We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

CNC "Woodturning"

By Randy Johnson

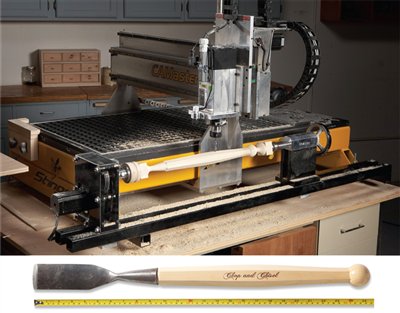

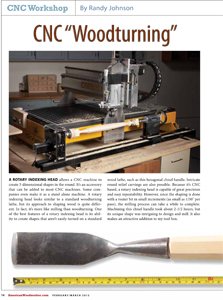

A rotary indexing head allows a CNC machine to

create 3-dimensional shapes in the round. It’s an accessory

that can be added to most CNC machines. Some companies

even make it as a stand alone machine. A rotary

indexing head looks similar to a standard woodturning

lathe, but its approach to shaping wood is quite different.

In fact, it’s more like milling than woodturning. One

of the best features of a rotary indexing head is its ability

to create shapes that aren’t easily turned on a standard

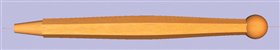

wood lathe, such as this hexagonal chisel handle. Intricate

round relief carvings are also possible. Because it’s CNC

based, a rotary indexing head is capable of great precision

and easy repeatability. However, since the shaping is done

with a router bit in small increments (as small as 1/50" per

pass), the milling process can take a while to complete.

Machining this chisel handle took about 2-1/2 hours, but

its unique shape was intriguing to design and mill. It also

makes an attractive addition to my tool box.

CLICK TO ENLARGE VIEW OF HANDLE

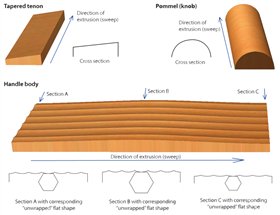

You need to think a little differently.

Think flatCNC turnings usually start out as a flat design, so the first step is to “unwrap” the cylindrical profile. CNC design software |

Click any image to view a larger version. |

Think roundThe design software converts (wraps) the flat design into its cylindrical shape to give you a preview of the final piece. |

Think partsEach part of a CNC turning is created separately. The parts are then joined to create the final design. The basic steps used to |

Basic Parts Creation

|

Each 3-dimensional part is created using a line drawing of its cross section to extrude (or “sweep”) the shape along a path. The |

|

Parting tabs are added to the ends of the final design to connect the part to the unmachined ends of the billet. The tabs are |

Basic Machine Steps

Step 1: Create a cylinder

|

Step 2:

|

Step 3:

|

Step 4:

|

Twists are also possible

|

This story originally appeared in American Woodworker February/March 2012, issue #158. |

|

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.