We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

A few weeks ago one of our remarkable 8th grade students approached me during class and with a sad face as he presented two pieces of steel that just a few moments earlier used to be a vintage socket chisel. He remorsefully said that the chisel broke while he was shaping a round tenon at the end of his stool’s leg. I was quite surprised that the chisel broke off like that. Chisels in my experience don’t break unless they’re forcefully leveraged beyond their ability. But then again, I wanted to give my student the benefit of the doubt, after all he worked so carefully on his project, and I never saw him abuse a tool. So I concluded that perhaps that chisel was doomed to break at some point, and it was just the misfortune of this 8th grader that it happened on his watch.

A few weeks ago one of our remarkable 8th grade students approached me during class and with a sad face as he presented two pieces of steel that just a few moments earlier used to be a vintage socket chisel. He remorsefully said that the chisel broke while he was shaping a round tenon at the end of his stool’s leg. I was quite surprised that the chisel broke off like that. Chisels in my experience don’t break unless they’re forcefully leveraged beyond their ability. But then again, I wanted to give my student the benefit of the doubt, after all he worked so carefully on his project, and I never saw him abuse a tool. So I concluded that perhaps that chisel was doomed to break at some point, and it was just the misfortune of this 8th grader that it happened on his watch.

When Ron Hock saw the broken chisel on my Facebook page he wrote: “I can’t tell from the photo but does the broken surface “sparkle”? I ask because properly hardened steel, when broken, will have such fine grain that it will look like gray primer paint. If it’s been overheated, it will have visible, sparkly grains. Overheating causes large grain growth that weakens the steel…..”

Later that evening I took a picture of the crosscut breakage area and shared it amongst my friends on Facebook. Within hours Ron Hock, who is an authority on making, sharpening, and anything to do with steel for cutting wood, wrote to me and proposed that I should look closely at the broken surface.

He wrote: If you notice big, rough and sparkly particles – it means that this chisel had been inadequately hardened and was probably overheated. Overheating causes large grain growth that weakens the steel. On the other hand, a broken surface of steel that had been properly hardened will look like fine-grained mat-grey primer paint. If this is the case, he said, you will be able to regrind and recommission the chisel.

Following Ron’s suggestion I looked closely at the breakage area and concluded that it did look like smooth and mat primer gray. So the next step was to regrind the chisel to form a bevel.

For many reasons I prefer the hollow grind technique when dealing with chisels and plane irons. In my school we have an 8” grinder equipped with two aftermarket grinder tool rests by Veritas. These tool rests are quite fantastic as they allow me to safely grind almost any imaginable bevel angle one can think of. However when I laid the chisel upside down on the tool rest platform I discovered that the socket bolster of the shortened chisel prevents me from reliably sliding the chisel right and left on the grinding platform. I did not have any issue with this chisel before, but now, as the chisel lost about an inch and a quarter from its length, the conical socket made contact with the aluminum platform and prevented me from sliding the chisel in a secured manner.

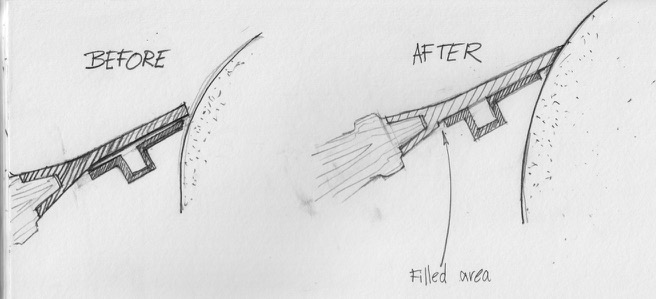

So what to do now? I looked at the transition area between the rectangular blade and the conical socket and thought that if there was enough “meat” inside the socket, then I presume that I would be able to file some steel away and thus extend the surface of the chisel’s top surface enough to allow it to rest flat on the grinding rest. And that’s exactly what I did. I picked up an Inox file (a type of file made by Grobet USA which is, as far as I can tell, the toughest steel file in existence, with a Rockwell hardness of 72HRc) and began reforming the chisel. I believe that other files could have done the job too, but because I was not sure how hard the flat part of the chisel was, and since I did not want to risk damaging one of my day to day files, I decided to bring out the “big guns.” After enough steel was removed by the file I turned to a flat diamond stone to complete the flattening process. All that time I made a conscious effort to keep the top of the chisel parallel to its bottom surface.

With the reformed geometry of the top completed I was ready to regrind the bevel. It took me a few minutes on the grinder followed by a quick touch up on our flat diamond stone and strap, and the chisel was back in business.

Although the new chisel was demoted from its rank as a bench chisel to a mere butt chisel, the restored tool is of utility in our class and will hopefully continue to serve us for years to come.

If you are looking to buy Inox files you can find them at Contenti, which typically has a good array of models in stock.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.