We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

This versatile hand tool should be every woodworker’s first plane purchase.

As a “professional woodworker” I often get asked what’s the best bang-for-the-buck tool by people getting into this craft. My response is always to ask if they have a good quality block plane. I know, it’s not the big, awesome aircraft carrier-like jointer plane. Nor is it the smoothing plane that makes sexy, fluffy shavings. But when it comes down to it, I feel like you get the most mileage out of a block plane, so that’s where I suggest you start.

Basic Design

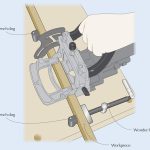

1. A block plane is made up of three main pieces: the body, the blade and the lever cap. This plane also has an adjustable mouth and a depth adjuster.

Before we get into why I feel like a block plane is the most versatile plane in your shop, let’s talk about the physical traits of a block plane. In general terms, a block plane is a small plane (less than 7” long) that has a low blade angle, and the cutter is bevel-up. Usually, they will be between 11/2“ to 2“ wide. These can be coined as apron planes, standard angle blocks, English miter planes, low-angle block planes, pocket planes, or anything in between.

Now, I’m saying this in general terms because there is some debate on if the design, use, or the application makes it a block plane. But for the purpose of this article, we’ll focus on the smaller, bevel-up planes. (I do have one plane that technically isn’t a block plane, but it identifies as a block plane— we’ll talk about that later.)

2. This vintage Stanley 110 doesn’t have a depth adjuster. It still works, but it’s harder to adjust.

In photo 1, you’ll see some features of a quality block plane. It consists of a body, a blade (usually bedded between 12 and 20°), and a lever cap. Higher-end models will have other features, such as an adjustable mouth, a depth-adjuster, and other add-ons. My first block plane was a vintage Stanley 110 shown in image 2. It’s about as bare-bones as block planes come. After using it for years, I can say this: get one with a depth adjuster.

Why They Work Well

3. A sharp block plane is great for trimming end grain. I use a shooting board for support when I can.

There are a few aspects of block planes that make them work well where other planes might struggle. One is the ability to have a lower cutting angle that allows a block plane to effectively plane end grain. On a low-angle plane, the blade is bedded at 12°. When you add in a cutting bevel of 25°, you end up with an effective cutting angle of 37°. Standard angle block planes and most bench planes have a cutting angle of about 45°.

4. For wider end grain trimming, it helps to skew the plane and keep pressure on the toe.

Another thing that helps all planes work better is a tight mouth (scrub planes excluded). On a standard bench plane, the mouth is controlled by adjusting the frog. On a block plane, there is no frog. This design allows the blade to be supported all the way to the cutting edge (less chatter and a smoother cut). However, you can’t adjust a frog that isn’t there to make a tighter mouth. Instead, some block planes will have an adjustable mouth. This allows you to tighten the mouth for fine smoothing operations or open it up for heavier cuts.

The final thing that makes block planes work well is the fact that they’re small and fit in one hand. This means they’re nimble and can reach in tight areas and are excellent at tasks such as planing end grain, leveling joints, small spot smoothing, fitting doors, and the like.

New or Used

5. This specialized rabbeting block plane has a blade that runs all the way to the edge of the body, so you can use it to clean up tenons and rabbets.

Now that we’ve talked about what makes a block plane, let’s talk new versus vintage. Two of my favorite manufacturers are Lie-Nielsen and Veritas. They both make new block planes, roughly based on old Stanley patents. Vintage block planes are, as a rule of thumb, quality. They may need a little fettling to get them in tip-top shape, but are usually available for a song and a dance.

Tuning

6. The small size and light touch of a block plane is very useful in tuning joinery and joints.

Getting a block plane ready for use follows the same tactics as any plane. The sole needs to be flat. This can be accomplished by lapping it on sandpaper on a flat surface. Next, the blade needs to be razor-sharp. Personally, I free hand sharpen on a set of Arkansas oil stones, but you’ll probably get the best results using a honing guide.

The final key is to make sure that the lever cap is free of paint, dust, chips, etc. This will make sure you get firm pressure on the blade without chatter.

Most modern block planes (from reputable manufacturers) will come ready to use out of the box. Some new “budget” planes will still need some work.

Block Planes in Use

7. A specialized toothing blade can do the heavy lifting on wild grain.

Now that you have a ready-to-use plane in hand, let’s talk about using it. There are a few areas where I really like using my block plane and it’s my first choice—end grain, chamfering, refining joinery, and spot smoothing.

End-grain

Paring and trimming end grain is best done with the lowest angle block plane you have. I use two different approaches here.

For narrower tasks, like cleaning up the end of a rail or stile, I like to use my shooting board with my block plane on it. You can see this in image 3. This only works with planes that have parallel sides.

For wider stock, I’ll clamp it in my leg vise. The key is to keep firm pressure on the toe as you plane. I find that skewing the plane will help with the tough end grain. In both instances (shooting board or vise), I always add a slight back chamfer to the stock to avoid chipping out the far side.

Chamfering

8. This small wooden plane made by Bill Carter is a prized possession. Though technically not a block plane, its size means I use it for all the same tasks I’d use any other block plane for.

Chamfering is probably my number one block plane task. It’s just so convenient to reach into my apron, pull out the plane, and quickly put a chamfer on parts (begone loud, dusty router tables!). I usually eyeball a 45° and make a couple of passes until the chamfer is as wide as I need it. Alternatively, if it’s a critical chamfer, I will curl my fingers around the plane and use them as a “fence” to help guide the plane. Start with chamfering the end grain first, then the long grain. That way, any chip out from the end grain cuts will be removed with the long grain chamfer.

Joinery

Tackling joinery is probably the broadest use of a block plane, at least in my shop. I have a rabbet block plane that I use for everything from fine-tuning rabbets to trimming tenons and everything between.

My smaller low angle plane is my go-to for flushing joints as well. When leveling a rail and stile or the top edge of a drawer for example, I tackle the joint from a 45° angle (photo 6). This shearing angle avoids cutting cross-grain on one of the workpieces. While I’m talking about doors, There’s no other tool better suited (in my opinion) for fitting doors and drawers. Holding a door in the face vise, I can quickly make a couple of trimming cuts to bring the drawers to the perfect size (or to shape if something’s out of square).

Smoothing Cuts

Finally, the block plane is a perfect (miniature) smoother. With a couple of swipes, it smooths out milling marks from the edges of boards without breaking out the number 7.

There are also instances where a block plane might be the best plane for smoothing. In particular, when you’re working on curved pieces, such as a cabriole leg or smoothing out a spoon. The small sole of a block plane allows you to follow the curve very well and is a great mid-way tool between shaping and finishing. Unconventional? Sure, but it works well.

Some manufacturers, like Veritas, make toothing blades (photo 7) for block planes. Equipped as such, they can quickly deal with any tear out from wild grain, leaving just a few tooth marks that require a card scraper pass or two.

These smoothing operations, in particular, are where I like to bring in my small plane from Bill Carter (photo 8). Yes. Technically it’s a smoothing plane and not a block plane. But in my shop, it identifies as a block plane because I use it for all my block plane tasks (except paring end grain). It fits in one hand or in my apron pocket and is agile enough to reach into hard-to-get areas. Hence, block plane.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.