We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

For a considerable stretch of time, I’ve championed carbide-turning tools as an accessible and straightforward system, especially for those venturing into woodturning. These tools demand minimal training and yet yield exceptional results.

For a considerable stretch of time, I’ve championed carbide-turning tools as an accessible and straightforward system, especially for those venturing into woodturning. These tools demand minimal training and yet yield exceptional results.

While traditional high-speed steel turning gouges boast ideal geometry for creating flawless surfaces, carbide turning tools present a more robust, blunt geometry. Although not the epitome for rapid material removal or achieving an ultra-smooth finish, mastering these tools is remarkably easy and near error-free. And the best part? They require no sharpening.

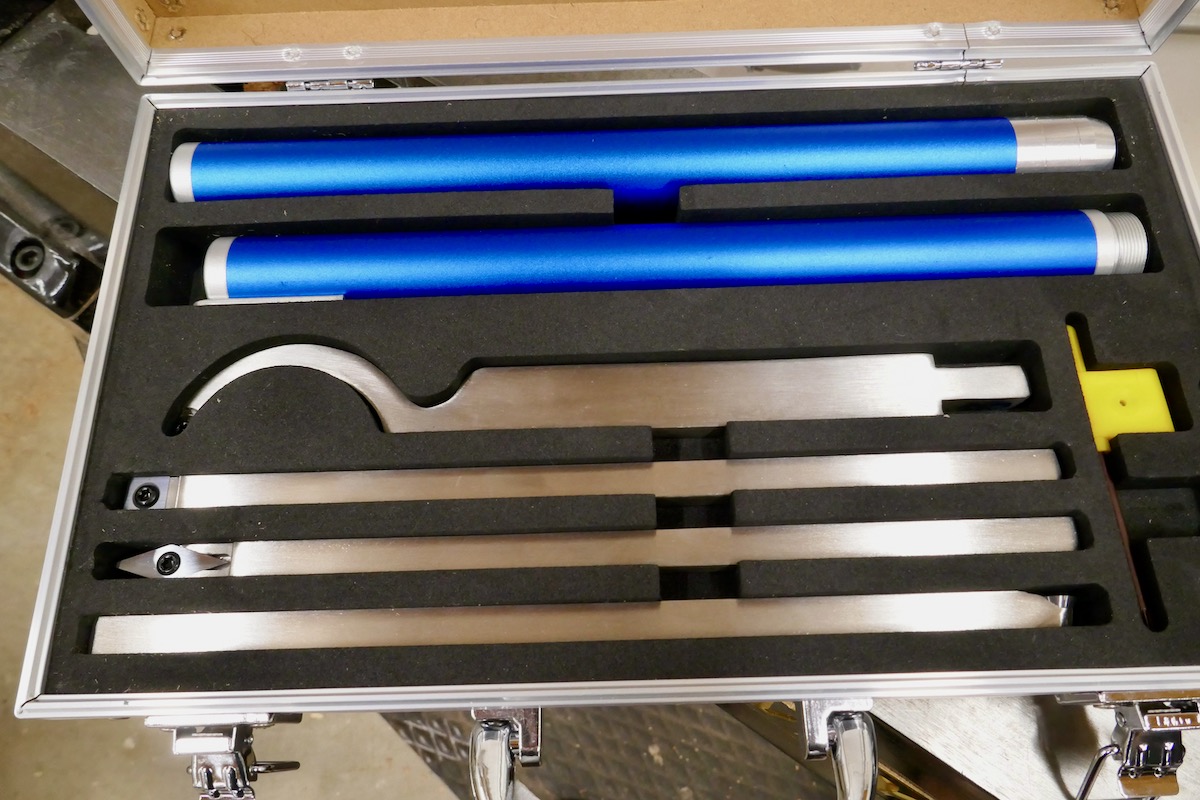

While all carbide turning tool inserts are mounted upon a steel shaft, the handle material can vary between manufacturers. This set, for instance, features aluminum handles, while others might opt for wood. Certain aluminum sets provide both a short handle and an extension sleeve, enhancing reach for larger workpieces.

The magic lies in the hard and resilient tip. Crafted from incredibly tough carbide material, this tip offers exceptional edge retention. It allows extended periods of scraping and shaving wood before needing a replacement. Carbide tool inserts come in various shapes: square, round, or diamond-shaped. If one side dulls, a simple untightening and rotation of the insert present a fresh cutting edge. The inserts are affordable and readily available from multiple suppliers, making these tools a favorite among beginners and intermediate turners alike.

