We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Have questions about the features of your drill? We have answers. Check out the short video below, then keep on scrolling for more detailed breakdowns of the clutch and gear adjustment settings.

Have questions about the features of your drill? We have answers. Check out the short video below, then keep on scrolling for more detailed breakdowns of the clutch and gear adjustment settings.

What does the clutch on a drill do?

What does the clutch on a drill do?

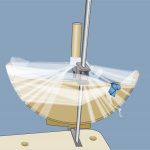

The clutch regulates the amount of torque (power) the drill will generate while driving a fastener. Once the limit has been reached the clutch will disengage the motor, arresting any additional rotations of the drill. In plain English, this is the setting on the drill that helps prevent you from stripping a screw or driving it too deeply into the wood. The lower the setting, the lower the torque, and vice versa. There’s no real guide for what setting you should be using, since factors like wood hardness, fastener size, and preferred depth are going to impact how the drill responds. Many drills also have a dedicated setting for drilling holes, which disengages the clutch entirely for maximum torque. You don’t want to use this setting for driving though, as you could damage the drill or the fastener (or yourself) if there’s too much resistance.

What does the switch on top of the drill do?

What does the switch on top of the drill do?

The switch on the top of the drill goes by several different names. It’s sometimes called the speed switch or torque switch, but the most widely used term seems to be gear switch/selector. Most drills have two settings, though a few have three. Changing the gearing on the drill impacts the speed and torque. The 1 setting is for low-speed high torque, for driving in screws. The 2 setting is for high-speed low torque, for drilling. If your tool has three settings, then 3 becomes the best option for drilling, with the second setting being in-between.

And that’s it! What tool would you like to see us cover next?

Related: The Core Power Tools

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.