We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

I recently ran into a turning dilemma when my wife asked me to make her a quick, inexpensive lamp base. I decided that a two-piece base would do the trick, attaching a long, narrow “neck” to a short, wide base for good footing. Shaping the pieces on the lathe would be easy. The challege was creating a hole through the axis of the neck to house the lamp cord. The piece was more than twice as long as my longest drill bit and I didn’t want to buy a special bit for a one-time use.

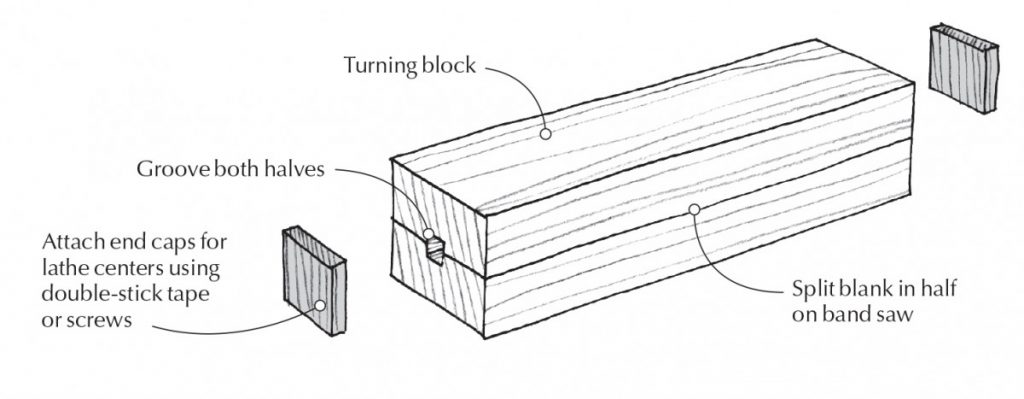

To do the job, I ripped the squared turning blank in half on my band saw, lightly jointed the sawn surfaces, then ran a shallow groove down the inside center of each half. I glued the two halves back together and temporarily attached scrap wood “end caps” with heavy-duty double-stick tape. The caps provided a surface for my lathe centers to bite into. (You could add screws for extra security if you like.) When the turning was complete, I pried off the caps and finished the project. Because of the band saw’s narrow kerf, the glue line was virtually invisible. I saved some money and earned some points with the wife at the same time. — Greg Strately

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.