We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

In preparation for this series of articles, I’ve been upgrading my digital calipers. These Clockwise digital calipers are some of my favorites. Shown are the 12″ and 6″ digital caliper. Smooth, accurate and with a big screen, they are easily read at a glance. They read in decimal inches, millimeters, and fractions of an inch. The 6″ version is just over $20 and is excellent.

In part one we introduced tools for standardization. These are the measuring tools that you also use to verify and quality your other tools. Every woodworker should have a high-quality combination square at the very least. In part two, I covered basic measuring tools: rules, tapes, and squares. Certainly, these are the tools that get the biggest work out in woodworkers’ shops. And, now it’s time to dial it up a notch and cover tools for precision.

What are tools for precision and why do we need them?

In this category, we’re including calipers, micrometers and other testing equipment such as dial indicators. These are the tools that measure the thousands of an inch and up. Why would a woodworker need a precision tool for this level? The rule of thumb for engineers and machinists is that your testing and measuring instruments should be 10 times more precise than the smallest increment needed in your work. Outside of joinery, which needs a high level of precision, furniture makers should strive to work at an accuracy of 1/64” or better. Translated to fractions that would be .0156”. So, following the rule of thumb of a measuring tool being 10 times the needed measurement, it would be nice to be able to measure to .001” to .002”. Even if you decide that 1/32” is good enough that’s .032” that means a measuring goal of .003”.

Sometimes you learn slowly from your mistakes — particularly if you’re in a hurry building furniture at a frantic pace. I’ve gone through a least a dozen of these cheap digital calipers in the last decade. They die early and eat batteries like crazy but are accurate enough for hybrid woodworking. Learn from my mistakes. Better to buy quality calipers you can use for a long time.

Where do measurements of this accuracy count for woodworkers?

Milling wood to thickness and joinery tolerances is first on my list. In my work, final thickness matters as it’s tied into joint making. No matter what method you use to produce your joinery, you’re going to make to measure the joint or joint position with some kind of reference position on the side or the center of the board. If your board thicknesses are not precise from one board to another, your joint will move. For years, I tried to get my board thicknesses accurate to .010. Since I’ve added digital tools like CNCs to my shop, I aim for .001″ – .003″ accuracy.

I’ve also found that the difference between a tight and loose joint could be in the range of .003”-.030”. On top of that, during joint making, you have to measure tenons and shoulders precisely. Small inlays need to be as tight as .002” or so. And, all of this is before you take into consideration the higher precision needs of digital woodworking tools, such as a CNC.

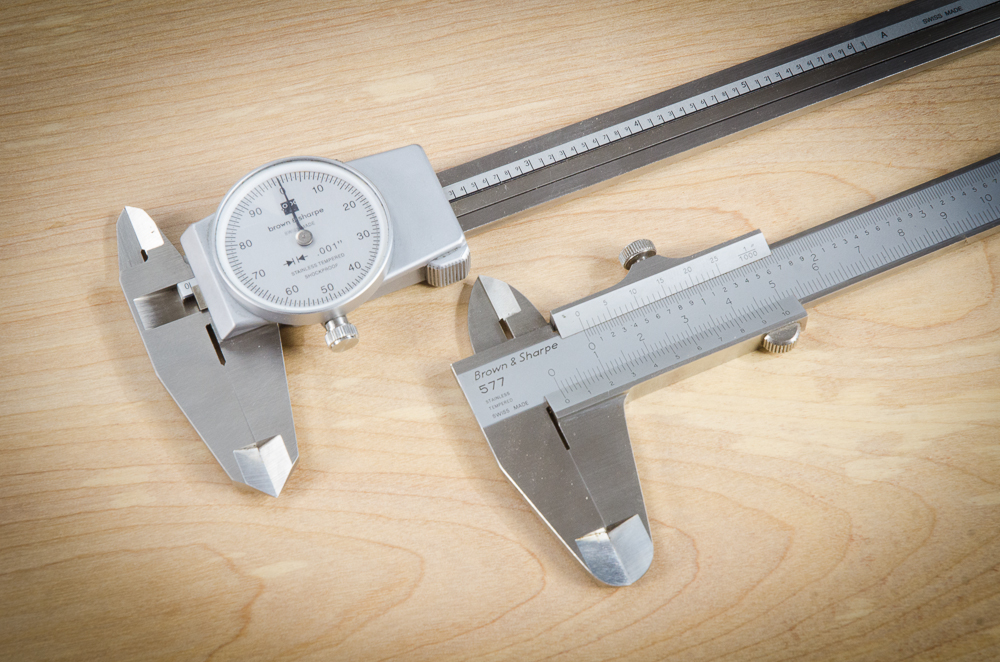

Along with Mitutoyo, these Swiss-made Brown and Sharpe dial calipers are as good as it gets when it comes to analog instruments. The machining is exquisite and they move smoother than any caliper I’ve seen. The Brown and Sharpe vernier caliper at the bottom is at least as precise but more awkward to use.

Dial and digital calipers

As a practical matter, the tool for measuring this kind of accuracy is a caliper. These are usually found in three forms: a dial caliper, a digital readout caliper, and the traditional vernier caliper. They come in sizes from 4” to 12” and way beyond. The most common and useful size is 6”. Starting from the last, the vernier caliper works by aligning marks between the vernier scales on the body and extension of the caliper. Once you the find two lines that align, you add that fraction to what you already know. I have a very nice Brown and Sharpe vernier caliper that’s incredibly well made. But, I’ll be the first to tell you that you better get a strong set of glasses or a magnifying glass to use one. As a result, using them is slow and inconvenient. Despite the extra effort in using them, if they’re well made, they are very, very accurate. Even with the convenience of more modern alternatives, many long-time machinists swear by them.

