We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Tool: PM1500 Bandsaw

Manufacturer: Powermatic

Price: $2999

Nothing beats a powerful bandsaw for milling boards from a log, roughing out massive blanks for turning or carving, or resawing wide flitches from dry timber. Making tough cuts like these in wood 12″ thick or more has traditionally been a job for commercial 18″ bandsaws, but a growing class of intermediate-size saws (between 14″ and 18″) has started to buck this tradition.

Powermatic’s new PM1500 bandsaw is a member of this class, but only nominally. It’s actually larger and heavier than most 18″ saws, has greater resaw capacity—and is more expensive. It’s almost as if Powermatic set out to make an exceptional 18″ saw with everything but 18″ wheels.

High end and heavy-duty

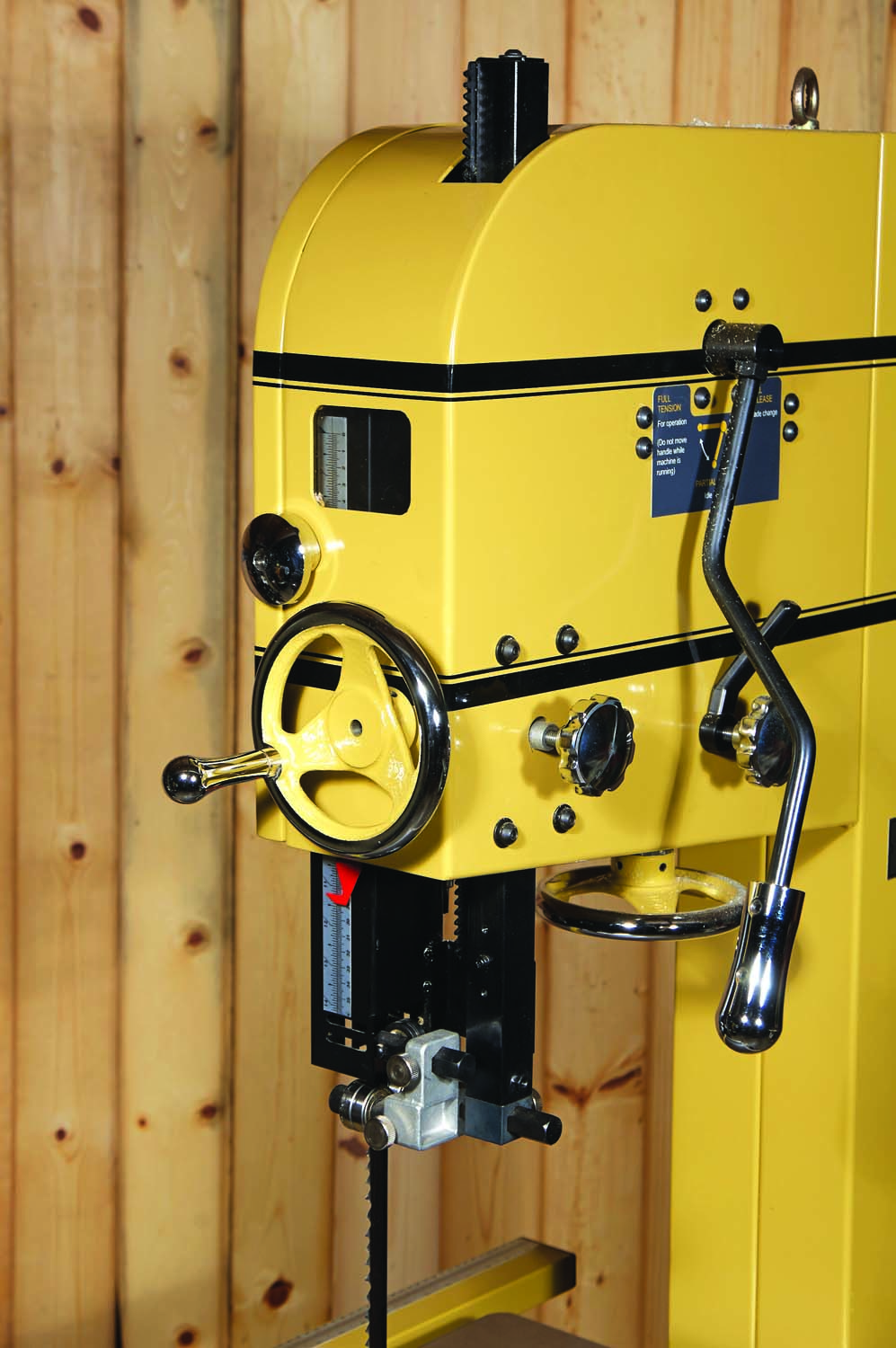

Always within reach, the blade tensioning lever features an electrical interlock that will not let the saw turn on unless the lever is set to the full tension position.

