We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

These modern machines are for more than just the space-challenged woodworker.

I’ve got a nice woodshop, but it wasn’t always that way. I started with a contractor saw in the garage. A while later I moved to a bigger house where I could have a dedicated shop. One of the first things I bought for the new shop was a vintage 16“ planer. That planer produced a lot of snipe and the dust chute clogged when I ran wide boards through it. Then I bought a nice 13“ lunchbox planer, but kept the larger one “just in case.” Later, I added a 6“ jointer. I finally had everything I needed to work with rough sawn lumber effectively, but that jointer left a lot to be desired, and I started looking for something better.

A few years ago, a friend got a 16“ jointer/planer combination machine, and he raved about it. He talked on about perfect cuts from the helical cutter head and how nice it was to have a wide jointer. Then another friend of mine told me about his 12“ combination machine and how much he liked it. With limited space in my basement, it seemed like the route to go for me.

A jointer/planer combination machine is just that. It’s a machine that converts from a jointer to a planer, and it uses a single cutter head for both operations. Combination machines have been the norm in Europe for decades, but they’re becoming more popular stateside. And for good reason, beyond just saving space.

Pros

Smaller footprint than separate jointer and planer.

Need to allow space in shop for only one infeed area and one outfeed area

Much less expensive than a comparable set of jointer and planer machines.

Most of these machines are available with helical, carbide cutter heads.

Cons

Expensive. Even though they’re less expensive than comparable separate machines, they usually require a large upfront cost.

Time is required to switch between jointing and planing.

Heavy and difficult to move into basement shops.

Things to Consider

Jointer tables on 16” machines require more effort to raise up than 12” machines.

Will require 220 volt wiring.

European jointer guard takes getting used to, but some people love them.

Ask vendor if there are any upcoming sales or discounts.

Table extensions are not available from all manufacturers, so be sure to check if this is important to you.

Changing over from jointer to planer

is similar on most combination machines, but they’re not all exactly the same. Again, try them out before placing your order.

