We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

One of the strops that I tried in my efforts to find a high-quality yet economic tool was the Lee Valley strop. (Read part 1 of the story here).

One of the strops that I tried in my efforts to find a high-quality yet economic tool was the Lee Valley strop. (Read part 1 of the story here).

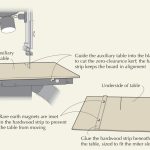

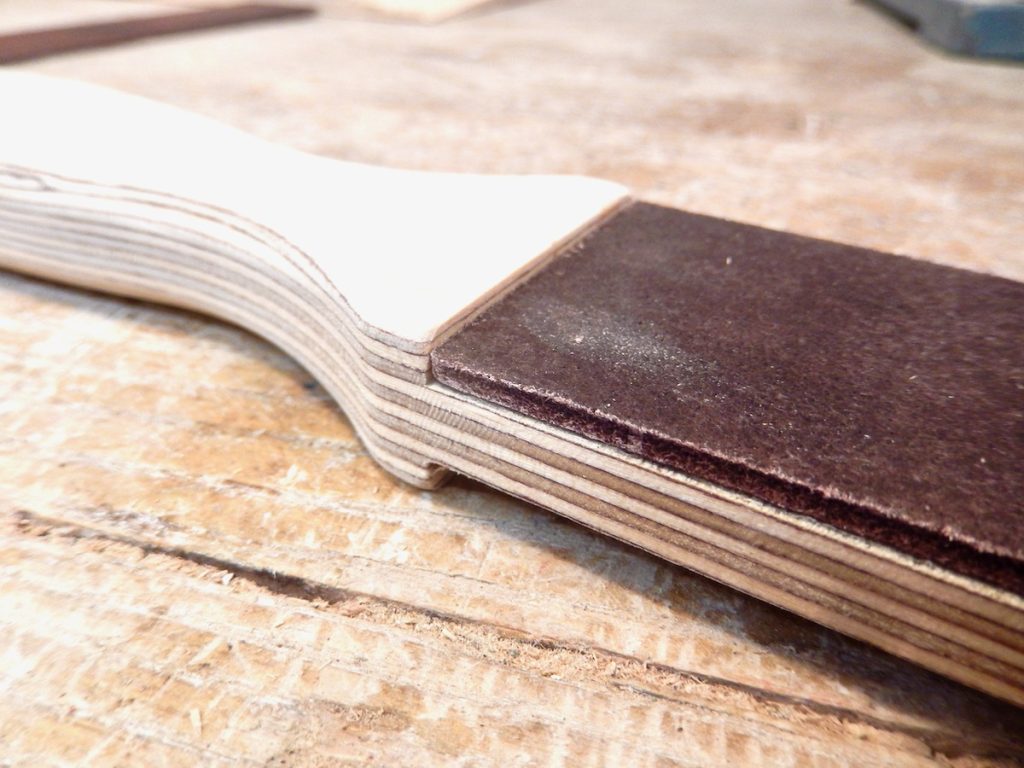

This strop is made of plywood and comes with separate leather strips that need to be affixed to the paddle via pressure-sensitive adhesive tape. After trying it for some time, I must say that I am disappointed. To begin with, I disliked the bendability of the plywood paddle; it is just too thin for its purposes. The second issue and the more important one has to do with the leather quality. After a very short time, the sued side of the strop began to chip off – which turned the surface to look like a badly maintained potholed road in the middle of winter.

The Lee Valley tool could have been a great tool if it had been made from solid hardwood and if a more rigid and dense leather was included.

Make a strop from scratch

As I mentioned last week, the easiest strop can be made from a piece of leather charged with a honing compound. An old leather belt will do, but a scrap of vegetable-tanned leather like this product will be even better.

If you prefer to have the leather glued onto a paddle, first make the paddle and then cut the leather to fit over it. If possible make the leather as wide as the paddle.

If the suede side of the leather is not too flimsy sand the smooth side (to allow it to take glue better) and adhere it to the wood substrate. And if the sued is too loose and frayed, elect to glue it onto the wooden paddle and then roughen out the smooth face with sandpaper to turn it into the sued face.

