We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

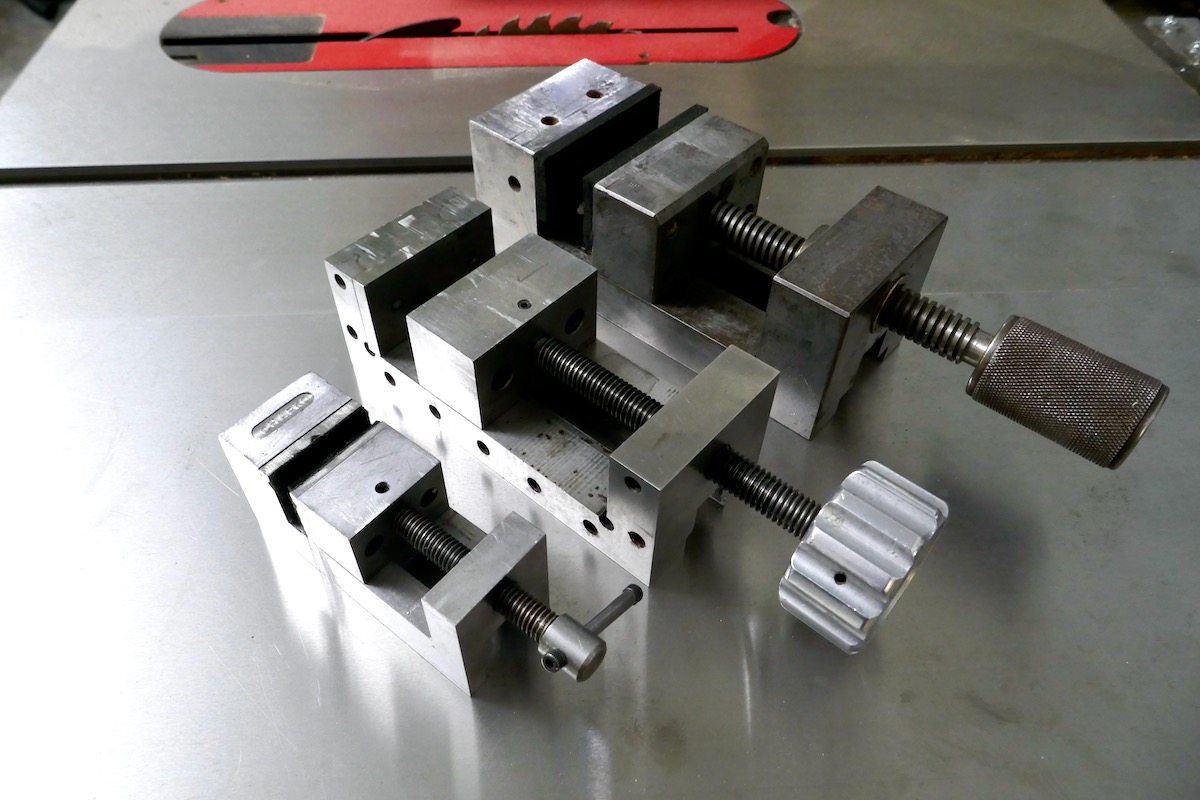

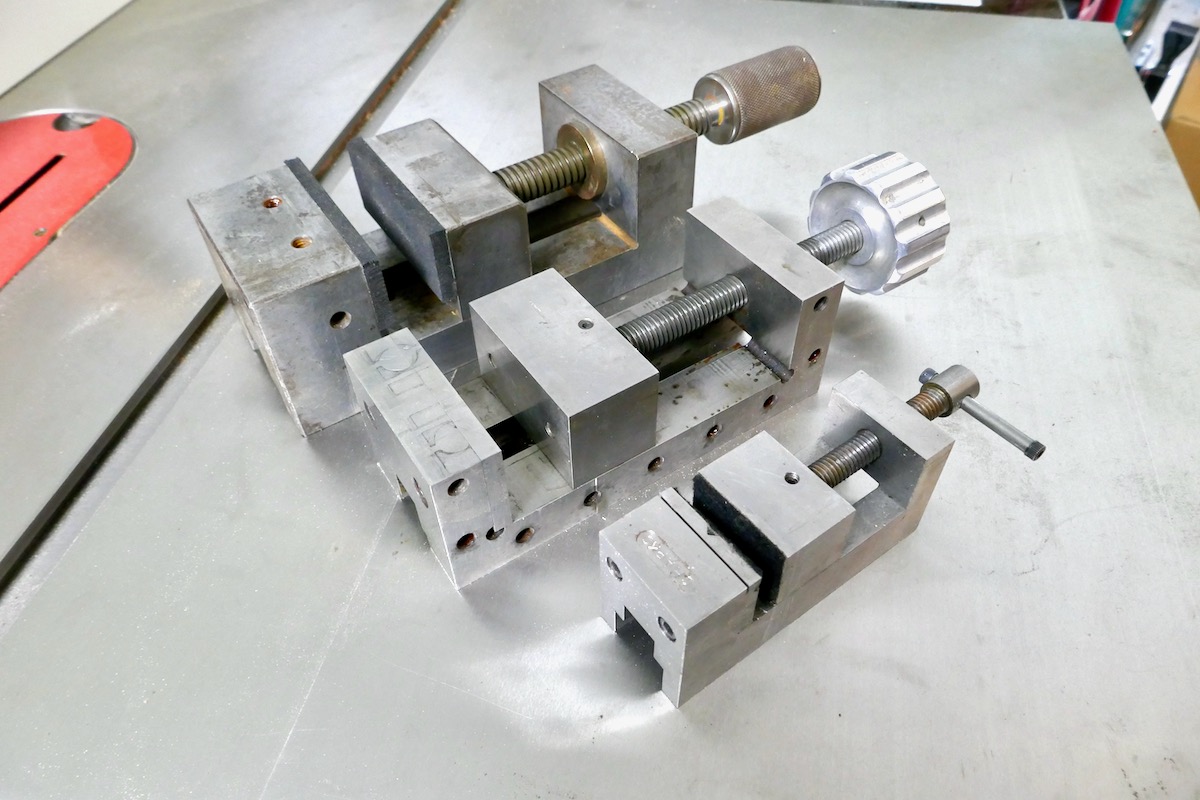

I acquired these steel-body Precision vises on eBay at an excellent price. After meticulous cleaning and proper oiling, they operate seamlessly, just like new.

I confess to having a weakness for collecting Precision Vises (aka Toolmaker’s vises). These machinist tools, bearing names that mirror their meticulous craftsmanship, redefine the game when it comes to securing a workpiece with exactitude during milling or drilling. While their primary domain is metalwork, their versatility seamlessly extends into woodworking, proving indispensable for securing small-scale wood-related projects and hardware. For those on the lookout, woodworking catalogs like the one from Lee Valley offer a basic cast-iron model. Yet, for a broader selection at surprisingly affordable prices—often below $30—eBay emerges as a fantastic source, complementing the options available on Amazon.

The previous owner of the largest vise laminated the jaws’ faces with a soft material. I decided to leave it on as I foresee it coming in handy for holding delicate or irregular-shaped objects for drilling.

Over the years, my collection has evolved to encompass various models of different sizes, each proving its worth across many applications. The cream of the crop boasts a steel construction with a movable jaw featuring V-shaped grooves both horizontally and vertically.

