We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

We have about a dozen Jorgensen rapid action vises in our woodworking program which as being used by our students all the time. For the most part, my students try to treat our cast iron and steel helpers with respect and avoid over tightening them beyond the necessary pressure needed for holding our workpieces secure. But as with all mechanical contraptions, even the ones that are built heavy and beefy (and generally speaking the US-made Jorgensen were build that way) there comes a time that they are due for a routine checkup, some cleaning and a drop or two of oil. In short, some love and care. From oiling, to handle replacement, and from refitting new jaw liners to the replacement of a worn nut insert, over the years I have gained experience in maintaining and repairing these iconic vises.

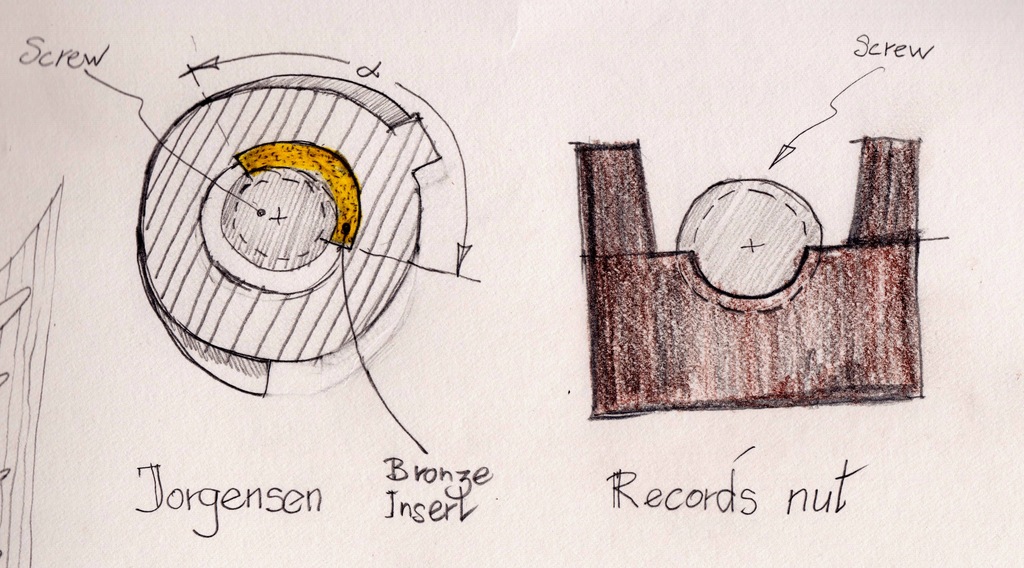

A cross-section of the rapid action Jorgensen nut and screw (left). Notice that the effective thread’s purchase of the bronze insert only engages about a third of the screw’s circumference.