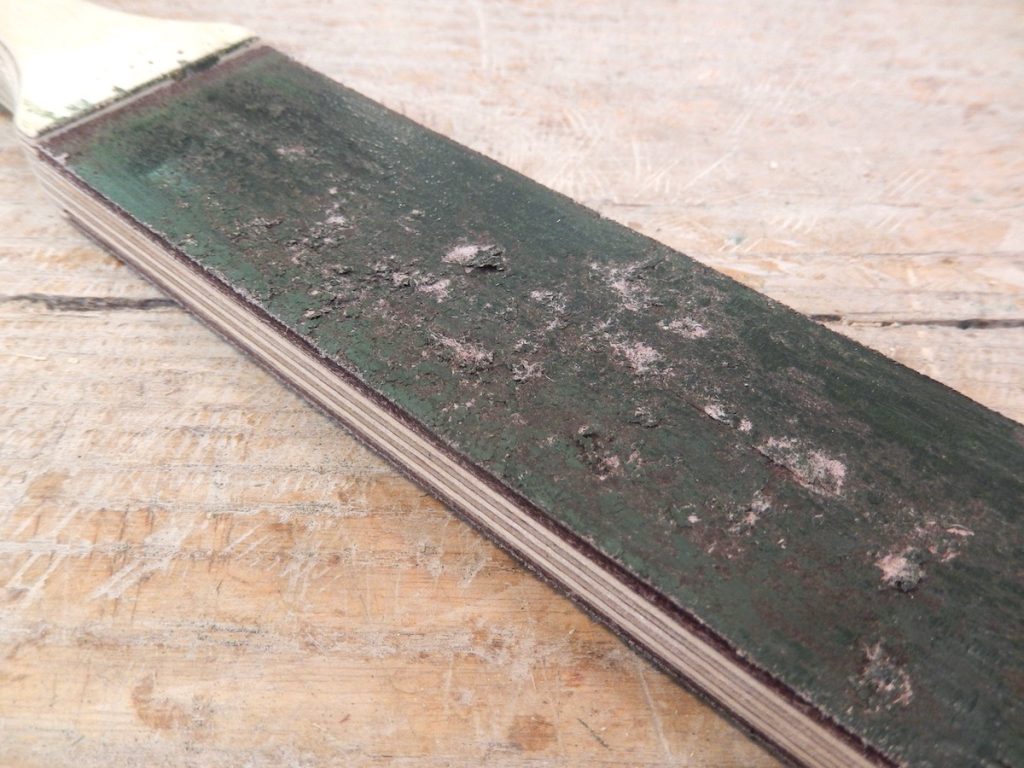

Innovative strop design

To extend the life of the strop I choose to use its entire surface. This is especially important when we strop edge tools that are narrower than the strop. I strop from top to bottom on the right side and remember to alternate and repeat this on the left side.

All of the handled paddle strops that I know have a square foot to allow us to stabilize them at a comfortable angle over a flat surface and strop conveniently. But because these strops have a handle on the other end it is impossible to stabilize them on the handle end to strop on the opposite side and in the opposite direction. Recently I came up with an idea for an improved paddle design that will allow us to stabilize the strop on both its ends. The design calls for two handles that widen at their heels. This flat & square heel will allow us to hold both handles (each one at a time) so we can use the tool from each end. I believe that this design is a winner and intend to give it a try the next time I need to build a strop from scratch.

When I bought our German-made carving knives I had to use a 1200 grit diamond stone to initiate their edge, but after this, the strop was practically the only sharpening system that I used. If you buy the high-quality and superbly sharpened Flexcut knives you will not have to bother with initiating the edge on a stone. The maker does a great job sharpening it in the factory so you could begin carving immediately and only pass the blade on a strop occasionally.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

![How To Sharpen A Gouge [Video]](https://www.popularwoodworking.com/wp-content/uploads/bfi_thumb/dummy-transparent-olcy6s63it1p9yp7uhusjas7c8kahafrhg9su7q9i0.png)