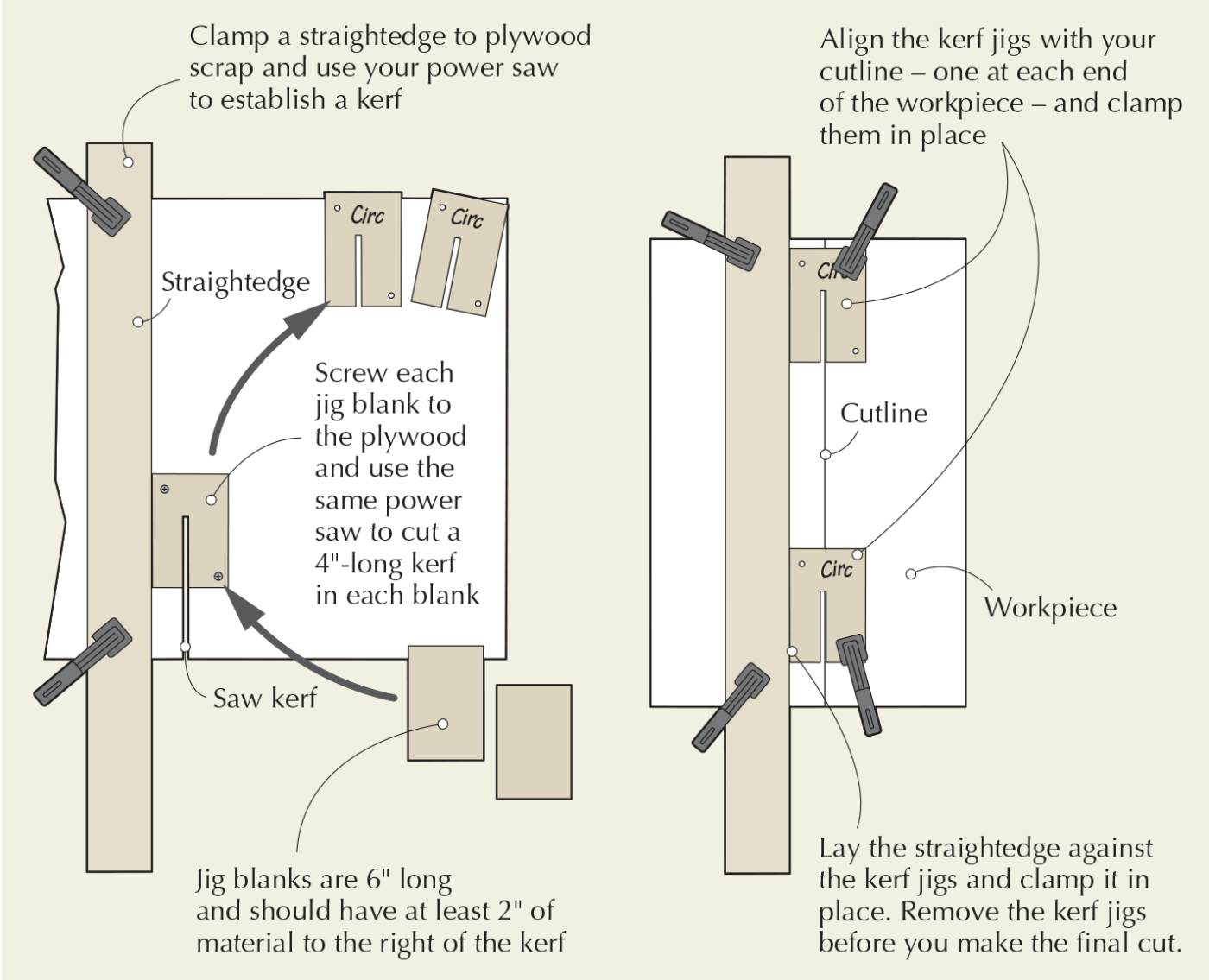

Here’s how to make them. Clamp a straightedge to a sufficiently large piece of plywood. With your power saw pressed against the straightedge, make a short cut in the plywood to establish the path of the kerf. Next, cut two rectangular jig blanks out of 3⁄8” plywood or other stock. Each piece should be about 6″ long and about 2″ wider than the distance from the straightedge to the kerf. Kerf jigs are only accurate with the saw that created them, so mark each piece on the top side according to the saw you’re using (e.g. “JIG” or “CIRC”).

Position one jig blank flush against the straightedge, several inches from the near edge of the plywood, and secure it with two countersunk screws. Keep the screws well away from the path of the kerf. Use the same power saw to cut a 4″-long kerf in the blank. Unscrew the blank, attach the second blank, and make the same cut.

To use, align the kerf jigs with your cutline, and place them at opposite ends of your workpiece. The kerfs should either straddle or be positioned on the same side of the line. Clamp the jigs down firmly.

Next, lay a straightedge flush against the kerf jigs and clamp it in place. Remove the kerf jigs, and you’re ready to make a perfect cut. –Sam Smith

Former editor Christopher Schwarz demonstrates the winning trick from the August 2010 issue of Popular Woodworking Magazine. This trick shows you how to make two clever blocks that make it easy to set up a circular saw or jigsaw to ride accurately against a fence.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

This jig is not just unique to the saw, but may also be sensitive to the setup. When using a similar jig with my circular saw, I was frustrated with inconsistant results. Digging deeper I found that even though my blade was square to the work, changing the height of the blade caused a shift in the cut line. I still use this technique, but I set up the saw for the cuts I will be making before making the jig. Any changes in setup after that, means that I have to retest the jig and redo it if needed.