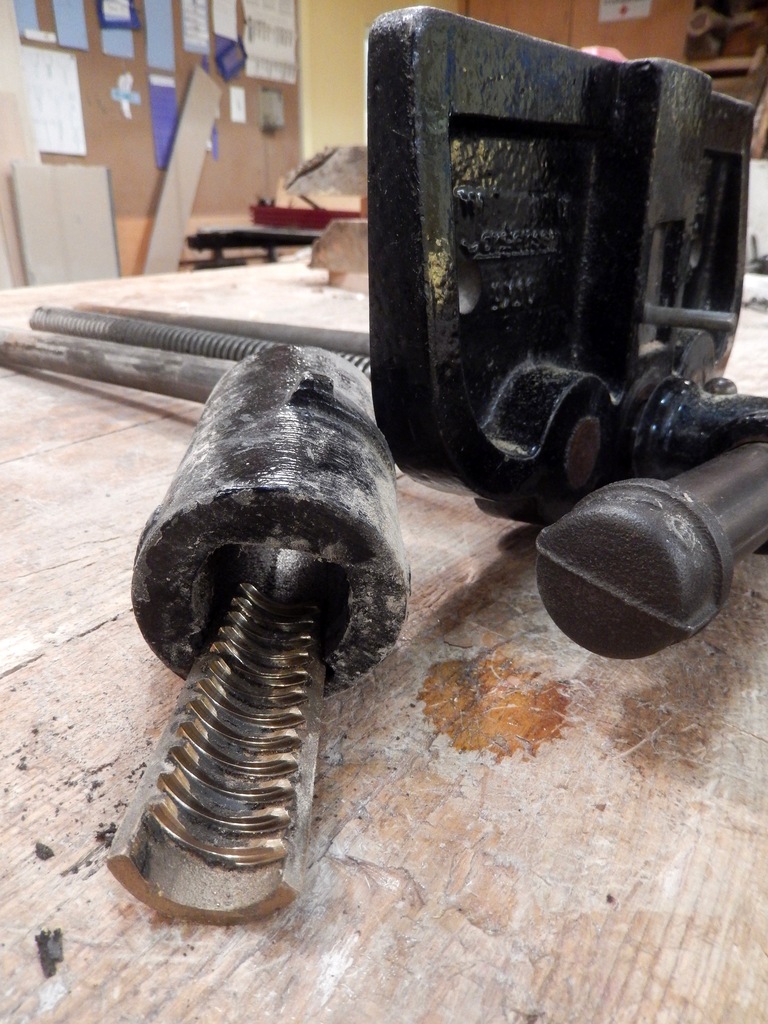

Up until a few years ago, when the Jorgensen vises were still manufactured in the USA, I was able to place orders for the needed spare parts directly from the Midwest parent company, which by the way also made the famous Pony clamps. By far, the most popular part that I had to replace was the threaded bronze insert that enabled the function of the rapid action nut. This part, shaped like a trapezoid grooved vault, is wedged-forced into the cast iron cylindrical nut casing to engage the acme screw. Made from bronze, the insert (rather than the screw) was engineered to become the sacrificial part subjugated to bare the cumulative wear and tear, or in cases were the vise was abusively tightened – to fail before jeopardizing its structural integrity.

As the insert is nearing the end of its life, we can notice a compression, or even a complete erosion of the threads on the right side of the insert.

As the Jorgensen brand switched hands (now it is owned by Arrow Fasteners in New Jersey) we couldn’t order the bronze insert any longer, and as a result, it became paramount to try and maximize the life cycle of each one of them. One of the most effective ways to preserve moving parts is by reducing friction and wear via oiling or greasing. So I began to routinely oil the acme screw, on top of the regular oiling of the two rods (aka guide bars). Little did I knew that this was a mistake. The problem with oiling the screw became clear after one of our vises failed to tighten properly. Every time that a student tried to arrest a workpiece, the screw skipped and slipped under moderate torque. When I disengage the nut and pushed out the insert (I used a round punch to force the wedge insert out) I noticed that the treads are caked up with a black mixture of compacted sawdust and oil. The gunk in between the threads probably pushed the insert out and prevented adequate contact between the acme screw and the nut. Once I cleaned the gunk the threads were able to engage the screw and the vise was back in business.

That experience made me question the validity of the practice of oiling the screw. In most vises, the screw is exposed to wood dust, and if that dust lands on an oily screw it forms a gooey stuff that can be picked up by the nut. A gunky screw will be less of a problem for a continuous action vise were the nut is threaded all around, and might even be able to scrape the gunk before it enters the nut. But any gunk buildup can be detrimental for a partially threaded nut such as the one found on the Jorgensen or on the Record style vises. That said, perhaps a dry lube will solve the problem of gunk buildup since it will not allow the dust to settle and accumulate on the screw.

So as of now, I decided to stop oiling the screws. I hope that the fact that the nut insert is made of bronze, a metal that is historically used in the production of bushings and bearing, will provide enough friction reduction for the tightening action. Furthermore, I intend to clean our nuts routinely, and cross my fingers that the new owners of Jorgensen will offer these crucial spare parts once again. I just hate the thought of throwing away an entire vise just because one little part failed and can’t be replaced.

The insert on the right is slightly deformed but can still function. On the other hand the threads on the far left insert are striped and damaged so it needs to be replaced.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Have you considered using a dry lubricant like graphite?

Thanks for the comment. Graphite lubricant is an interesting idea. I can give it a try. I also thought about using the boelube in its dry-waxy-like form.