We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

A well-equipped shop will have a variety of clamps for different situations. Here’s our favorites.

A well-equipped shop will have a variety of clamps for different situations. Here’s our favorites.

I think that you’ve probably heard the saying that “a woodworker can never have too many clamps.” Heck, you may have even used that as an excuse (or affirmation) about buying additional clamps. I won’t tell. However, I feel as though a better saying would be “a woodworker can never have too many of the right clamps.” What I mean by that is an entire shop full of clamps won’t do any good if they don’t work for the task at hand.

Now, I know that clamps aren’t the coolest thing in the world. They’re not a sexy, boutique handplane, fancy chisel, or the latest and greatest table saw. However, I think they tend to be one of the last things people think about while buying tools. You would be surprised by the number of shops I walk into full of the newest tools, only to find a hodge-podge of clamps with little thought given to their use or place in the shop ecosystem.

Don’t get me wrong, though. If you find a box of clamps at a garage sale, and you need to have some form of consent to get clamps, I give you my full blessing to buy as many as you can fit in the back of your pinto. However, some of us work with limited shop space and storage for clamps. In this case, I’ve found that being strategic with clamp purchases and making sure that you have the right mix in your shop will alleviate some headaches as you’re working on a project, and getting ready to glue up.

I am going to point out that these clamps are particular clamps and styles that I like to use, and you might find useful. I know clamps can be expensive, and some people are fans of buying mass quantities of cheap, discount store clamps. That’s perfectly fine and acceptable. However, these are the styles that I like and what I prefer to keep on hand.

F-Style Clamps

If I’m in my shop and someone asks me for a clamp, my first instinct is to grab an F-style clamp. This style of clamp is one of the most versatile clamps that you can have around, in my opinion. Not only can you apply a tremendous amount of force, depending on the style, but they’re also available in a ridiculous amount of sizes.

One of my favorite sizes to keep on hand is the mini F-style (the Semble brand is shown here — lower left in the photo). These are my go-to for clamping on stop blocks at the router table, table saw, and miter saw. With a 2“ depth, they also work well for clamping together plywood when you are laminating sheets together.

One of my favorite sizes to keep on hand is the mini F-style (the Semble brand is shown here — lower left in the photo). These are my go-to for clamping on stop blocks at the router table, table saw, and miter saw. With a 2“ depth, they also work well for clamping together plywood when you are laminating sheets together.

For general clamping tasks, a 4“ clamping depth is about perfect. I keep a variety of bar lengths around, ranging from 8“-24“. Depending on the size, these deliver about 800 lbs of clamping force and are the perfect way to apply precise clamping pressure. Not only do these work for clamping parts together during glue-up, but I’ll often use them to hold portable tools to the bench (lower right photo). Generally, the longer the bar on F-style clamps, the more they will flex during use.

I’m not terribly picky about the brand of these clamps, as long as they’re quality. I’ve found that Bessey and Semble are two of the best, in my opinion. I don’t really care for the style that uses a spring trigger on the head. The Bessey and Semble use a cam-type action to lock the head on the bar. I’ve never had one of these slip or “go bad”, whereas I’ve had a few older “trigger” styles that will start to slip. At that point, it’s time they hit the garbage. These tend to be my go-to clamps for most things.

I-Beam Clamps

I know that many woodworkers like to use pipe clamps. I, however, do not like them. I’ve found that gluing up a panel with pipe clamps will almost always yield black marks all over my workpiece. That combined with the heads always spinning and twisting around, and my hands ending up black—that’s a nope from me.

Instead, for my panel glue-ups, or longer clamping needs, I use the Bessey I-beam clamps. I like the heft of them, and the lead screws on the heads are quick to adjust and apply great pressure. When it comes to doing a panel glue-up, such as this mahogany top, the clamps sit nicely on a bench, and I can get more than enough clamping pressure. While I do also like using the aluminum-style bar clamps (such as the ones from Dubuque Clamp Works), I feel like these I-beams have a slight edge in use. The bars don’t bend like the aluminum ones, as the heads are slightly deeper.

Big bar clamps like these start to add up quickly as you buy them, so I try not to go too crazy here. Three clamps are usually good when gluing up a panel, but adding an extra clamp in there is not a bad idea, especially if you like to alternate directions of your clamps as you’re gluing up a panel.

Handscrews

Now here’s a clamp that I feel like is the black sheep in most shops. If there’s a clamp that doesn’t get sufficient love, it’s a handscrew. These clamps are pretty easy to find in flea markets and garage sales, but Jorgensen and others still make them new.

I won’t classify handscrews as a workpiece clamp, per se. Instead, I use handscrews as an extra hand in most instances. They’re great at holding large plywood panels on edge while working on assembly (top photo, below). You can even hold the handscrew to the bench with another clamp. Because the handscrew is a wood clamp, it’s easy to modify the ends of the handscrew for specialty tasks. I have a few different handscrews that I’ve notched the jaws or drilled holes in for holding round parts. As you see in the lower photo, you can easily hold round parts at the drill press or bandsaw while keeping your hands out of the way. If you add a few of these inexpensive clamps to your shop, I think you’ll come to appreciate them.

Parallel Clamps

If the I-beam clamps are my panel glue-up clamp, then I’d label my parallel clamps as my drawer and case clamps. As the name implies, the wide jaws stay parallel to each other as you apply clamping force. These guys are perfect for clamping up cases, drawer boxes, and boxes… really anything that has the risk of being pulled out of square while you’re applying clamping pressure. The wide jaws also spread the pressure out more, so they have less likelihood of denting your workpiece with excessive clamping pressure (I’m guilty of denting parts with both F-style and I-beam clamps).

The new Semble parallel clamps have quickly become one of my favorites, as they have the unique feature that allows the handle to rotate 90° to give you extra torque while clamping. This is a feature that I appreciate, especially once my golfer’s elbow starts to flare up during sawmilling season.

The new Semble parallel clamps have quickly become one of my favorites, as they have the unique feature that allows the handle to rotate 90° to give you extra torque while clamping. This is a feature that I appreciate, especially once my golfer’s elbow starts to flare up during sawmilling season.

An additional feature that is rarely needed, but appreciated when the need does arise, is the ability of most parallel clamps to have the clamp head rotated. This means you can use the clamp as a spreader instead of a clamp. This comes in handy when you need to reverse a glue up when you realize that you forgot to slip a panel in place (ask me how I know).

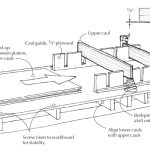

20″ Deep Reach Clamp

Finally, this is a clamp that there’s no substitute for. While technically, these deep reach clamps from Bessey are an F-style clamp, they’re so specialized, unique, and absolutely useful that I felt as though they needed a section to themselves. These behemoths have the ability to reach far inland on a workpiece and apply clamping pressure where others can’t. I find them particularly useful when working on a panel lamination, such as laminating stock together for thick panels, or holding a lid to the top of a case while assembling a project. They also work well on more delicate tasks, such as clamping runners in place in a deep case.

These aren’t a clamp that gets used all of the time in my shop, so a pair of these heifers are about all that I usually need. They are heavy, you can get a ton of pressure out of them, but you don’t want to be lugging them all over the shop. These clamps are available in depths of 10“, 12“, and 20“ (all with 24“-length bars), however, I feel as though if you’re going to get a deep reach clamp, you might as well just get the deepest reach one available.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.