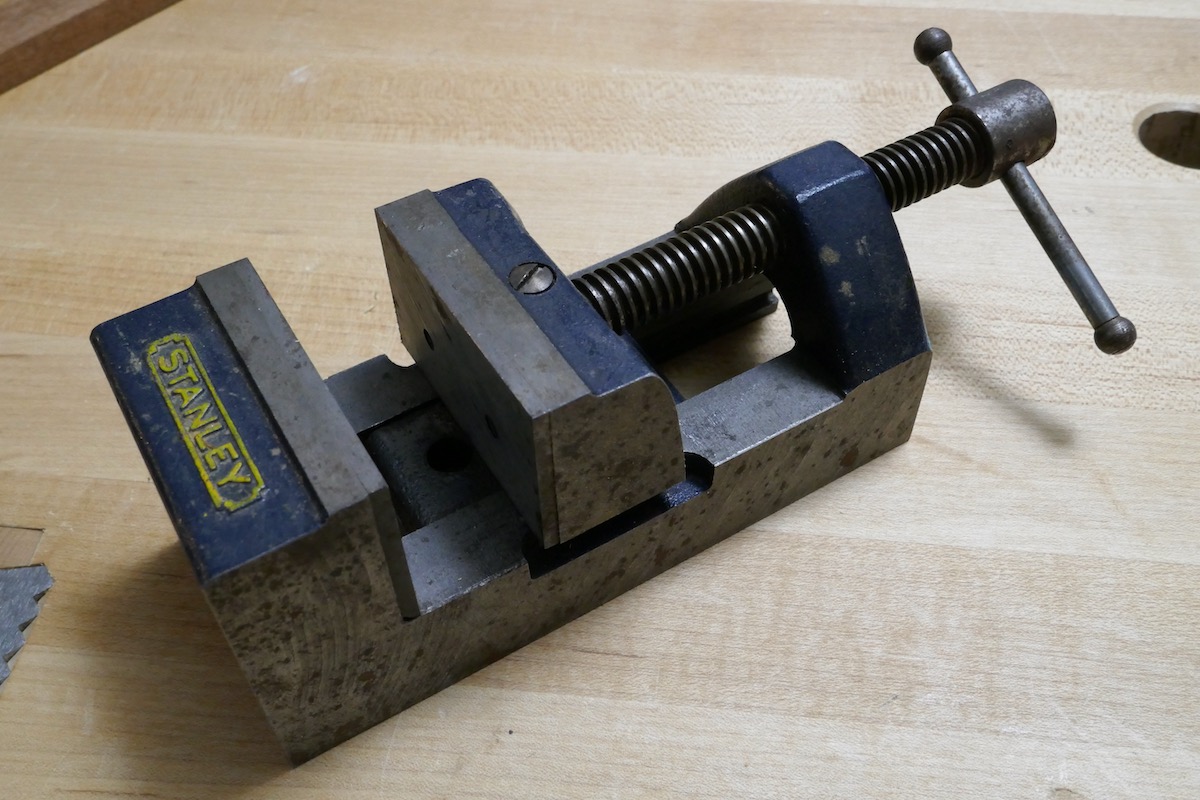

An old cast iron precision vise with replaceable jaw liners from steel by Stanley.

A usual deployment of the Precision vise is to clamp small pats for accurate drilling.

Precision vises shine in terms of convenience, particularly when clamping objects on the drill press or securing them to the workbench. Thanks to their parallel shoulders, securing them in your bench’s vise for drilling or beneath an F-clamp on the drill press table is a breeze. However, their true prowess emerges when handling small metal hardware pieces, like washers or hinges, for drilling, counterboring, and countersinking. Trying these tasks with hand screws made of wood is a safety and effectiveness compromise.

In the photo below, you can witness my precision vise in action—firmly gripping a brass hinge as I prepare to enlarge its countersunk hole before installing it into a box.

Another snapshot reveals the cast-iron precision vise assisting me in drilling plugs from a piece of Walnut.

In this photo, a high-quality, all-steel precision vise takes center stage—positioned on one of its shoulders as the workpiece gets clamped at a right angle to the jaw’s top face. This clamping technique has become my go-to in specific drilling scenarios where placing the vise on its base is either impossible or impractical.

Observe how I’ve strategically placed a wooden block between the jaws, providing crucial support and preventing the washer from succumbing to the pressure exerted during the countersink process. Remember that the block must be narrower than the clamped object to allow the vise to work correctly. It’s a tried-and-true trick of the trade that ensures a flawless outcome.

In my following discussion, I’ll explore additional uses for this compact yet handy vise.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.