We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Q. I think predrilling screw holes is a real drag, so I rarely do it. Most screws seem to work fine without all that bother. Why are you always advocating predrilling?

Q. I think predrilling screw holes is a real drag, so I rarely do it. Most screws seem to work fine without all that bother. Why are you always advocating predrilling?

A. Call us old fashioned, but when you’re working in solid wood, we believe you’ll get the most effective and longest-lasting fastening power from screws when you drill correctly sized clearance and pilot holes.

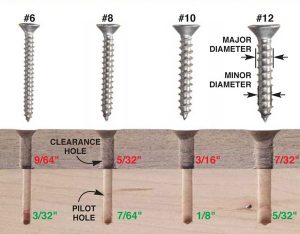

First, drill a pilot hole through both boards. Pilot holes guarantee that your screw won’t break off and your wood won’t crack. For most hardwoods, the pilot hole should be at least as large as the screw’s minor diameter. If the screw has deep threads, or the wood is very hard, the pilot hole should be another 1/64-in. larger than the minor diameter. For softer woods, the pilot hole can be 1/64-in. smaller.

Skipping the pilot hole, or drilling one too small, can create hairline cracks in solid wood and MDF. Visible cracks are obviously bad,but other cracks that are too small to see can eventually widen and cause the joint to fail.

Second, enlarge the pilot hole in the top board to make a clearance hole. This larger hole allows the screw to pull the two boards together. The clearance hole should be at least as large as the major diameter of the screw. Skipping the clearance-hole step often results in a small gap between the two boards you’re joining together. Glue won’t effectively bridge a gap larger than the thickness of a piece of paper.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

I am a novice, but it seems like predrilling in home construction, with 2×4’s and 1×2’s is unnecessary and will actually weaken the screw’s holding power. Without predrilling, the wood squeezes the screw for a better grip. Maybe this article only applies to thin or hard types of wood. Has anybody done any tests to compare the ‘pull out strength’ of predrilled vs undrilled screws? If cracking the wood is a concern, then predrilling would be recommended for nails too.

The article is correct, regardless of screw quality.

This information is available in all reputable texts. For instance Ernest Joyce has a good section on screw fixings

A screw cannot perform its function of drawing the two parts together without the clearance hole. Building sit practice is not the best!

The editors answer fails to mention that screws generally follow the path of least resistance, so pre-drilling ensures that the screw will not wander from its intended path. A hinge screw driven at an angle can cause problems with the proper closing of a hinge, especially on small hinges found on jewelry boxes and the like.

If you are driving screws with brute force into solid wood using an 12V+ electric drill, drill point screws are a great options. However, the material cut by these screws remains compacted in the thread area of the hole, which can weaken to grip of the threads. If you drive enough screws that may not matter. But even these screws are problematic if you are driving into the edge of plywood.

Hand tool woodworkers will want the loose material removed by pre-drilling for easier driving and the better grip leads to the possibility of needing fewer screws. On small boxes cracking the wood is much more likely because the stock thickness is often less than 1/2 inch, so pre-drilling is necessary.

I also concur with this info. on proper hole preparation for screwing regular wood or drywall type screws into wood. Although there are a No. of Co’s now that manufacture screws with a drill point on them rendering a predrilled hole unnecessary. I’m a cabinet maker and I use screws like this from The Quick Screw Co. You can usually even drive their screws very close to the end edge of a board without it splitting. Another screw that is very good at this are the Spax screws, which are available in limited sizes and lengths at Home Depot. I’ve driven these screws in the end grain of Hard Maple without them breaking or the wood splitting. In fact since I’ve discovered these I no longer use regular zinc lag bolts on larger projects, since the Spax bolts are also hardened and won’t break under heavy usage, and are only slightly more expensive. Another good source of quailty screws in many sizes , lengths and types is Mc Feely’s.

I can not completely agree with this article. If you use high quality screws with a partial thread the pre-drilling is not neccessary. If you use onyl cheap drywall-screws then yes.