We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

One of the first tools many get when embarking on our journey into woodworking is a 12” (300mm) combination square. This American innovation is one of our toolbox’s most versatile marking and measuring devices. However, the relatively heavy cast iron and steel combi square is not a tool you carry with you as you move around in the shop; It is more of a sedentary tool to be picked up from the tool rack near the bench and put back on the rack when you finish the marking/measuring. If you (like me) appreciate a portable and smaller square, a loyal companion to accompany you and be as handy as hell, smaller options are also available. One of them – the double square – will be the subject of this blog entry.

One of the first tools many get when embarking on our journey into woodworking is a 12” (300mm) combination square. This American innovation is one of our toolbox’s most versatile marking and measuring devices. However, the relatively heavy cast iron and steel combi square is not a tool you carry with you as you move around in the shop; It is more of a sedentary tool to be picked up from the tool rack near the bench and put back on the rack when you finish the marking/measuring. If you (like me) appreciate a portable and smaller square, a loyal companion to accompany you and be as handy as hell, smaller options are also available. One of them – the double square – will be the subject of this blog entry.

A smaller 6” (150mm) version of the combi-square is trendy among woodworkers, but a cousin of the combination square – the double square – might be the best square to carry in your apron or tool belt pocket most of the time.

The double square (the one below is a new and high-quality tool by Benchmark tools) has a hardened steel blade and a portable cast iron head. Much like the combi square, the double square’s sliding head can be tightened on location along the length of the blade using a knurled nut. If you tighten the head at the end of the blade (or rule), you effectively get a Try Square.

The 6” Double square is handy in probing for squareness. Here, I am using a double square to verify the squareness of this 4” Douglas fir beam.

This is one of the best ways to hold the square against the workpiece’s edge when drawing a right-angle line.

And this is another holding technique.

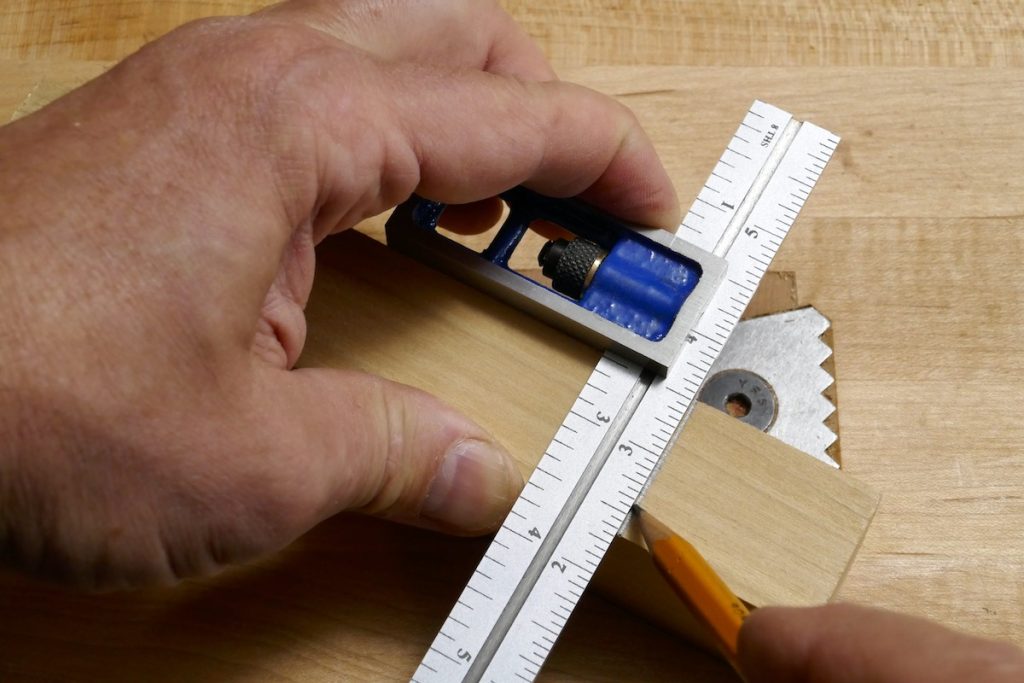

A double square is an excellent tool for denoting and repeating measurements. Set the blade to protrude to the distance you want to mark and transfer that measurement onto the workpiece with a pencil (1,2). If you need that measurement to be at a right angle to the edge of the workpieces, flip the square around, use the blade’s longer portion to guide the pencil, and draw a right-angle line (3).

(1)

(2)

(3)

A double square is also useful when centering parts. When I wanted to place a 4” by 4” segment of a bridal joint over the other, I first eyeballed the placement and then probed with the Double Square’s blade. I moved the square to the other side and rechecked until the top piece was centered. If you make multiple joints like this, you only need to center the first pair. After you do that correctly, lock the blade location and use your double square to telegraph the measurements to the other parts.

There are many Double Square buying options on the market, from the very expensive and highly accurate Starrett to the mass-produced Chinese-made tools that cost around $20. Lee Valley has there own, and so does Woodcraft. iGaging sells them too, and so does Rockler.

I believe that if you get one, you will not let it leave your side.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.