We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Furniture making involves making a lot of parts. Stacks of dining chair parts are made by first rough cutting stock. Then they are shaped with patterns on a shaper.

How I Make Parts Using Hybrid Woodworking Techniques

In previous posts, I wrote about what led me to get my own CNC. Now that I have one, a couple of questions come up. What’s changed in how I do my work? What do I do with a CNC? In the next two posts, I’ll explain how I previously made furniture using a combination of power and hand tools and how I’m now using a CNC to help me accomplish the same tasks.

First up. Making parts. Outside of joinery, making parts is a furniture maker’s primary woodworking task. Since my clients tend to order several pieces that means lots of parts to make. Because I make a living at it, I need to be efficient with my time and the parts I produce have to be accurate. Like many woodworkers I take a hybrid approach and use power tools where appropriate. Saws for rough cutting. Jointers and planers to square and thickness material. In the right situation, hand tools are used which often are a better, faster and more efficient solution than power tools.

Now it’s time to cut the parts that aren’t going to end up rectangular. Since I make very few things that are square that means that most parts need more work. I use various techniques to get my furniture parts into their final shape. But, my main method is using patterns and shaping.

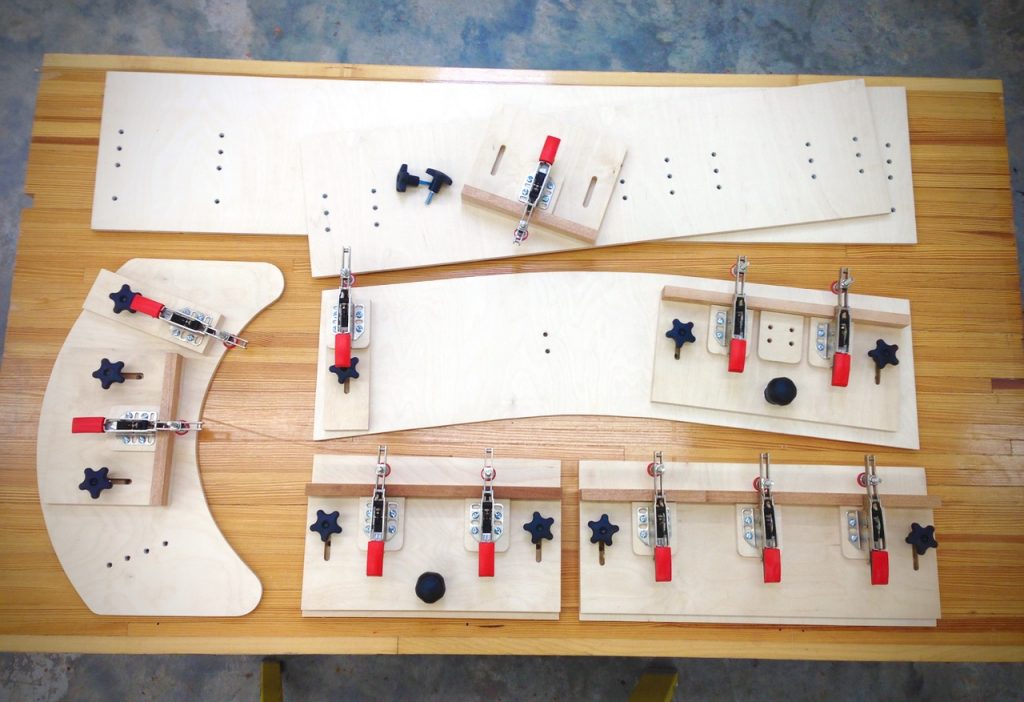

First, I rough cut the part with a bandsaw to just outside a line that is drawn around a pattern. For shaping, I use my favorite shaping jig that adapts to the part instead of the other way around. I wrote about it a few years ago for another woodworking magazine. Patterns and rough cut boards are clamped to the jig then it’s off to my two shapers to shape parts.

My shaping jig is really a jig system based on a 3 1/2″ grid layout. A standardized top clamp section is attached to various bases and adjusted to position and hold the part optimally. As a result, I can shape furniture parts of any size or shape from small to 8′ long.

Lots and Lots of Shaping

To be honest, I really like shaping. That may make me unusual. Most woodworkers don’t like doing it because it’s a justifiably intimidating process that really keeps you on your toes. However, armed with a great jig the task is faster, safer and much more pleasant to do. One of the reasons I like doing it is that when you’re done, a perfectly shaped part is the reward.

Unfortunately, shaping is not a one-step process. There’s a lot of added detail and fussiness along the way to a completed part. A key issue in using a shaper properly and safely is that excess has to be left at the entry and exit points to be later cleaned up with a small plane or a sander. After that, you sand to blend. The entire process of pattern shaping results in a very good part. It’s not a perfect part, but it’s close. And, then there’s the issue of time. Shaping is time-consuming. I regularly spend several days at a time doing it.

If it’s precision you’re after, then digital woodworking offers clear advantages when it comes to part making. Potentially, CNCs give you perfection where you need it the most. Part making is one of the best uses of a CNC router in a woodworking workshop. Because they have a high level of precision and repeatability and they don’t care if they’re cutting straight, around a curve, in a zig zag or any kind of shape you come up with, it makes CNCs an ideal tool to for cutting parts.

I’ll give you a simple example of how I use a CNC to cut a part in my next post.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.