We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

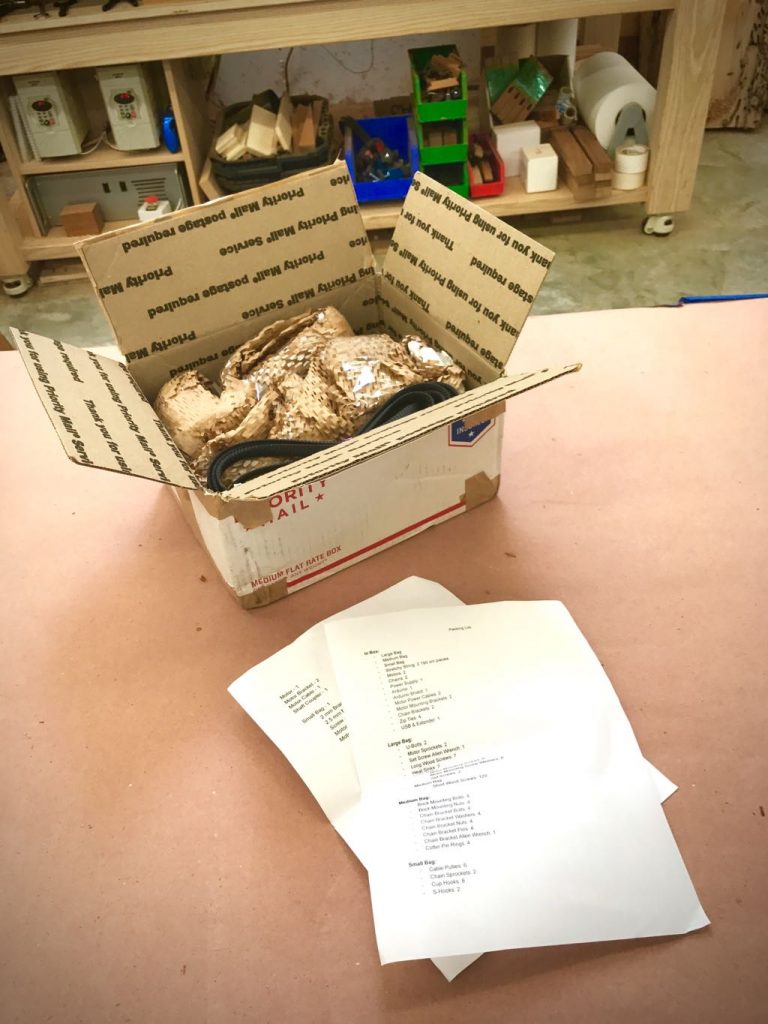

Good things come in small packages. There’s a CNC kit in this box

Several weeks back I reported on the Maslow CNC that costs just $500. Here’s Part One and Part Two if you missed it. This is a Kickstarter project, which means that it’s a crowd-funded product still in its development phase. Being a backer means you’re not so much a buyer as an investor enticed by the opportunity to get in early at a lower price before it’s released to the general public. And, as with all crowd-funded projects, there’s some risk on the backer’s part. Fortunately, the Maslow team has been through this before and know what it takes to complete a project like this. A lot of progress has been made toward their June date to ship final kits to their supporters.

Early beta kit of the Maslow $500 CNC. Just a parts list at this point. Instructions and files are online for beta testers to refine.

The Maslow is a CNC kit to which you add a few 2x4s, some plywood and bricks. Seriously. You need two old fashioned bricks to complete the kit. The result is a vertical 4′ x 8′ CNC that can work on full sheets of plywood. Yeah. That’s a lot to take in. The idea of a $500 CNC certainly caught the attention of the online world and the campaign raised more than $300,000 with more than 1,200 backers all over the world who are anxiously awaiting their Maslow kits.

In scale. Here’s the Maslow CNC kit sitting on the bed of my 3′ x 6′ dual spindle CNC. Hard to believe that there’s a 4′ x 8′ CNC kit inside.

Anyway, Bar Smith, Hannah Teagle, Tom Beckett and the Maslow gang have been very busy since the campaign ended in late November. Taking on a complicated project — especially one that’s grown in scale and gone viral all over the internet is quite a challenge. Because they’re nearby I’ve been keeping in touch and am happy to report that it looks like the Maslow CNC team has been making serious progress. So, it’s time for a quick update.

Over the last week or so, Maslow started mailing out a beta version of the CNC kits to a group of 100 backers who’s job is to give valuable feedback, suggest final improvements, etc., before the final kits ship to those 1,200 anxious backers in a few months – and I’m a beta tester. My kit arrived today in a standard U.S. Post office medium flat rate box that measures just 9″ x 11″ x 6″. Yes, the entire Maslow CNC kit fits in that little box.

All those parts in that little box. And, this is the deluxe kit, too. In the lower left- hand corner, there’s an extra motor, brackets and other parts so that this Maslow is capable of vertical Z-axis control to adjust the depth of cut.

As you can see from the photos, there’s quite a bit of work to be done, and lumber and plywood needed, before this little kit becomes a real working CNC. As I’ve said in previous posts, the Maslow CNC is not the same as serious, heavy-duty CNC nor is it expected to be. Keep in mind that it’s a simple CNC in kit form. It’s designed to cut parts out of plywood or other flat materials. Though you might not be using it for heavy duty CNC duties, it might just work out in a woodworking hobbyist’s shop for digital woodworking tasks like cutting patterns, for example, or for other projects from readily available downloadable plans. For those who missed the Kickstarter campaign, and are interested, new orders will be taken for Maslow CNC kits in about a month.

Over the next few weeks, between furniture orders and other projects, I’ll be assembling the kit, building the CNC’s frame and testing the machine in its early form. Also, two good friends who are skilled furniture makers and regular CNC users — Bob Spangler and Curtis Erpelding – will be taking the Maslow into their own shops for testing and feedback. Since all three of us saw the prototype last fall we’ve been looking forward to giving it a try. More to come over the next few weeks.

To see the entire series on the Maslow CNC click here.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

That is truly an amazing design leap they’ve made. Gotta love a CNC whose parts list includes “two bricks” 🙂