We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Add a new dimension to your woodworking skills.

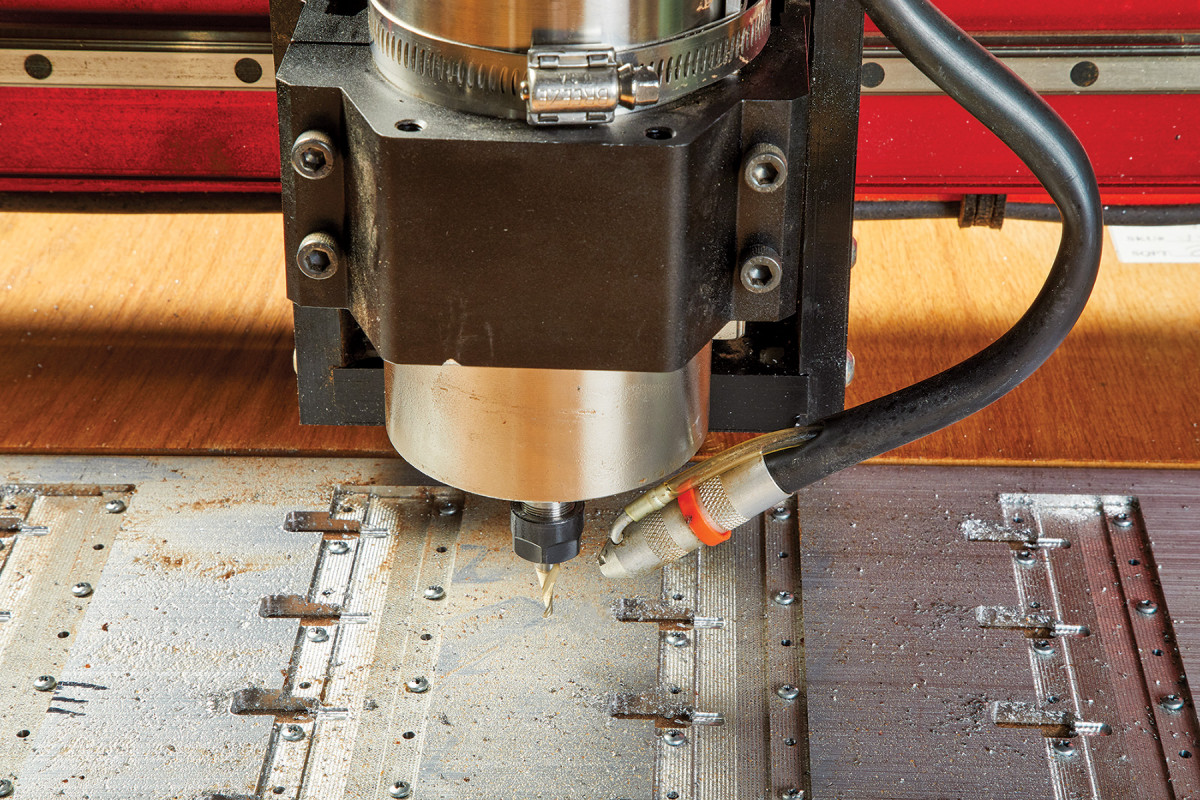

With the right techniques and tooling your CNC router can mill brass and aluminum with dependability, accuracy and consistency. Milling these materials on a home shop CNC router isn’t difficult, but milling metal requires a different and a disciplined approach. Here is a basic formula to get you started:

1. Stick with easily machinable alloys.

2. Choose the bit that is correct for brass or aluminum.

3. Mill at an RPM and feed rate that is right for your machine.

4. Use a light depth of cut.

5. Lubricate the bit.

6. Clear the chips.

The Alloys

1. 360 brass alloy material is excellent for CNC routing.

We want to choose an alloy that machines easily, is commonly available and is affordable. Aluminum alloy 6061 is a great choice to work with. Manganese and silicon are the major alloying elements. Alloy 6061 is strong, corrosion resistant, inexpensive and widely available and can be easily machined on a CNC router.

Ultra-machinable 360 brass consists of copper and zinc, and as you might guess from the name, it is made to be easily machined with the addition of lead. This attractive alloy stands up to high speed milling with minimal wear on tooling while generating chips that clear easily from the cut.

