We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Any experience making or repairing chairs gives you a little bit of insight into how important the joinery is in chairs. And chairmakers have long used socket joints – joints made with a round hole and a round tenon – because they can be made quickly and easily. One problem: these are a rather weak type of joint. That explains why with so many chairs when the glue fails, the socket joint fails and you end up with a loose, wobbly chair (or worse).

Any experience making or repairing chairs gives you a little bit of insight into how important the joinery is in chairs. And chairmakers have long used socket joints – joints made with a round hole and a round tenon – because they can be made quickly and easily. One problem: these are a rather weak type of joint. That explains why with so many chairs when the glue fails, the socket joint fails and you end up with a loose, wobbly chair (or worse).

An examination of Windsor chairs offers insight into overcoming this problem of socket joints. As chair making expert and “Make a Windsor Chair” author Mike Dunbar points out:

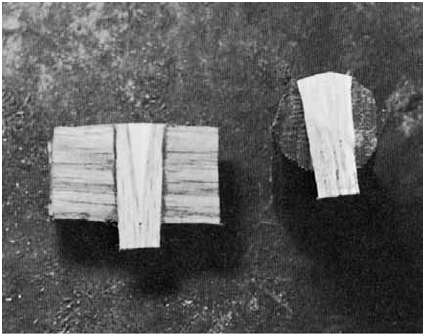

“Every joint in a handmade Windsor chair incorporates some mechanical feature that holds the join together after the glue has failed . . . the ways Windsor chair makers overcame socket construction’s inherent weakness are truly remarkable.”

The solutions you can find examining Windsor chair joinery include straight wedged joints, locking taper joints, drive fit tenons and tenons in compression. To learn how these types of socket joints work, download this free except from Dunbar’s fascinating book on the subject:

“Make a Windsor Chair” by Mike Dunbar is included The Chairmaking Ultimate Collection (which features four books, two DVDs, and eight digital videos). Available now at ShopWoodworking.com!

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.