The PM1500 is the second saw in Powermatic’s super-premium bandsaw line, which also includes the flagship PM1800 18″ saw. Like its big brother, the PM1500 is designed to have all the features, convenience and performance a user could want. I think of these saws as the luxury sports sedans of the bandsaw world.

Right out of the crate, the PM1500 impresses. It’s beefy welded steel construction, large cast iron table and sizeable 3hp motor makes it tip the scales at almost 400 lbs. To be honest, I was much happier about all that frame-stiffening, vibration-absorbing mass once I managed to wrestle the PM1500 safely off its pallet and into a sturdy mobile base.

Performance to match

Bright yellow tires make the blade easy to see while adjusting its tracking and indentations make the cast iron wheels safe to spin. View windows allow monitoring the blade’s tracking and tension while the saw is running.

Turn the magnetic power switch and this saw continues to impress. The switch itself contains a safety disc. When the disc is removed from its slot, the saw can’t be turned on. The disc contains a strong magnet, so it’s really easy to remove and stick close by on the saw whenever you have the cabinet doors open or are making adjustments to the saw. This disc is one of the saw’s many thoughtful safety features.

The PM1500 operates smoothly and quietly. It can barely be heard over the air rushing through its two dust collection ports. As for vibration, even when mounted on a flexible mobile base with soft tires, this saw still passes the nickel test—and even the penny test. Balance a penny on edge on the saw’s table and it says on edge from start-up through full coast-down. And thanks to its powerful motor and massive cast iron wheels, I never felt the PM1500 slow down or falter while cutting, no matter how large the stock or hard I pushed. The blade’s ability to slice and clear wood from the kerf is the only factor that limits the cutting speed.

Powerful drivetrain

The foot brake shuts off the motor and stops the drive wheel within five seconds.

The PM1500’s 240 volt, 3hp motor, requires its own 20 amp circuit. The motor’s 55 amp starting draw cranks the saw’s heavy iron wheels up to speed almost instantly and it runs pretty efficiently, with a full load rating of 12 amps. Tool-free motor belt tensioning adjustment is accessible from outside the cabinet.

Because of the wheels’ momentum, the saw takes about 35 seconds to wind down—that’s a long time to wait before backing out an errant blade or removing a small offcut. Luckily the PM1500 comes with a foot brake that can stop the blade in about five seconds. Lightly tapping the brake lever activates a switch that shuts off the motor, while continuous pressure brings everything to halt with a friction brake. Besides using the brake to move quickly between cuts, it’s also essential for hands-free shut off (when holding both halves of the large stock you’ve just cut through, for example), to help regain control if the stock slips or the blade binds, and for emergency stops.

