We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

The very idea of digital woodworking is something new and strange to a lot of woodworkers, so it’s only natural there are a lot of questions. For many, the big question is “where do I start?” The answer is easy. Learn to draw using Computer Aided Drawing (CAD) drawing tools.

You don’t have to own an expensive CNC router to get the biggest benefit of going digital. You can remain a committed hand tool or hybrid tool woodworker and still greatly improve your work by simply learning and using CAD software.

Recently, I contributed an article called Digital Artistry for the upcoming December 2017 print issue of Popular Woodworking. It’s about five professional woodworkers —all with traditional woodworking backgrounds, who are now regularly using CNCs and other digital tools in their work. Bob Spangler, Curtis Erpelding, David Myka, Darrell Peart and myself. Though our work is quite different from each other, we’ve found that we have much in common through our discoveries and experiences with digital tools. For each of us, the most surprising thing is how much CAD software has had a major effect on our work.

CAD is a precision tool, the precision carries through to both the traditional and new digital methods we are using in our shops. Things fit right the first time if you start with precise drawings. No question about it: precision is addictive —we’re all hooked. But, the other big discovery is how much CAD has changed our work and affected our woodworking thinking. CAD, first and foremost, helps and even encourages you to explore new ideas. Combined with imagination, CAD opens up new pathways for creativity and encourages you to refine your designs.

Digital drawings are the ultimate “what if” tool. It’s simple to clone a drawing and try out variations and fuss over details until they’re perfected. Got an outrageous idea for a sideboard or a dining table? CAD is the perfect no-impact space to try out ideas. Who knows, that outrageous idea in the back of your head might prove to be something exceptional with a little work. With CAD you can dig in and take that next step.

Start Early

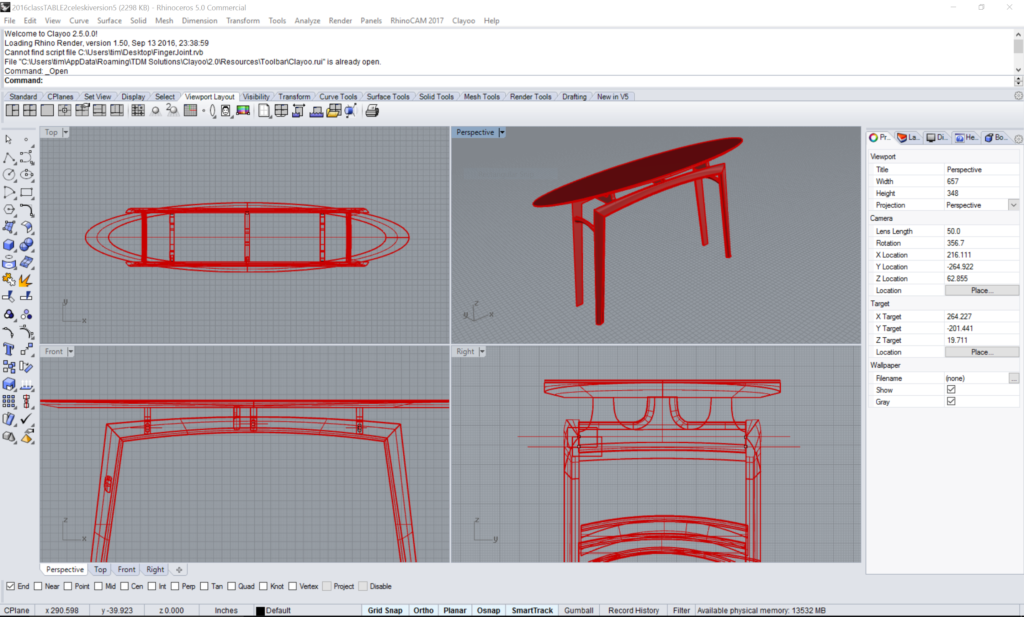

All five of us feature in my article began using CAD long before we added CNCs to our shop, so the precision and creative benefits hit us early. Like most woodworkers, we often start with a drawing pad, pencil and a simple sketch. Then our imaginations go to work. Soon, we jump into our chosen CAD software to develop a design and variations and explore and refine. Our software choices are as individual as we are. Three of us use Rhino3D CAD, two use TurboCAD but are considering moving up to more advanced 3D software.

Consider CAD

I’m a designer. Here’s an inside secret. As you develop variations on designs you create, you become a better designer. The proportions in your work improve as you see the effect of changes and how parts interact with one another. Over time, you get better. And, then there’s that added CAD benefit of precision. Even a dedicated hand tool woodworker benefits from working out ideas ahead of time and working with precise drawings.

I can offer two pieces of advice. The first is to begin using CAD right away. Do not wait. Though I’ve been using digital drawing software since the early 1980’s, I wish I’d started out a lot earlier with 3D CAD software. 3D has completely changed my work. It’s never too early to start.

Invest in Yourself

For woodworkers, the cost of CAD software is a touchy subject. Many woodworkers are tool enthusiasts. More tools and better tools are good. But, that only seems to apply to things you can touch. A fancy hand plane for $400, you bet. A set of Japanese chisels handmade by a master for $1,000 or a $5,000 table saw, no problem. But, try to convince a woodworker to invest in quality CAD software makes me feel like Sisyphus pushing that rock up a hill to only have it roll back down again. The thinking often seems to be: if you can’t touch it, cheap or free software is good enough. I got news for you: That’s a false economy. Good software is just as important as good hardware. In can be a pleasure to use, fast to learn and a powerful creative tool. That’s my second piece of advice. Don’t be cheap. With software, you’re investing in yourself. You’re investing your time. So, invest wisely.

What about cost? With decades invested in high-end design software throughout my career in design, I learned that the real cost in quality software was my commitment to learn it, not the financial costs. The financial costs were spread out over decades, and so was the vast quantities of time I put into learning to use and master it. The payback was all the things that I can create with it. I have no regrets.

Here’s the thing, like that $5000 table saw, you might find yourself using CAD software for decades. Like a good saw, good software is worth some upfront investment. Often, there’s a correlation between software costs and good technical support and solid learning tools and the time it takes to learn it. But, unlike a table saw that can be mastered in short order, learning and mastering CAD takes time. Your time.

No matter how you learn — through classes, self-paced tutorials, books or online videos, CAD takes commitment on the users part. Fortunately, most of what woodworkers need to do in CAD is basic 2D stuff, so learning to use it have to be hard. But, before you jump on the first free program you come across, look around at overhang involved in using it — support, training tools and ease of use and ask yourself: Is it worth my time? Though there are some promising ideas on the horizon for simpler to use CAD design software, we’re not there yet. It’s gong to take some commitment on the user’s part.

Back to the table saw metaphor. Using one brand of table saw is pretty much the same as using any other. But, unless you’re a career professional CAD user, CAD skills are not easily transferable between programs. That makes it better to stick with one program and committing to learning it. Do your research. Look at all aspects of owning it —learning, support, flexibility community, added tools and particularly ease of use. And, don’t forget many CAD programs come with maintenance fees. Make your choice as if you’re making a long-term investment. Because in many ways you really are.

So, there you have it. Take it from five professional woodworkers. Do you want to make great stuff? CAD will help you achieve that goal. On this point, we all agree: CAD is the secret sauce that can make your work better.

Bonus: With CAD drawings in hand, someone can run out patterns or parts for you giving you one of the best benefits of a CNC without having to own one. That alone makes CAD a real bargain.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.