We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

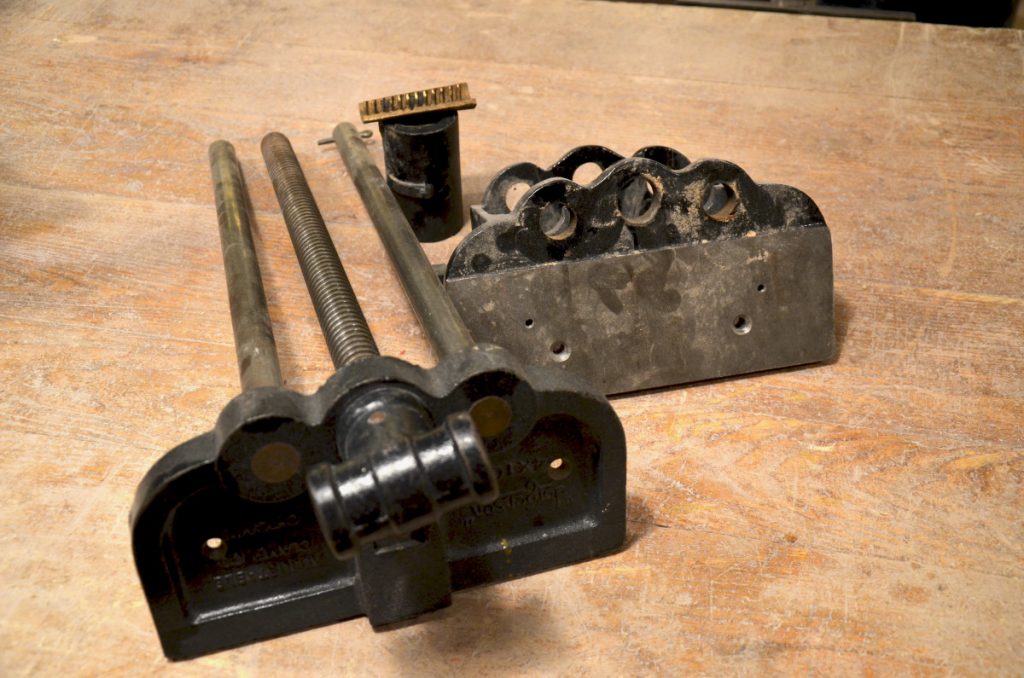

Two years ago I wrote about the ordeal of finding spare parts for the popular (but now discontinued) US-made Jorgensen rapid action vises. Unfortunately, after many years of smooth operation, the vise’s steel acme screw will eventually erode the threaded bronze insert and lose its grip on it. Until a few years ago, when Jorgensen was still making vises in the US, we could have just ordered a new bronze insert. But after the company switched ownership and moved vise production abroad it became just impossible to get these parts.

Two years ago I wrote about the ordeal of finding spare parts for the popular (but now discontinued) US-made Jorgensen rapid action vises. Unfortunately, after many years of smooth operation, the vise’s steel acme screw will eventually erode the threaded bronze insert and lose its grip on it. Until a few years ago, when Jorgensen was still making vises in the US, we could have just ordered a new bronze insert. But after the company switched ownership and moved vise production abroad it became just impossible to get these parts.

The cast-iron barrel and its bronze insert are the heart of the Jorgensen quick-release vise.

Jorgensen’s vise inserts in different stages of wear.

One of our readers, Lee Tuftee, had exactly the same problem with his father’s old vise. The solution that he came up with is quick, easy, and inexpensive. He wrote to me and shared his solution – which in essence is shimming the insert to push the worn-out threads closer to the screw. Here is Lee’s explanations and pictures:

“After trying numerous ideas, I re-worked the problem and came to a fairly easy, permanent, and rather simple solution.

I realized that only part of the threading was worn and if I could move the threads inward to engage the threaded rod more, the vise should work.

So, I cut a piece of sheet metal, roughly 14 gauge +/-, to fit into the insert beneath the bronze piece. Then I filed the bronze insert to allow it to seat at the same level as before. I also ground out the threads to allow the acme threads from the screw to engage more. This was done with a Dremel grinding wheel that fitted into the threads nearly perfectly (it was a gray-colored grinding wheel, a fairly common Dremel bit from my experience). There was plenty of material left after removing a small amount of the insert.”

The shim is just a piece of sheet metal (unknown gauge, 14 or 16?) that I had. I transferred dimensions from the outside of the insert, adjusted it to fit with a file, and let the insert form it on re-assembly.

“When reassembled, the vise worked perfectly and was able to take a man-strength tightening without issue. I also advised my dad to do AT LEAST 1/2 of a turn, if not more, to operate the quick-release mechanism. I figured by the way the mechanism looks to operate, a 1/2 turn would fully disengage the threads and save wear. He used to only go 1/4 turn and you could sometimes hear the threads grinding.

This saved a nice vise from the junkyard and has been working well for over 5 years now. I don’t know if the inserts have become available again, but it may not need it for a long time.

Just wanted to pass this on to you in the hopes of helping out another woodworker to keep good tools working.”

An important aspect of the insert restoration process is addressing the worn-out threads. Lee ground the eroded areas (marked in green) using a Dremel grinding wheel. The erosion of the insert’s threads happens mostly on the left and right edges of the threads so it is beneficial to reform these areas by grinding away the bent bronze and deepening the threads. Lee mentioned that: “…the insert’s radius actually seemed smaller than the screw’s, to the point of never fully seating in the center of the threads when I had it out and laid on the screw. Originally, my dad’s insert was worn out on the edges and had no wear marks anywhere other than the extreme edges of the bronze insert. I feel this step will make a substantial difference in how long the threads will last without being a difficult modification.”

Lee wrote: “The actual bronze inset is seated directly over the shim. After working out the mechanics of the quick release, I advised my dad to give it at least 1/2 turn to release pressure versus his usual 1/4 turn. That allows the carrier to drop the threads from the engaged 12 o’clock position to the 6 o’clock position and not drag the insert threads along the screw.”

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.