Unusual blade length

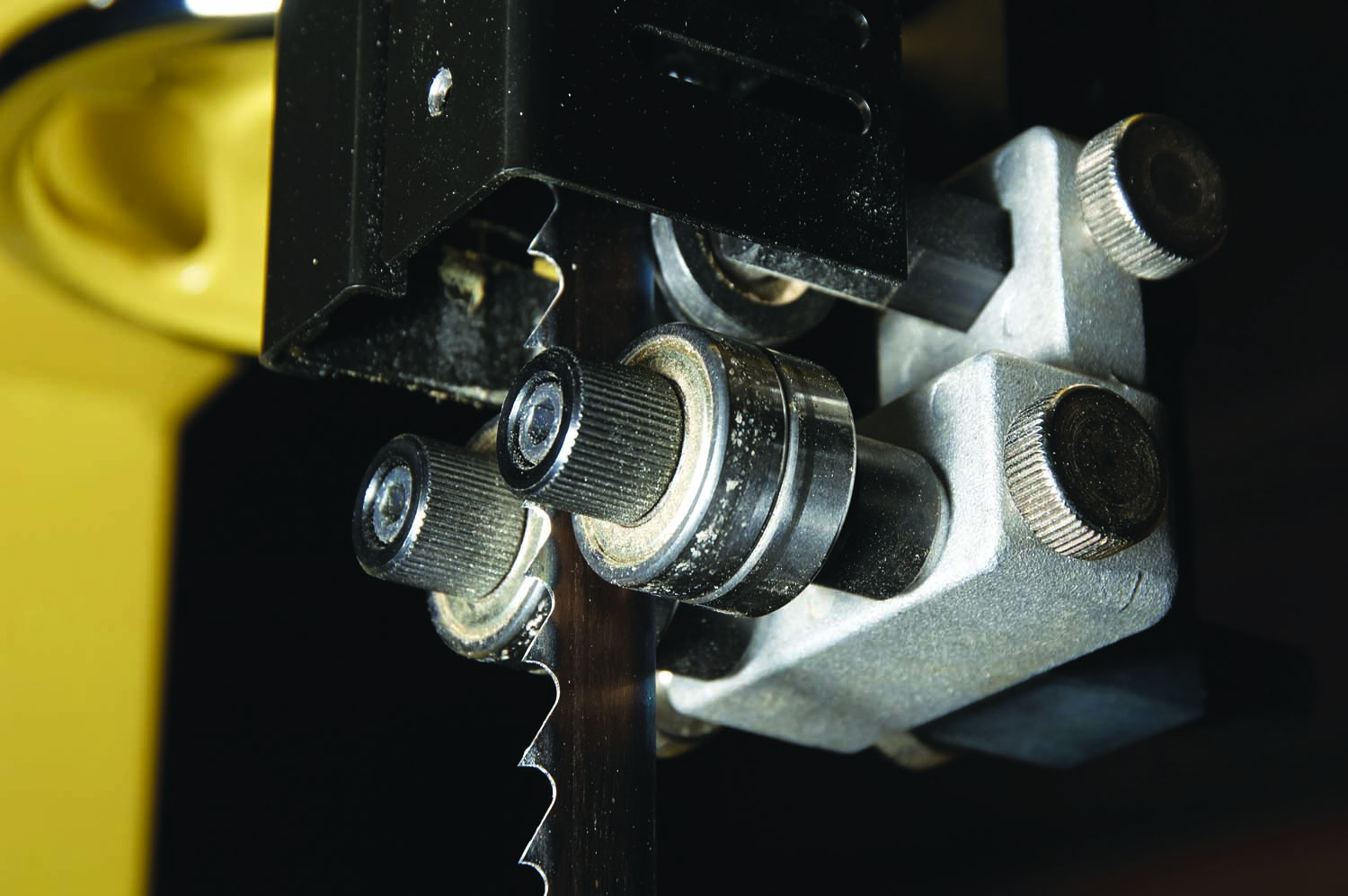

Doubled-up bearings on both sides of the blade are easy to adjust. I drilled an access hole to simplify adjusting the thrust bearing behind the blade.

The PM1500 accepts blade widths from 1/8″ to 1″. But it requires blades that are 153″ long, a non-standard length, so they have to be custom sized. Finding heavy-duty blades that can negotiate the PM1500’s 15″ wheels is another issue. I’ve been operating the saw with Timber Wolf blades, partly because I’ve had good luck with them in the past and partly because the company assured me that the silicon steel in their 3/8″ and 1/2″ rough shaping and 1″ milling/resawing blades (.032″ and .035″ respectively) can handle the stress of bending around such small wheels. (Typically, blades thicker than .025″ are recommended only for wheel sizes of 16″ and up, as they can crack when bent too sharply.) I haven’t had any problems, but thinner 1″ resaw blades are available from at least one other brand, should I ever need them. When used carefully, 3/4″ blades can also resaw accurately. They may be as large as you need to go.