Upgrade Needs

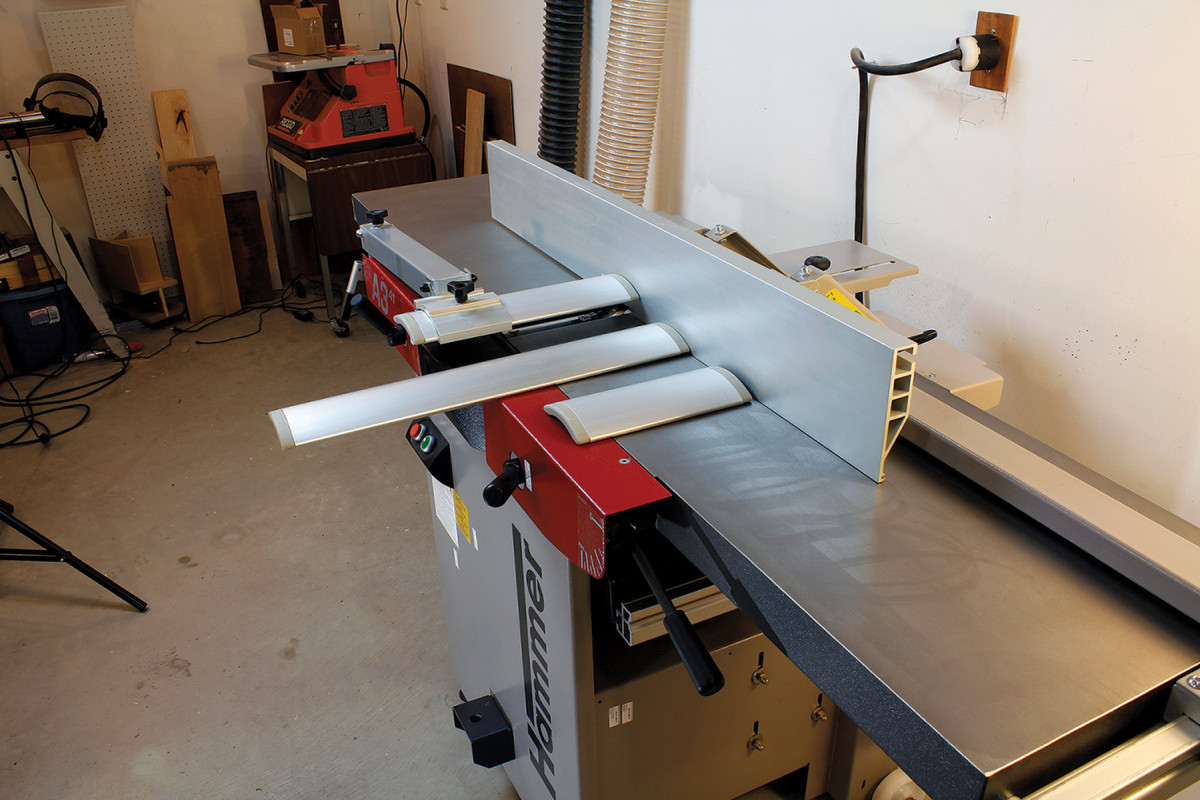

1. The combo machine set up for jointing. The footprint is about 6′ x 3′.

I wanted at least 10“ of jointing capacity and 16“ of planing capacity. I also wanted a helical cutter head. I considered keeping my two planers and buying a 12“ jointer, but I ultimately decided on a 16“ combination machine. The benefits of a combination machine in my space are:

Smaller footprint. I could replace my three machines with just one.

Requires less clearance than separate machines. For example, surfacing a 9‘ board requires nine 9’ of clearance on both the infeed side and the outfeed side. With separate machines you need this clearance for each machine, but with a combination machine you only need it once.

Extra jointing capacity. I would have been thrilled with a 12“ jointer, but 16“ was like going

to heaven!

With a new combination machine I could have a carbide helical cutter head for both jointing and planning and not have to worry about sharping multiple sets of straight blades.

2. I bought an extra European-style blade guard and cut it into two pieces, so I have three different sizes that I use depending on the operation.

Several companies offer 12“ machines, but there are fewer options for 16“ machines. After much research and agonizing over the decision I chose the Hammer A3-41 with a helical cutter head. For me, this met my needs on price, features, and quality. It was far and away the most expensive machine that I had ever purchased, but it was worth it. I found an end of the year special, and it’s a lifetime machine. I won’t need to buy either a jointer or planer ever again.

