We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Is there any advantage/disadvantage to installing a dust collector outside the shop?

It may sound as resolute as a long-range weather forecast, but yes, maybe and no. It is really a personal choice. Locating the dust collection machine outside the shop will lower sound levels and free up shop space. For some woodworkers (me included) these are the deciding advantages. But if your winters are cold, first consider how to minimize the loss of heated air, possibly through a filtered passive air return. The dust collection bucket needs to be checked frequently and emptied when full, so think carefully about logistics before locating a dust collector outside the shop proper. Be sure to plan for a way to turn the unit on and off remotely. And of course distance increases the length of ductwork, therefore airflow (CFM) may be lessened – so take that into account when sizing the unit.

What size machine should I buy?

My flippant answer is “the biggest you can,” but the better answer is to carefully analyze your shop needs and size the machine accordingly. There is really not a “magic” easy formula, but as a rough rule of thumb, try to get a machine with a no-load rated CFM about two to three times larger than that required by your biggest piece of woodworking machinery. For example, if your planer or jointer manual recommends 500 CFM, figure you will need to buy a machine “rated” at least 1000 to 1500 CFM. Several manufacturers offer design assistance and machine selection guidance.

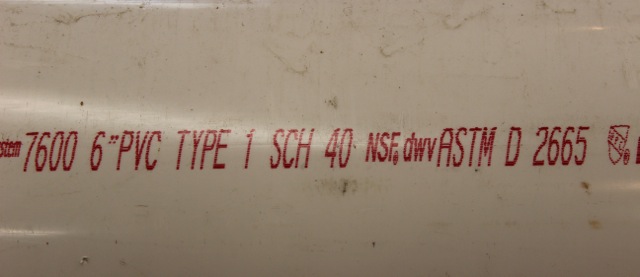

ASTM (formerly the American Society for Testing and Materials) D 2665 spells out guidelines for Schedule 40 PVC pipe such as wall thickness, minimum and maximum wall thickness, inside and outside dimensions, and pressure capacity.

What kind of PVC is best for ductwork?

Schedule 40 DWV (drain, waste, vent) PVC is the heaviest and thickest wall material commonly available, and it works great. Thinner walled pipes may work too, but because of the ready availability of Schedule 40 pipe, you may actually pay more for what should intuitively be a less expensive material. Thicker walled pipes would be overkill and unnecessarily expensive. Try to get pipe and fittings made by the same manufacturer – the fit will be perfect. Remember to bevel the ends of pipes to match the bevel inside the fitting. This is covered in the Popular Woodworking webinar “Dust Collection Ductwork.”

What size ductwork should be used?

This is the subject of considerable debate, but starting at the dust collector, run the largest pipe you can as far as you can. For example, if your dust collector has a 6-inch inlet, use 6-inch pipe and fittings as far as practical before transitioning down to match the woodworking machine’s dust port. Using a pipe larger than the inlet on the dust collector will not increase airflow.

Can metal and PVC be mixed in a dust collection system?

Some can, some cannot – but why would you want to? True, some metal tees and wyes are less expensive than PVC, but joining a PVC pipe to a metal fitting is difficult and prone to air leakage. The additional cost of a few PVC fittings will be a small part of the overall project cost and the return on investment via efficiency and ease of installation of an all-PVC network is significant.

Should PVC pipe and fittings be glued together?

I have never found it necessary. The fit between same-manufacturer pipe and fittings is so snug that only a screw or two is necessary to provide a safe and efficient connection. If the pipe and fittings are under load or stress as a result of the installation design, then by all means use glue.

What is the best hose for use with a dust collection system?

Note the smooth interior of this hose from Flexaust. The plastic is heavy, nearly clear, and extremely flexible. It also is made of a static-dissipative material.

There are hundreds of hose materials available. Variations include types of plastic, color and opacity, wall thickness, weight (gauge) of the coil support wire, flexibility and more. Because woodworkers use relatively small amounts of hose our choices are typically limited by retail availability. The best hose I ever used was transparent, heavy, smooth-walled and made of a static dissipative plastic, but it is extremely hard to source, available only in 25-foot lengths and costs about $13/foot before adding in shipping costs. Pragmatically, look for (a) hose whose coil wire is on the outside of the pipe, leaving a smooth interior that will not disrupt air flow, (b) hose flexible enough to satisfy your specific needs and (c) hose made of a heavy plastic that can withstand the rigors of daily shop use. If you can find a hose that meets these basic criteria and is also made of static dissipative material it is a real bonus.

How can I get more information about setting up a dust collection system in my shop?

Popular Woodworking offers two publications on setting up shop and dust collection. Check out “Workshop Dust Control” and “Ultimate Workshop Solutions” (for general shop projects). You will also want to download, watch and listen to the webinar I recorded. Plus, I try to answer all questions so feel free to contact me anytime or post your question here as a blog comment.

–Steve Johnson

Read more questions and answers from Steve about spark danger in your dust collection system on the Highland Woodworking blog.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Any one interested in dust collection might want to check out drop can systems and other ways of improving or maintaining the performance of their dust collector. See here:

http://www.jpthien.com/smf/index.php?board=1.0

“What kind of PVC is best for ductwork?

Schedule 40 DWV (drain, waste, vent) PVC is the heaviest and thickest wall material commonly available, and it works great. Thinner walled pipes may work too, but because of the ready availability of Schedule 40 pipe, you may actually pay more for what should intuitively be a less expensive material.”

I think you really missed the mark on this one. While I agree it may be a little harder to find, thin-walled PVC variously called “thin walled drainage,” “S&D,” “Solid Perf,” ASTM-2729, etc. it is by far a better choice. It is plenty rigid and won’t collapse, even with a DC with high static pressure. The two biggest advantages are it is much, much lighter and easier to handle, and the clincher it is much less expensive!!! The pipe may only be slightly less expensive than Sched 40, but S&D fittings typically cost of half what a Sched 40 fitting sells for- a 6″ Sched 40 wye can cost close to $40, while the same fitting in S&D (mulitple classifications- ASTM 2729, 3034 & 3035) is usually less than $20. The difference in cost can be significant for extensive or complex ductwork. The large home centers typically carry ASTM 2729 pipe in 4″ but not 6″, for that you’ll need to go to a PVC pipe or irrigation supplier. Home centers do regularly carry 4″ & 6″ ASTM 2729 fittings, however, but you’ll need to look in the drainage and irrigation area, not in the plumbing area.

I don’t know that static electricity alone could cause a clog, but perhaps it could be a contributing factor. A small accumulation of dust in a turn or bend in the system catches a slightly larger piece, that in turn catches a slight bigger piece, and so on. It is ultimately personal choice, but providing a pathway to ground for static electric charges is inexpensive, easy to do, and just “extra peace of mind.” Thanks for the great question!

Should I worry about static charge in my system? I notice that my pvc pipes develop a good amount of static after running for an hour. Could this also cause clogging or build up in the system?

Thanks!