Tension-free tensioning

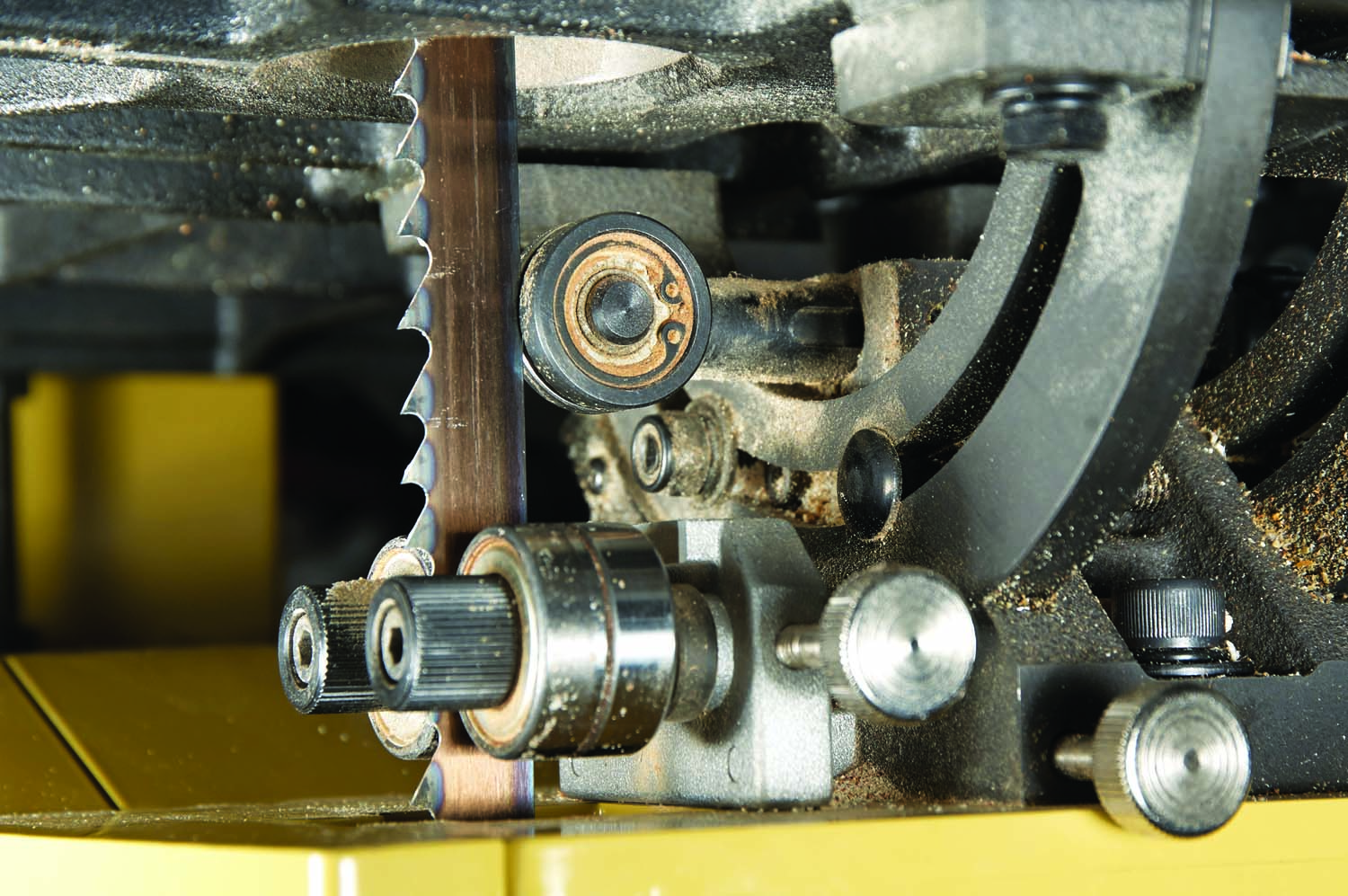

The lower guide assembly mounts on top of the cabinet. Once again, it’s difficult to adjust the thrust bearing, and this time, there’s no simple fix.

The three-position blade tensioning lever is always within reach (unlike some that point up toward the ceiling) and it features an electrical interlock that will not let the saw operate unless the lever is set to the full-tension position. The partial-tension setting relaxes the blade when the saw isn’t being used.

The wheels feature bright yellow tires that make it easy to see the blade while adjusting its tracking. They also have indentations that are inherently safe to grip while rotating the saw by hand during these adjustments.—a nice luxury touch if ever there was one.

Premium guidepost

The large table extends all the way to the cabinet to fully support stock up to 14-1/2″ wide and it remains rock solid while using the slot to guide a milling sled to cut heavy wet logs.

