We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Truly imaginative designs. The Noden Inlay Razor changed the way we look at inlay banding. The process is quick to complete (and addicting), and the only limitation is your imagination.

Tool: Noden Inlay Razor

Manufacturer: Noden

Price: $149

Seldom does a tool come along that changes how we look at a woodworking technique, but the Noden Inlay Razor does just that. The Inlay Razor, designed by Adjust-A-Bench inventor Geoffrey Noden, allows you to make an unlimited variety of inlay bandings as quickly as you can prepare the wood.

Although the process looks as if it might be slow, the work glides along easily. In fact, the process to create straight or curved banding is as addictive as it is creative.

While the tool itself is very simple, the idea and the design of the cutters used to slice the wood are outstanding and a bit mind-bending. The concept is light-years ahead of its time, but the cutting blades are decades old.

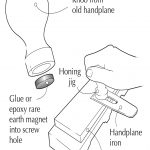

The cutters are wooden blocks that hold double-edged razor blades, the kind that your grandad shaved with years ago.

That’s money. The cutters make this tool. Cut a wooden block to nearly any profile, affix a razor blade in between and you’re ready to work.

The blocks are bisected by kerfs that are straight, rounded, curved or whatever shape you can imagine, as long as you can bend the razor blade to fit the profile (sharp corners are difficult, but can be accomplished if you break the blade). The blades, slipped between the block halves, are glued in place with just a small edge protruding from the wood. That razor’s edge slices the wood pieces to size.

The razor-embedded blocks are simple to switch in and out, but how and where you position the cutter influences the actual cut. To accurately repeat your designs, keep detailed records. Also, because the blades are delicate and wear out over time, you may need to duplicate the designs to create continuous runs.

The razor cutter should cut through thin veneer, but Noden has a completely different idea that again shows his inventive passion. He uses 1⁄16“-thick slices of end-grain wood as the inlay material. This material is easily sliced by the razor and affords the opportunity to use exotic woods and woods seldom used in furniture production without a huge outlay of cash.

To add to the already abundant design options, the Inlay Razor’s cutting arm rotates on the tool’s base. It’s possible to swivel the arm to 60º left or right of center to further influence the design.

Included are four pre-made cutters (straight, arched, S-shaped and cornered – think mountain top), tweezers and a video tutorial. In the tutorial, Noden demonstrates how to use the tool, prepare materials and create your own shop-made cutters.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.