Out of curiosity, I purchased this plastic dial caliper from China for $5.67 including shipping. Accuracy is claimed to be .003″ – .005″. I think .010 would be about right. I like how the inner dial is in fractions of an inch which is handy for woodworkers who like to work that way.

Next up are dial calipers. With a rotary dial representing fractions of one or two full units, these are easy to use and can measure to the 1/1000”. Because the display is visual, they are particularly useful if you’re trying to compare differences between two measurements in a hurry. Your eye will quickly see changes. So, if you’re running boards through a planer, you’ll see those fractional changes by the rotation of the dial.

Inexpensive and readily available. These Husky brand digital calipers are available at local home centers. Not as accurate as well made as iGaging or Clockwise models but good enough for most woodworkers and they don’t consume batteries. They come with a bonus: a lifetime warranty. If something goes wrong, return them for a new one. One of these sits on my planer ready for duty and hasn’t used up a battery in two years.

Finally, there’s the modern version of the caliper that uses a digital display. These are very easy to use. Just look for number changes as you take measurements. Good ones easily measure accurately to 1 or 2 thousands of an inch. The best ones are accurate to .0005”.

The iGaging OriginCal digital caliper is accurate, inexpensive at $35-$45 and is an “origin” style caliper that remembers where zero is so you can take multiple measurements. Of all the calipers I tested, this was the most accurate. An alternative to the Mitutoyo Absolute Origin model. Excellent tool.

Digital calipers come in a couple of forms. Regular ones need to be pushed back to zero and reset before each measurement. The “Absolute Origin” or origin style popularized by Mitutoyo, remember their origin point and where they were last even if you turn them off. The Origin style calipers are wonderful, none that I can find offer auto shut off. So, if you leave the display on, they’ll drain the battery quickly.

Traditional and digital. These micrometers are for super accurate measuring tasks. The analog one is accurate to .0005″, the digital one shown is accurate to .00005″. Useful for measuring metal, like CNC and router bits.

Micrometers are for high precision

Now, we’re getting into accuracy levels of .0001” or better. And, a reasonable question is why would a woodworker who works in a material that expands and contracts constantly need a tool with that level of precision? For most woodworkers, the answer is you don’t need one to measure wood. I’ve had an inexpensive one in my toolbox for decades and never used it until I started using a CNC. This is a really a machinist tool used for setting up and measuring your digital woodworking tools and tooling. For example, if you’re using an accurate CNC, a micrometer is the tool you use to measure the mills and bits you use on your machines. I’ve found a lot of variations in claimed bit sizes vs measured bit sizes. If you’re doing CNC based joinery, a thousandth or three can make a big difference in the fit of your joints.

A brand new .500” bit, could be from .496” to .500”. And, once you send the bits out for sharpening, they’re always undersized so you need to measure them. Once you know the actual diameter of your bits and mills, you can put the information into your tool libraries in your CAM software.

One of the most useful precision tools you can buy. A dial indicator. Makes setting up a table saw or a planer easy. Inexpensive at $20 and up. Make sure you get a magnetic stand as it increases the use of the tool.

Tools for Tuning

One of the greatest benefits of having your own shop is you have the opportunity to set up your tools and adjust them for high levels of precision and accuracy. That may not seem like a pleasure for some, but the payback is what it’s all about. Accurate tools in a shop aren’t just a necessity nor is it just about trust. When your tools are well tuned, your woodworking more consistent, productive and fun. One of the best tools to help woodworkers setup their fixed tools, like a table saw, planers, jointers, and sanders is a dial caliper.

A dial indicator, combined with some kind of holder that fits in a miter slot is the perfect tool for setting up a table saw fence and blade. With the probe resting against one side of the blade, then slide down to the other side of the blade you can see if the saw blade is square to the table. Or, measure the distance from one side of the blade to the fence to the other side you can set up and adjust your fence. Attach a magnetic holder to the dial indicator and stick it to the fence frame and you can take micro-measurements of your fence position to fine tune a saw cut. Use a good caliper to measure test cuts and take readings off the dial caliper for tuning adjustments. The same approach works for fine tuning planer and fixed sanders like a wide belt or drum sander. Dial calipers and various holders are readily available and inexpensive and should be in the toolbox of any power tool woodworker.

In the short final installment of this series, I’ll offer suggested measuring tools for different types of woodworking and a new YouTube video on precision instruments for woodworkers.

Additional Resources

- All posts on Precision Instruments, click here

- Digital Woodworking on Instagram

- Personal Work on Instagram

- Digital Woodworking YouTube Channel

The Layout Value Pack

Digital Collection

Proper layout is essential to crisp work. This collection includes information on shop-made squares, the most accurate ways to measure using new and old tools, how to measure an ellipse and more! Don’t wait, start making you layout better with The Layout Value Pack download today!

Purchase on ShopWoodworking.com

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Fantastic information in an entertaining way! The blog gives so much insight into the subject matter that it does not only become quite easy to understand the concept but to implement it as well.