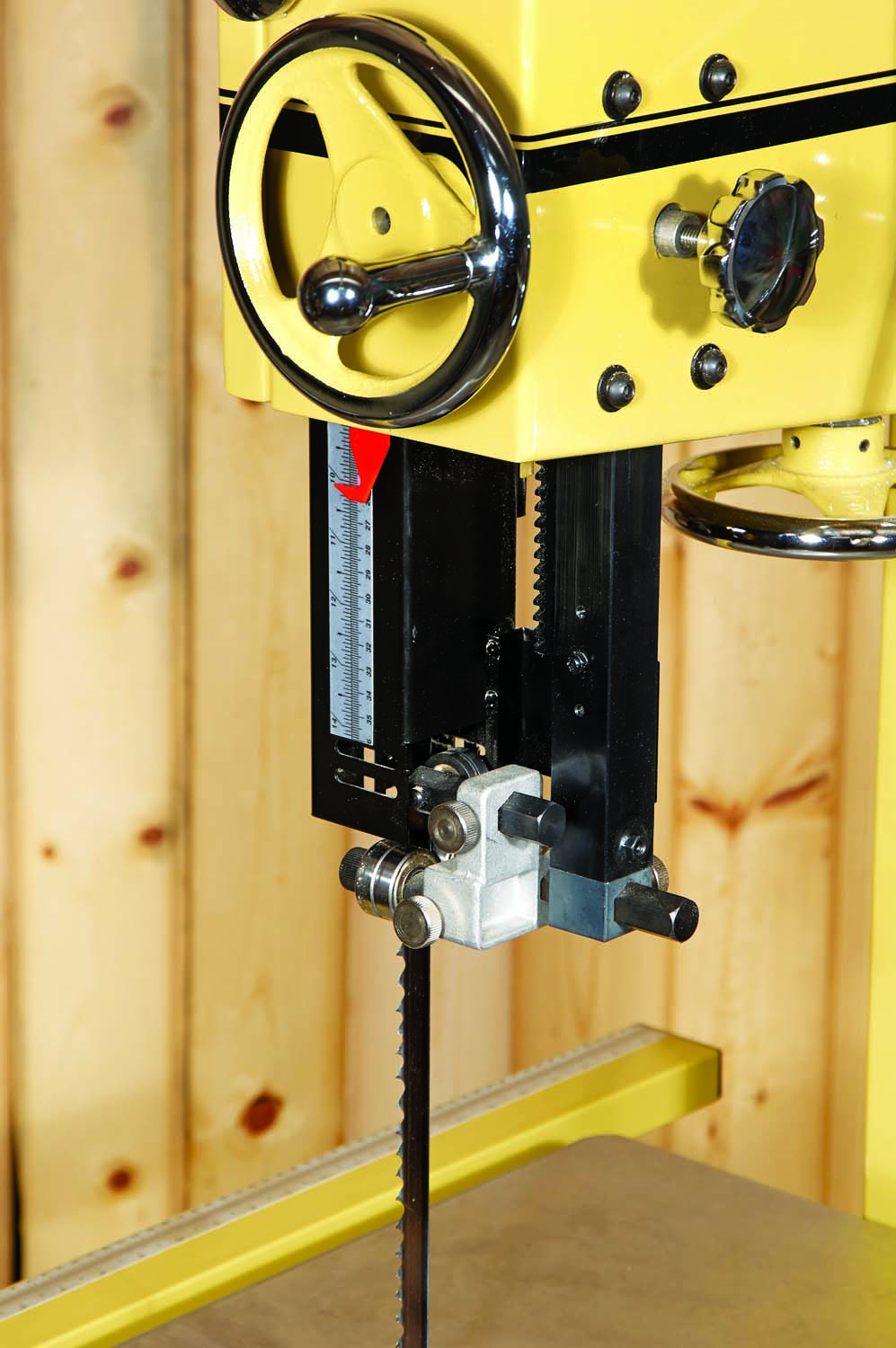

Rather than a conventional steel rod that simply slides up and down by hand, the PM1500’s sophisticated guidepost assembly features rack and pinion gears and it raises and lowers via a large hand crank, with very little variation in the bearing-to-blade spacing between its top and bottom positions. This well-engineered post has three major advantages over old-school guideposts: It keeps the bearing guides in close alignment with the blade everywhere along its 14″ of travel, it won’t crash down to the table when its locking knob is loosened and it can be safely adjusted while the saw is running. In addition, a four-sided blade guard attached to the post completely surrounds the blade.

Robust blade guides

Rack and pinion gearing in the guidepost keeps the bearing guides nearly perfectly aligned with the blade all along the post’s travel. A four-sided guard surrounds the blade.

The PM1500 features ball-bearing guide assemblies above and below the table, each with doubled-up bearings on both sides of the blade and a single thrust bearing with a centering groove to support the back of the blade. All of the adjustments to dial in the bearing guides are tool free, except for the lateral adjustment of the thrust bearings.

