We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Shop-necessary protection gear. Standard safety gear and practices not only help keep you safer in the shop, they could well improve the quality of your work.

Seasoned professionals also benefit from woodworking safety.

Regardless of your experience level, it never hurts to review the basics. In fact, I believe there are a number of standard safety items and practices that not only help keep you safer in the shop, but also could very well improve the quality of your work.

Personal Protective Equipment

Personal protective equipment, more of a category than one specific item, is one of the most basic and fundamental things you can do to be safer in the shop. Protect your eyes, ears, and lungs whenever possible. I wear my protective lenses nearly 100 percent of the time I am in the shop. Keep a pair at every machine so eye protection is never more than an arm’s length away.

For the ears, I prefer headphone-style protection. My headphones have Bluetooth so I can listen on the go while working. If you are a fan of podcasts, this is a major plus! But keep in mind that if you listen to music, you’ll hear almost nothing of the outside world. This could be hazardous around tools where the sound of a motor or cutting edge serves as an early warning of potential problems. Turn off the music to make cuts.

To protect your lungs, rely on a half-mask respirator. I recommend you stick with one of the bigger names, such as 3M, as it is much easier to find replacement parts and filters. Also, it’s important to make sure a respirator fits your face. If the mask does not fit properly, it won’t suitably filter the air. And, if you are wearing safety glasses, you’ll want to invest in a respirator with a down-firing exhaust vent to prevent lens fogging.

Dust Collection

Not just for large machines. Dedicated dust collection for portable power tools should not be a luxury item.

Personal protective equipment does a fine job of protecting us from dangerous elements in our shop, but dust is one of those things that we should prevent earlier in the process. Instead of blocking the dust just inches from our faces, why not collect it at the source? This is where good-quality dust collection comes into play. Most modern power tools come with some form of a dust port. With the growing public consciousness about the dangers of wood dust, it’s clear that manufacturers see the writing on the wall.

Dust collection is quickly becoming a feature that is valued nearly as much as horsepower. There are two types of dust collection that you should be concerned with. One is for the big power tools. These tools generally take 4″ connections and require a lot of air movement. Full-size dust collectors and cyclones provide that amount of movement. And if you plan on running ductwork in your shop, you really need some serious air movement to effectively remove the smallest and most dangerous dust particles.

For portable power tools, you want something like a dust vacuum or a dedicated dust-extraction unit. Dedicated systems, while significantly more expensive, are a great investment as they are built to withstand long run-times and gather fine dust.

Push Sticks/Paddles

Always a better choice. Push sticks are effective and come in a variety of different designs to keep your fingers away from danger.

So what’s the best way to keep from getting cut by blades and bits? (And don’t answer, “Have someone else do it!”) One way is to increase the distance between our bodies and the cutting edge. Instead of pushing wood through our machines with our bare hands, the use of push sticks and paddles can enlarge our “safe zone.” This way if disaster does strike, it is unlikely that your fingers or hands will be pulled into the action. I rarely operate tools such as my table saw, jointer or router table without a set of paddles or a push stick in my hand.

Featherboards

Performs half the task. All stock should be held flat to the saw and tight to the fence as you cut. A featherboard takes your guide hand out of the picture.

Much of “safe woodworking” comes from keeping the workpiece secure and moving it deliberately in the proper direction. But by design, our blades and bits are usually pushing against us. This is where featherboards are worth their weight in gold.

Trying to push a long board through the table saw can be incredibly tricky, simply because you absolutely must push forward and into the fence at the same time. But with the aid of a featherboard, you really only need to be concerned about pushing the board forward. This type of controlled cut not only yields better results but goes a long way in helping to prevent kickback.

Featherboards come in all shapes and sizes. And they’re easy to make. Many commercially available models are magnetic and can be modified to work as hold-downs to make your cuts safer and kickback less of a possibility.

