We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

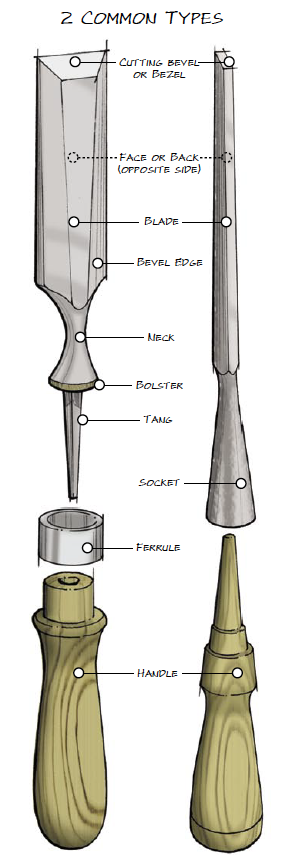

Common Types and Sizes

Bevel-edge Chisel (at left):

Bevel-edge Chisel (at left):

Long edges are ground to an angle to allow the tool to get into tight spaces, such as between dovetails. It is not designed for heavy chopping. A common variant is the paring chisel, which has a longer, thinner blade.

Mortising Chisel (at right):

A thick blade allows the tools to be driven with a mallet and to lever out waste in mortises. One variant is the firmer chisel, which has a thick blade – though not as thick as a mortising chisel – and is designed for heavier work. The butt chisel, another common variant, is typically a firmer chisel with a much shorter blade.

Common Chiseling Techniques

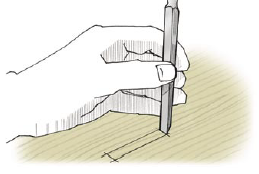

Cutting with the Tool Perpendicular to the Work:

The most important consideration is to position yourself so you can see the profile of the tool and determine if it is indeed at 90° to your work. Use the cutting edge of the tool to define your layout lines before removing the waste inside them, as shown at right.

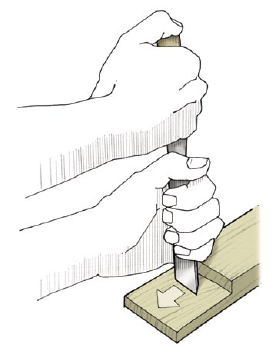

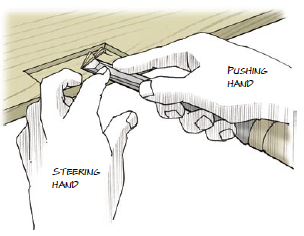

Paring with the Face Flat Against the Work:

Paring with the Face Flat Against the Work:

When paring, it’s typically best to use one hand to steer the blade and the other hand to push the tool into the cut. That gives you both control and power.

Scraping:

Hold the tools as shown to the left and pull toward you with firm downward pressure. Scraping is an excellent technique for cleaning up hand-cut joints, such as tenons and rabbets.

Download the free PDF:

Basic_Guide_to_Chisels

– Christopher Schwarz; Illustrations by Matt Bantly

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.