We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

It’s a shame customers don’t know as much about woodworking as woodworkers.

It’s a shame customers don’t know as much about woodworking as woodworkers.

They run their hands over your work and if it’s smooth they think it’s good – whereas you know that’s just the temporary wax on top. It shows the customer nothing about the weeks you spent oiling it daily or the high number of light coats of shellac used to create a deep and repairable finish.

Customers can also appreciate tight joinery – no gap is a key feature of quality craftsmanship.

But then we come to drawbores. Done right they create a half-moon gap. It is the bending action of the peg as it draws the shoulder of the tenon to the mortise that gives the joint its mechanical strength and durability. But that bending and tension will cause a half-moon gap on the surface. And when a potential customer points this out to you in an otherwise perfect piece, your answer that it’s a sign of quality craftsmanship, will make you sound like a used car salesperson with a box of Rice Krispies in their toolbox. (Poured into the valve train it’ll quiet noisy engines, for a while.)

To fill that gap you could use putty, thus submitting yourself to mockery from peers. You could make filler from sawdust and glue. But that never turns out well. Or you could peen the peg. Yes, peen it just as you would metal.

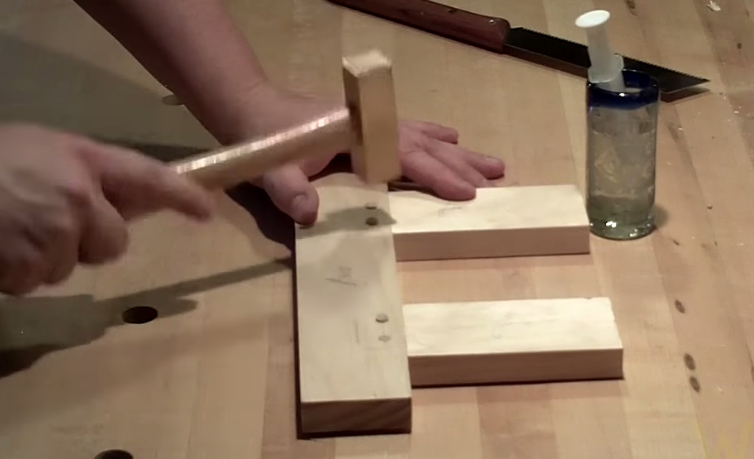

Cut the peg off proud of the face. Maybe three business cards proud. Apply a few drops of water to the end grain of the peg and let it soften up a bit. Then with a small, convex hammer tap around the edge of the peg. Keep tapping and soon the peg will round over and fill the gap at which point you can cut it flush or pare it back.

A cross section view of the gap that can be left using a drawbore.

Ta-da! No gap.

Now your piece will look like every other one that’s pegged for cosmetic reasons instead of drawbored for functionality. But at least your customers won’t notice a gap, and you’ll know it was done right.

– Shawn Graham

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

I understand the errors that are pointed out in the previous comments but hey guys, give him a break instead of nit picking. I am not an expert woodworker and I very much appreciate the technique Shawn has given us. Thank you Shawn, and keep putting yourself out there as I am sure others can benefit from your knowledge.

You seem to have a different experience than what I have had. I use a sharp brad point drill with backer board and my exterior case holes have slight to no need of filler or mushrooming the gap. I do glue the tenon with hide glue and wax the dowel after sharpening the tip before insertion. The only way that dowel is coming out is with a drift punch and a BFH with extreme prejudice. Maybe I have just been fortunate to have the right sized dowel rod.

I think you mean crescent moon, not half moon.