The side bearing guide adjustments work perfectly. Knurled knobs provide a sure grip for fine-tuning the bearings when spinning the saw by hand. And if sap buildup makes a bearing start to spin during milling, you can quickly and safely adjust it on the fly by turning the knob with a hex wrench instead of getting your fingers close to the moving blade.

Cutting tight curves or thin rips with the saw made me wish that the lower side bearing guides were closer to the bottom of the table rather than sitting on the saw’s frame. I suspect such a location would prevent every nick I’ve made in the fence or aluminum throat plate due to blade wander.

The setscrew to adjust the thrust bearing on the upper assembly is hidden behind the blade guard. After learning that adjusting this setscrew was a seven-step process, I decided to drill a small access hole for the hex wrench through the guard plate instead. Problem solved.

The knob and locking ring used to adjust and lock the lower thrust bearing are also difficult to reach, because they’re tucked under the table between protrusions that are part of the trunnions. Making this adjustment causes grief with every blade change—it’s the only tedious aspect of using the PM1500.

Big table; tall fence

The PM 1500’s large (21-1/2″ wide by 16″ deep) cast iron table is rock-solid. Anchored by a steel trunnion assembly and positioned at 40″, a comfortable height for both resawing and tabletop work, it extends to the saw body on the left and features a miter slot to the right of the blade. Using a slot-guided milling sled to cut heavy, wet logs concentrates all the weight over the table’s cantilevered edge, but I’ve never encountered any sagging or shifting in the table while making such cuts using logs that outweigh me.

The table tilts down 45° to the right and down 10° to the left for bevel cutting. A rack and pinion gear with tremendous mechanical advantage makes it quite easy to crank this massive cast iron table to the desired angle with one hand. And a locking bolt with a repositionable ratcheting lever handle allows quickly locking in the angle with the other hand. There’s a positive stop at 45° for the right tilt, but in order to be tilted to the left, the 0° stop that normally keeps the table flat must be undone—there’s no way to bypass this stop.

The sturdy T-square style fence has a 6-1/2″ x 19-3/4″ aluminum faceplate that can be attached “face out” for resawing or “face down” to fit under the guide bearings and get close to the blade for cutting thin stock into narrow widths. This fence provides ample support to accurately rip 12″ [14″?] tall boards and shows no deflection when large and heavy stock is pushed hard against it.

To facilitate rip cuts that must be angled to allow for blade drift, a 6-1/2″ tall steel resawing guide pin can be attached to the fence in place of the aluminum faceplate. This pin is good to have because the fence has no provision to allow adjusting for drift without undoing its square setting—and requiring it to be recalibrated it before using it normally again.

Dust collection

Dual 4″ dust ports connected with a 5″ or larger wye provide effective dust collection. A heavy duty mobile base is a must if you plan to move this saw around your shop.

Dust collection is effective when the PM1500 is paired with a 600 CFM dust collector, the minimum recommended size. Dual 4″ dust ports—one just below the blade and one at the floor of the lower housing—capture almost all of the dust. Adjustable brushes against the blade and lower wheel are designed to flick dry sawdust into the air so it can be sucked up, and the tightly-sealing cabinet doors stop air infiltration to keep the vacuum pressure low inside the lower cabinet, a must for good collection.

I got to witness firsthand just how well the PM1500’s dust collection actually works. While cutting thick stock, my dust collection hose accidentally disconnected from the saw. Within minutes, shavings and sawdust were flying into the upper cabinet and piling up in the tracking, tensioning and guidepost adjustment mechanisms located there. Another sizeable pile had started to clog the motor’s wide drive belt in the lower cabinet. Trust me, when you use the PM1500 for milling or resawing, dust collection is mandatory.

Here’s a tip: As soon as sawdust starts snowing down onto the table from the blade opening in the upper cabinet, it’s time to stop and vacuum everything out. Also, green wood shavings and thin strips of wood tend to clog the metal duct screen of the top collection port, so it’s necessary to clear it a few times during every hour of cutting.

The bottom line

The PM1500 is not just built right; it’s overbuilt from almost every conceivable measure. The result is an impressive package with unstoppable power, awesome capacity and an over-the-top set of features. Just what you’d expect from a bandsaw that’s billed (and billed $$$) as a super-premium tool.

Bio

Craftsman and journalist Michael Springer specializes in tool testing and covering the tool industry from his home base in Boulder County, Colo.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.