We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Working with Melamine

It’s dirt cheap, it’s practical, and best of all, there’s no sanding and finishing!

by Dave Munkittrick

Melamine is the professional cabinetmaker’s best friend. Build a cabinet with it and you have a complete, durable interior that requires no sanding (yes!) and no finishing (oh, yeah!). Pros often build whole kitchens out of melamine and then dress the boxes with plywood end panels and solid-wood fronts. The bright melamine cabinet interiors are easy to search, stain resistant and tough as nails. Entertainment centers and home office, laundry-room or mudroom cabinets are also made with melamine. Most home centers carry melamine shelving with the edge banding already on. Just buy or make shelf supports and you’re in business.

Melamine has found a home in many a woodshop. The durable, slick surface is perfect for jigs, fences, outfeed tables and router tables. I use it in my shop as an assembly table cover. Glue drips pop right off and the slick surface makes it easy to slide around heavy assemblies. It’s not as durable as plastic laminate for high-wear surfaces such as countertop and desktops, but it’s plenty tough for shop use.

Still not sold on melamine? How about saving money? It’s about half the cost of birch plywood. Not only that, but you get better yield from a sheet of melamine than from veneer sheet stock. That’s because you don’t have to worry about grain direction. Better yield at a lower cost—you save both ways.

Here are some tips on how to make this staple material of the modern cabinetmaker work perfectly for you!

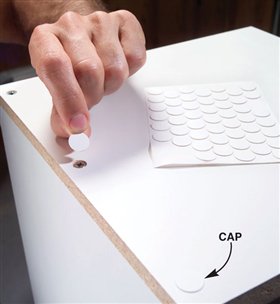

Cover Unsightly HolesThe easiest way to cover exposed screw heads is with Fast Cap self-stick caps. These discs come in typical melamine colors and they’re a cinch to apply–just peel and stick. |

|

Flush-Fit Caps Appear InvisibleA flush-fit screw cap looks a whole lot better than the surface-applied caps. Plus, they are less prone to getting knocked off. The FlushMount carbide drill bit cuts a shallow 9/16-in.-dia. countersink for the self-stick cap. An adjustable brad-point bit protruding through the center of the carbide bit drills the pilot hole. Both bits can be adjusted for depth of cut. Just drill, screw and cover. The caps are almost invisible. The same system can be used on wood-veneered sheet stock. |

|

Repair, Don’t DespairSmall nicks and gouges are easy to fix using SeamFil. It works just like wood filler but it’s designed for plastic. Just work a little into the wound and scrape it flush using a putty knife. After the filler dries, use a utility razor to remove any excess. It makes a quick, easy repair that’s only noticeable at close range. Sources(Note: Source information may have changed since the original publication date.) All Safety Equipment & Supplies, AllSafetySupplies.com, 888-739-1080, Kevlar gloves, #SS-GLK600PD2, $5. Woodworker’s Supply, woodworker.com, 800-645-9292, Freud LU97 double-sided laminate blade, #117-386, $90. MLCS, mlcswoodworking.com, 800-533-9298, 1/4-in. spiral down-cut bit, # 5177, $14. Woodworker’s Hardware, wwhardware.com, 800-383-0130, 8 oz. RooClear melamine glue, #R8012, $4; 16 oz. Titebond Melamine Glue, #F4014, $7; 50-ft. roll of white 15/16-in. self-stick tape, #FCFESP 1516 50WH, $14; Double-sided hand edge trimmer, #VIAU 93, $13; SeamFil, 1-oz. squeeze tube: white #K901, black #K914, almond #K941, $4 ea. McFeely’s, mcfeelys.com, 800-443-7937, 52 white PVC peel and stick caps, #FCS-6100, $2; FlushMount carbide drill bit, #FCS-6050, $40; 52 white PVC peel and stick caps, #FCS-6100, $2. This story originally appeared in American Woodworker September 2004, issue #109. |

|

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.