We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Ipe – Wood or Metal?

By Tom Caspar

Ipe (pronounced E-pay) is a South American wood as exotic as its name. When you hold a piece, you know it’s something special. Ipe sinks in water like cast iron, is hard as nails and polishes like brass. Of course, you don’t really have to weld it, but working with ipe may make you question your sanity. Is it wood or metal?

For an exotic wood, it’s not terribly expensive. A 1-in.-thick board typically costs about $6 per board foot.

You can buy ipe almost anywhere in the United States, but most woodworkers have never heard of it. Ipe is used for decks and outdoor structures because it’s extremely rot-resistant, dries without warping, is free of knots and won’t wear out. It’s available in standard dimensions, such as 1×6 and 2×4. Deck offcuts are a blast to experiment with.

Ipe is marketed under a number of names. Dealers call it Ironwood, Diamond Deck, Pau Lope and Tiger Deck. It’s sold as Brazilian walnut in the interior flooring business.

Use it inside or outIpe can be used for indoor or outdoor furniture. It’s so heavy that this deck chair will never blow over in the wind! Ipe is useful around the shop, too, because it’s so hard and strong. An ipe carver’s mallet lasts a lifetime. Ipe drawer runners never wear out. Best of all, an ipe workbench is downright awesome. Talk about sturdy! |

Wait ’til it’s dryIpe isn’t dried for interior use. The moisture content (MC) of ipe decking boards is fairly high, about 17 percent. This MC is appropriate for outdoor furniture, but higher than the 12 percent MC of air-dried hardwoods destined for indoor use. It’s easy to air-dry ipe yourself by stacking it indoors. Monitor its MC with a moisture meter. (To get a correct reading, adjust for ipe’s high specific gravity: 0.92.) |

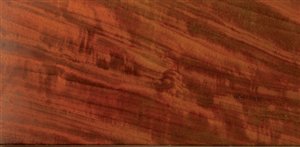

Dig for beautiful boardsSome ipe boards are absolutely stunning. You’ll find a wide variety of color and figure in a random pile of ipe, so good boards are worth digging for. Ipe’s color ranges from olive green to chocolate brown. Check out the unusual internal structure called interlocked grain in the board above. Here, the slope of the grain alternates direction every few growing seasons. This is a spectacular example of grain that’s both curly and interlocked. Pencil-stripe interlocked grain is more common in ipe. |

|

This is strong wood!Every which way you look at it, ipe is an extreme wood. It’s about 70 percent stiffer than hard maple. Outdoor furniture made from cedar, redwood and treated pine must have thick parts for strength, but ipe furniture can have the thin lines of metalwork. So be daring! The slender legs on this patio table are only 7/8 in. square. |

It’s one tough cookieGo ahead: Bang on it. Ipe is two to three times as hard as white oak. A good portion of the Atlantic City boardwalk has been replaced with ipe. Twenty years later, it hardly shows any signs of wear. |

Ipe sinks in waterIpe is incredibly dense. When you pick up a piece, you’d swear it was a hunk of metal. Ipe weighs 69 to 80 lbs./ft.3 (compare that to red oak at 43 lbs./ft.3) That’s right up there near ultradense exotics, such as ebony and lignum vitae. The darkest ipe boards are the heaviest ones. |

Seal the endsSeal the end grain of freshly cut ipe to prevent the ends from checking. (Checks are small cracks that run from 1/32 in. to 1/4 in. deep.) Deck builders brush on a special wax emulsion. It turns clear a few minutes after it dries. The surface of ipe boards may have a lot of small checks, but the checks actually close up as the wood continues to dry—weird. |

Use carbide toolingIpe is murder on ordinary carbon-steel blades. Use a carbide blade in a tablesaw and carbide bits in a router. Carbide blades are available for bandsaws. Carbide isn’t an option on most jointers or planers. Take light cuts if you absolutely must. Edges are best smoothed with a file, like brass. The surfacing machine that works best with ipe is a drum sander. Ipe dust may make your skin itch and eyes water. Use dust collection on your tools and wear a dust mask. |

Joints & glueScrews and plugs are a fast, easy way to join ipe. Ipe’s end grain holds screws well, unlike softer outdoor woods, but you must predrill pilot holes. Use stainless-steel screws with long, deep threads. Make your own plugs for an invisible joint that looks like welded metal. I bought the legs for my table, rather than turn them myself. It isn’t as much fun, but it is much quicker. Here are three legs I considered. They’re all made from solid 2-3/4-in. stock, with no glue lines, and are sanded ready to go. I chose the middle leg for my table. These suppliers make many more leg styles in various widths, lengths and wood species. |

FinishingUnfinished ipe turns silvery-gray outdoors. Apply an outdoor oil every year to keep ipe’s natural color or to protect it from stains. For indoor work, sand ipe up to 220 grit. Or go crazy: Push it to 400! Along the way, you’ll be amazed at how burnished the surface becomes—just like metal. Almost any finish will work. Floor wax preserves the color of the bizarre yellow-green streaks present in many ipe boards. These streaks are created by lapachol, a peculiar solid deposit in ipe’s pores. This story originally appeared in American Woodworker July 2004, issue #108. |

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.