The assembled two-part aluminum handle and the shaft.

This technology, introduced to the market in the last decade, has democratized woodturning, making it accessible to a broader audience. Many who previously perceived woodturning as too complex or daunting found solace in these tools. The traditional mastery of hand choreography and the intricacies of sharpening no longer stood as hurdles.

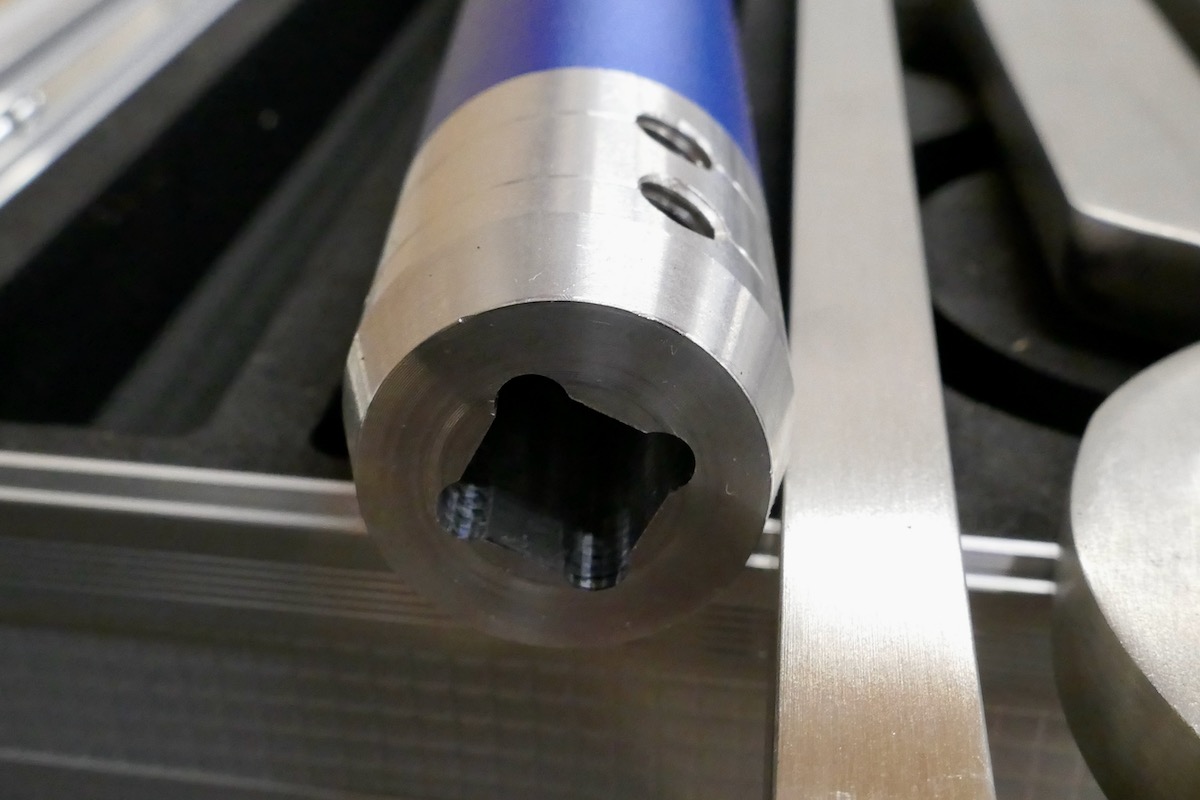

The collet of this aluminum handle securely fastens over the steel shaft using two set screws.

This comprehensive set offers a variety of tool options, each designed for specific woodturning tasks. It includes a square tip for general use, a round tip ideal for shaping coves in spindle work and working inside bowls, a diamond shape for intricate detailing, and a hook-like shaft for reaching inner walls and tight spaces.

The most common carbide tool is showcased here, featuring a square insert at the end of the shaft. This design allows for rounding over stock as a roughing gouge and creating various shapes, including sphere designs and many other intricate patterns.

This handle design guarantees precise control and enhances ease of use for woodturning tasks.

This carbide turning tool has a diamond tip insert for detail work.

This fall, I’m excited to introduce some of my 11th-grade students to woodturning using our mini-lathe and the carbide tool set. If I had opted to teach them using a spindle gouge, it would have entailed a considerable amount of effort and likely led to initial frustration due to the steep learning curve. However, these ‘crude but effective’ carbide tools serve as the perfect entry point, setting them on a potentially exhilarating and enduring journey into the realm of woodturning and woodworking.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.