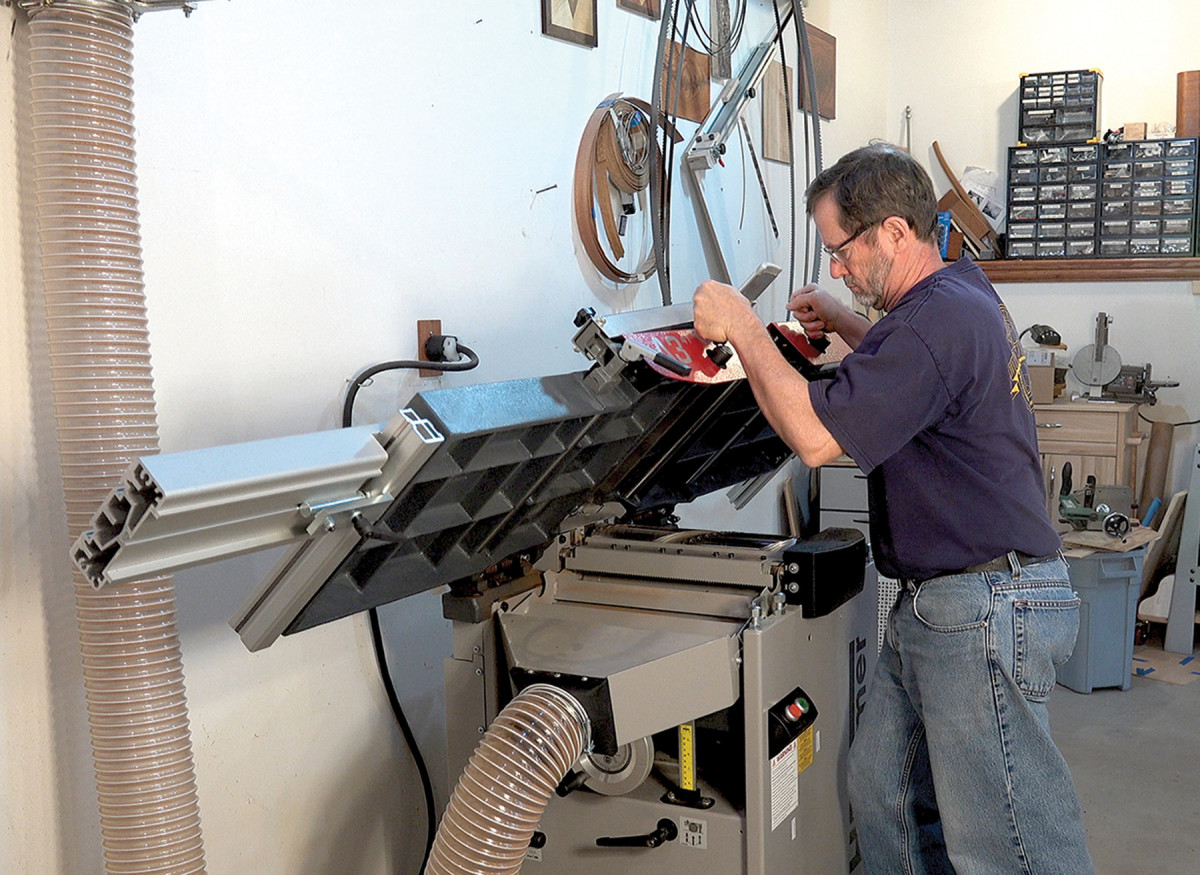

3. With the jointer table up, you can see the helical head used for both jointing and planing

I did add a few accessories. The planer doesn’t have an outfeed table, so I bought a 16“ extension table for the outfeed that’s almost always attached. The jointer table is 70“ long, which is fine for most furniture projects, but I wanted to be prepared for anything so I bought another table extension for that. I don’t use the extensions on the jointer very often and when I need them I also “borrow” the one from the planer (they’re interchangeable), which extends the jointer table to 102“. Hammer also offers a mechanical height indicator for the planer that mounts in the hand wheel, and I added a mobility kit, too. The planer height indicator allows repeatable cuts that are accurate within a few thousands of an inch.

Set Up

4. A European guard does take practice if you’re used to Western, porkchop-style guards.

My machine arrived about two months after I ordered it. It weighs 650 pounds and my shop is in the basement of my house, so I hired piano movers to carry it in and down the stairs for me. Set up was pretty easy. A little clean up, add a plug on the end of the cord, mount the fence and I was ready to go.

5. The combo machine in planer mode with the table flipped up.

I was disappointed initially because there was some snipe from the planer, and I was unable to adjust the jointer outfeed table. I called Hammer and they sent a factory technician from Delaware to my house in Minnesota to fix it. Their customer service is outstanding! Everything was perfect when he finished the adjustments, and things are still dialed in after a year of use and moving it around my shop. I couldn’t be happier with how well everything works.

Jointing

6-9. Changeover is a four-step process. Flip up the table, reposition the dust hood, raise the planer table and engage the drive rollers.

The jointer has an aluminum fence. It looks a bit wimpy compared to a cast iron fence on a traditional jointer, but there have been no problems and it works great. The blade guard is also different than what I’m used to. It has a European blade guard rather than a “pork chop” guard like the one that was on my 6“ jointer.

7.

The guard is a narrow piece of aluminum that stretches over the entire cutter head. Instead of swinging out of the way as a board passes over the cutter head, a European blade guard remains stationary and the board passes under it. Some people love the European blade guards, but I’ve had trouble getting used to it. One of the issues is that the guard sticks out past the side of the machine when I adjust the fence for narrow boards or for edge jointing. My work around for that was to buy an additional blade guard and cut it into two shorter pieces. I now have guards in three different lengths. The shorter blade guards don’t get in my way when I’m jointing narrow boards.

Planing

8.

The planing function feels familiar, like both my old 16“ and lunchbox versions, and it’s easy to use. It doesn’t have an infeed table, but surprisingly, that doesn’t affect how well it works.

Switching from Jointer to Planer

9.

It only takes about 40 seconds, but I still try to minimize how often I change between the jointer and planer. That means I try to face and joint all of my pieces for a build before I thickness them. There are still times where I need to go back and forth, but it’s forced me to be more efficient, which isn’t a bad thing.

Changeover is a Four-Step Operation:

Unlock and raise the jointer table.

Reposition the dust hood for planing.

Raise planer table to desired thickness.

Engage planer drive rollers.

The jointer table on my 16“ machine is kind of heavy and it takes some effort to raise it up. A few of my friends have 12“ machines and theirs aren’t as heavy. The extra effort to lift the 16“ jointer table isn’t a deal breaker by any means, but it is something to consider.

I am very happy with my decision to buy a combination machine. I was surprised how much space it freed up in my shop (despite it being a big machine to start with). Having a wide jointer has improved my work process greatly, and I love the finish off the helical cutter head! PW

Charlie Kocourek is a woodworker and inventor of the Jack Bench Adjustable Height Workbench. You can see more of his work at jack-bench.com.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.