The Right Bit

2. A two-flute bit (left) for brass and single flute bit for aluminum.

The bit we’re looking for doesn’t deflect, minimizes lateral forces on your router and clears the chips quickly to give you a quality cut and long bit life. The bit that accomplishes this for both aluminum and brass is a 1/8“ diameter, 1/4“ shank spiral upcut and with a length of cut that is about 1/8“ more than your max. depth of cut, but not much more. The small diameter reduces lateral strain on your machine which increases accuracy. The 1/4“ shank and short length of cut reduces chatter and deflection while the spiral shape clears waste chips efficiently, but how many flutes? This is where brass and aluminum part ways.

Aluminum is a “gummy” metal that can cling to the cutting edge of a bit. Once that occurs, breakage is only moments away. What’s needed is a single-flute, highly polished bit that both clears chips quickly and prevents them from sticking.

360 brass is alloyed specifically to cut cleanly so a two-flute bit can be used. Two flutes offer the advantage of additional stability and more cutting efficiency.

RPM and Feed Rate

Speed and feed rate calculations give you an ideal set of numbers to cut metal. However, home shop machines suffer from a lack of rigidity. To compensate, we need to slow down the feed. I have found that a feed rate of 50 ipm at a speed of 19,500 rpm is a combination that will work well in most situations. Don’t go below this trying to baby the machine. Feed rates slower than 50 ipm cause the bit to rub needlessly increasing heat, wear and reducing its’ life. Use a light depth of cut for most brass and aluminum cutting operations with the suggested IPM and RPM

Depth of Cut

Bit deflection, backlash, and frame rigidity are enemies of a clean cut. To counter these, we need to choose an optimum depth of cut. For aluminum 6061 I have found .03“ to work well and for 360 brass .05“. It might not seem like much, but you will find your CNC router can clear a lot of metal in an hour’s time.

Lubrication

3. Just like drilling metal with a drill press, proper lubrication is key. Find something that’s inexpensive. I use “plumber’s lard.”

No doubt you have had the experience of scorching some wood while routing. The dense structure of metal creates even more heat as the bit balances between cutting and rubbing, so lubrication is critical to keeping the bit cool. A cool bit means a longer bit life and a better cut. To lubricate a cut there are several options: wax, spray can oil, or an oil mister.

If you’re cutting thin sheet stock in one pass, a wax stick makes sense. Wax sticks are less messy than oils and have the advantage of being applied once and letting you walk away. No babysitting.

For cuts requiring multiple passes, the simplest approach is to use oil from a spray can at frequent and even intervals. Avoid using sprays that are designed for stopping squeaks and breaking frozen bolts. Choose a dedicated machining oil or an oil with some cling (such as chain lube).

The best approach that guarantees constant lubrication for the bit and no babysitting of the machine is to use an oil mister. It’s an add on and uses compressed air to suction oil from a reservoir and delivers it directly to where it’s needed: the router bit. There are many specially formulated oils for machining, but in our situation the oil is not recoverable. Once it is sprayed it’s gone, so price matters. An inexpensive cutting oil that can be bought in gallon jugs goes by the name “Plumbers Lard” (not a glamorous name but it works). I also keep a spray bottle of this oil in my shop for metal drilling or CNC work when I don’t want to use the mister.

Clear the Chips

4. Chip removal helps prolong cutter life. With a big compressor, you can deliver a continuous stream of air.

You know that milling wood produces a blizzard of chips. Milling metal can do the same. Chip buildup results in re-cutting the chips, increasing heat and stress. It’s the number one cause of broken bits when milling metal.

So how do we deal with the chips? They can be blown out of the cut with an air wand or, if you have a larger compressor, set up a continuous air stream using a flexible nozzle attached to your router. (Take care to be very careful when using compressed air on metal chips, as the chips can end up in electronics, in-progress wood projects, or worse, in your eye.) A dust collector can help keep the workpiece clean, but metal chips are heavier than wood. You may need to fit a custom boot to increase air flow around the cut.

Cutting aluminum and brass with a home shop CNC router is an exciting process. By addressing the issues unique to milling aluminum and brass, you can mill with confidence. So, pick up some cutting oil and the right bits, and open the door to a new world of possibilities for your shop.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.