We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Photo by Jatin Jangid on Unsplash

There are a number of things to think about when choosing wood for your woodworking project. You can have a great design, but if the material you use in your woodworking project has flaws in it, there may be problems that cause it to break in the future. I had the opportunity to talk in detail about failed woodworking projects with Gene Wengert who is known as The Wood Doctor. With a background in custom woodworking and furniture repair, I was surprised how much I learned from the discussion. I share a few of the insights in this article, but there’s a lot of wisdom packed into this video with The Wood Doctor, so check it out.

Wood Defects That Affect Woodworking Projects

A knot is an easy defect to spot in wood, but did you know the wood around the knot can cause problems in your project? It may be ok in a table top or a panel, but on narrower pieces, the wood grain around the knot is in a different direction than the grain in the rest of the board, which can be a point of weakness. When you’re cutting out around knots, make sure you cut beyond the knot to where the grain is straight.

If you’re tempted to buy a warped board and make it flat, don’t. There is natural stress in wood and a warped board shows there is stress in the wood. If you were to mill it flat, there’s still a good chance the board will warp more in the future as the moisture content changes with humidity (aka wood movement). Be picky when you choose your boards at the lumber yard to get the best wood for your project.

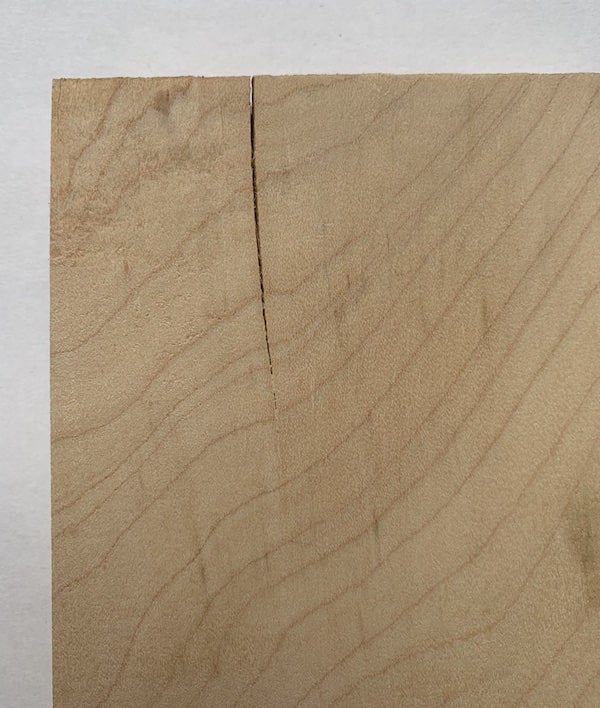

It’s not uncommon to see splits at the end of a board. If you cut off only the part that you see is split, you might be surprised when it splits further in the future. A split in wood can carry deeper into the board. You can test this by cutting off the waste you normally would to get rid of a split. Then cut off another 1/4 inch piece. Bend that 1/4 inch piece and see if it breaks where the split is. If it does, cut off more and test it again. That way you will be sure to have a strong board that won’t break with wood movement.

Type of Wood for Your Project

When I used to do custom woodworking for customers, I would often advise them against choosing to stain the wood. “If you want a dark piece of furniture, use a dark wood” I would tell them. Why? If you look at wood closely, you will see there are a variety of colors in the wood. This is part of the natural beauty. When you apply a stain to the wood, you’re disguising the natural color by applying a single color on top. Compare the walnut-stained Pine board below with the naturally finished Walnut board (right). Which one do you like better?

Depending on what you’re building, you may also need to choose a type of wood that is strong enough. For example, building the spindles on the back of a Windsor chair requires strong wood. It’s not something you can use a softwood for. Another example is building a tabletop that will wear well. Pine is a softwood so it will get damaged over time compared to Maple, which is a hardwood.

Buy Wood Dried for Woodworking

Shop at a quality supplier. That’s the short advice. Wood is a natural product and it goes through a number of processes to become lumber. If each step is not done well, it will produce lumber that could fail in woodworking projects. For example, if when a log is sawn into boards and the ends are not sealed, there will be a lot of checking (splits) that form at the end of the boards. As described earlier, these can travel deep into the wood and can cause issues.

How the wood is dried also impacts the quality of the wood. If it’s dried too much, the wood will be brittle and might fracture or chip easily. If it isn’t dried enough, it will move as it naturally shrinks. Wood moves with changes in moisture, which is a detailed discussion in the video above. If you don’t understand wood movement and the impacts of wood movement, I strongly suggest watching the video to avoid building a woodworking project that breaks after you build it.

Wood Grain Orientation

The grain patterns in wood are part of what makes the wood beautiful. If you pay attention to the grain when you’re laying out your parts, you can improve the look of your finished piece. For example, use boards with a consistent, straight grain pattern for the rails and stiles on doors. You can also use the curved grain in a board to enhance the look of a curved part in your project. Be creative with it and you will see how this can elevate your woodworking project.

I hope you’ve found this article both inspiring and educational. You will build better woodworking projects by choosing the right wood. If you want to learn woodworking skills quickly, give furniture repairs a try. It’s a hands-on way to learn how furniture is made. Watch my Fixing Furniture YouTube Channel where we’re building a supportive community about furniture repairs.

Watch more: Fixing Furniture YouTube Channel

Scott Bennett is the owner of Wooden It Be Nice, a family-owned and operated furniture repair business. He is also the creator of the Fixing Furniture YouTube channel and the Home Improvement Woodworking channel.

Scott Bennett is the owner of Wooden It Be Nice, a family-owned and operated furniture repair business. He is also the creator of the Fixing Furniture YouTube channel and the Home Improvement Woodworking channel.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.