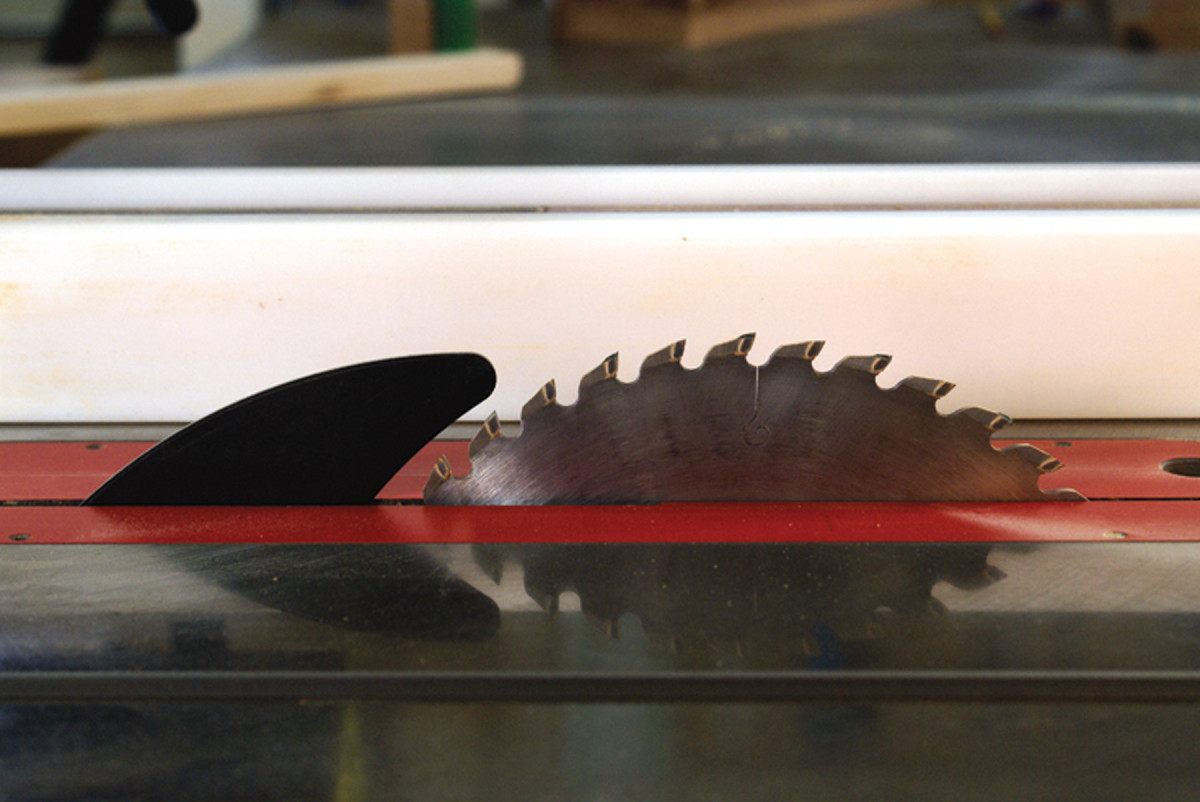

Splitters

Keep wood apart. Kickback is a hazard many woodworkers experience. A splitter or riving knife (shown here) is a safety item that reduces potential problems.

The most effective device to prevent kickback is a splitter or riving knife – a thin piece of wood, metal or plastic positioned behind the table saw blade in such a way to prevent wood from contacting the back of the blade, where kickback originates.

The sad truth is that most folks remove the safety gear from their saws. At least part of the blame for this trend lies on the shoulders of saw manufacturers that have made little effort to incorporate splitters and guard assemblies as user-friendly features to their saws. But with changes in Underwriters Laboratories guidelines and a clear change in public sentiment, saws are now being manufactured with riving knives that are easy to remove and replace when necessary. It’s about time!

Now if you’re one of those folks whose splitter/guard assembly is gathering dust in the corner, please do yourself a favor. Pick up an aftermarket splitter and install it. It is worth your time and effort. And I must say, after years of using a splitter on my table saw, running it without a splitter feels as unnatural as driving my car without a seatbelt.

Knowing how to protect yourself in the workshop is not something you can learn overnight, or even during Safety Week. It’s a bank of knowledge and experience that’s developed and honed over time. We only have one set of lungs, one set of eyes and one set of hands. These are the most important, valuable and irreplaceable tools in our shops. So, much like any other prized tool, let’s use them properly, protect them and keep them in top condition.

Editor’s note: this article is adapted from “The Wood Whisperer: Not Just for the New,” which appeared in the June 2009 issue of Popular Woodworking.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.