We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Professional-sized ladder golf sets are larger and more robust than the chintzy ones you usually find in yard game kits. This project is a great way to use some long skinny scrap pieces too.

I love playing ladder ball (ladder toss or ladder golf in some circles) but I got sick of my cheap store-bought set constantly falling apart. Instead of buying a yet a another version, I decided to make something more durable. Of course, I couldn’t stop there, and had to add a bit of style as well, going with cherry and maple for the construction. It was a great way to spend time in the shop and create something I could use with family and friends at cookouts or camping trips. The small sacrifice in portability is well worth the final result.

Read the rules for ladder golf here

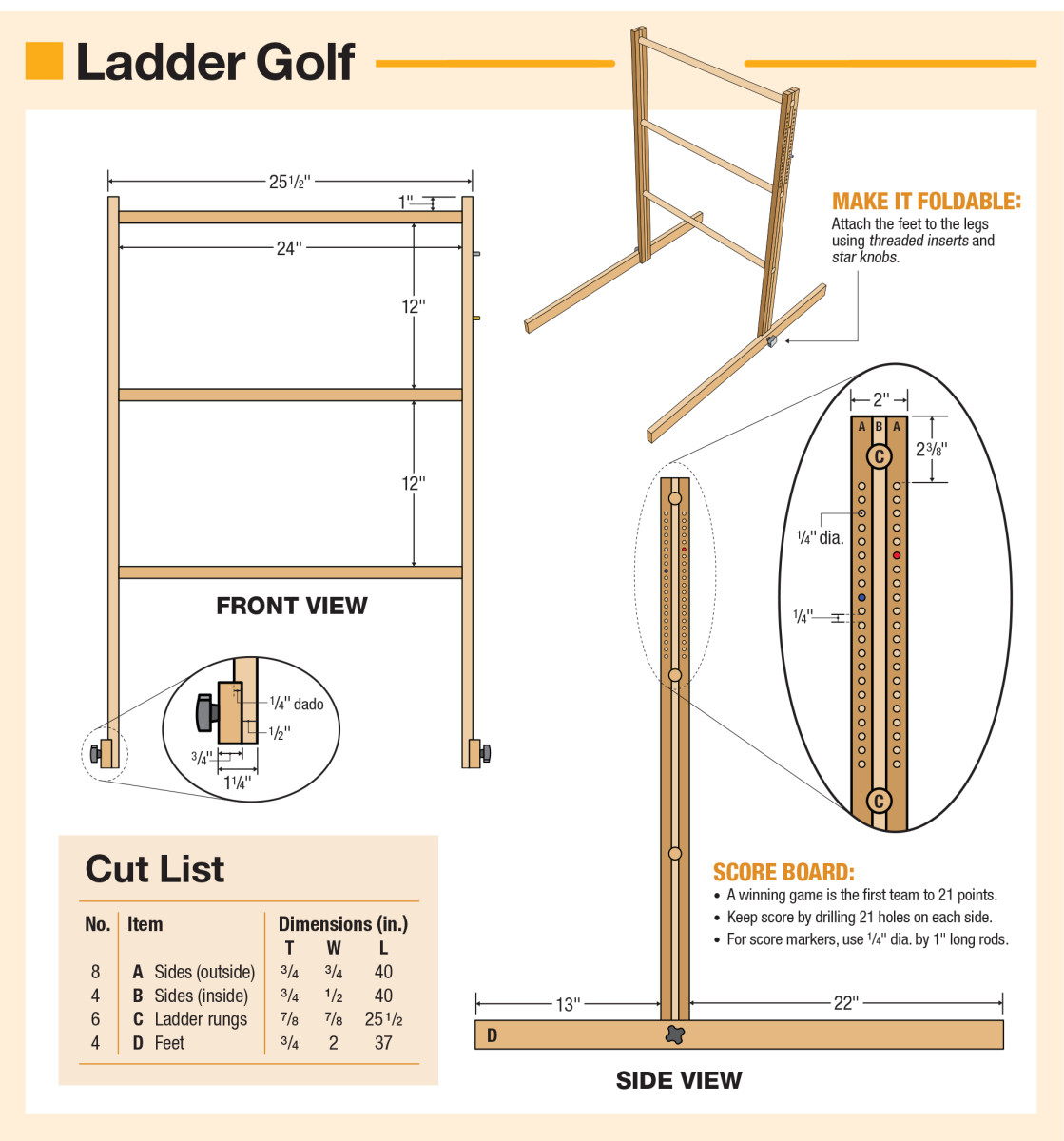

Cutlist and Diagrams

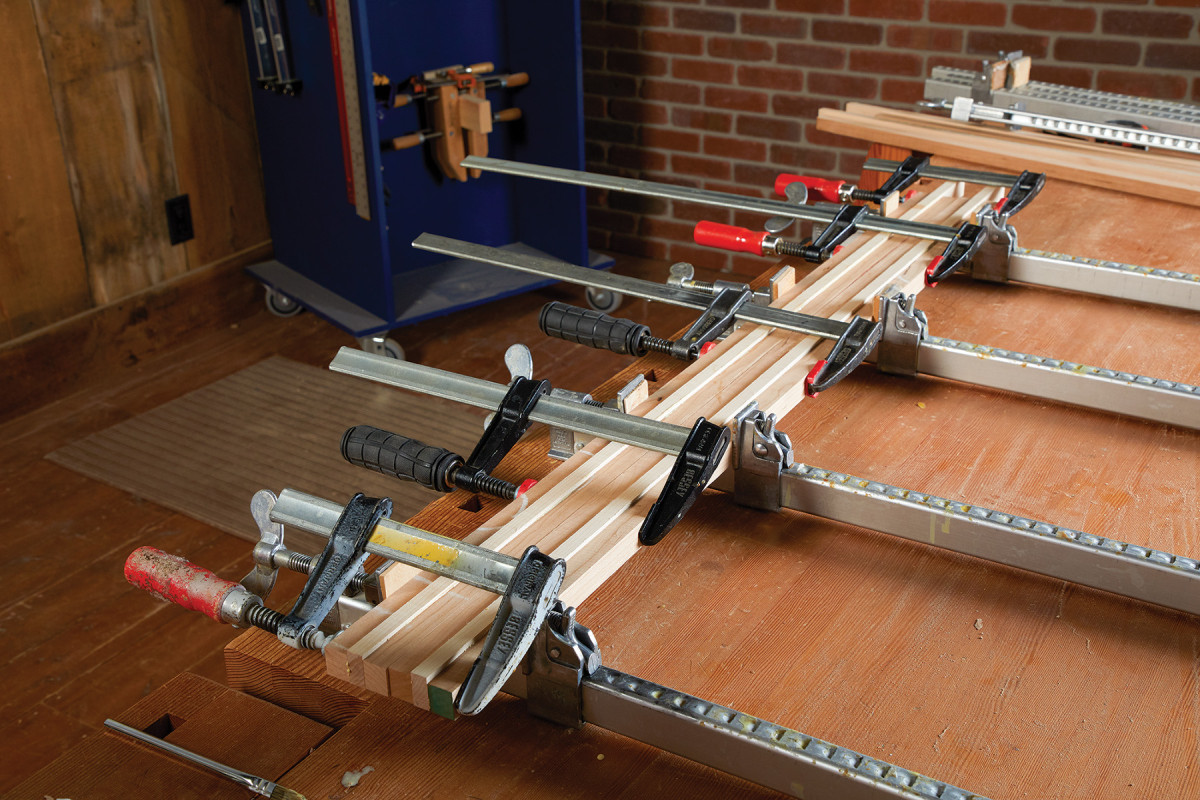

When they say you can’t have too many clamps. it’s longer glue-ups like these that they’re talking about.

Build the Sides

Plane your side boards to 7/8” thickness, then rip four 15/16” wide strips of cherry and two 1/2“ strips of maple. Edge glue the sides, sandwiching the maple between pieces of cherry, and allow to dry. Once the glue is cured, it’s back to the planer, where you can dial in the final thickness of 3/4“ thick.

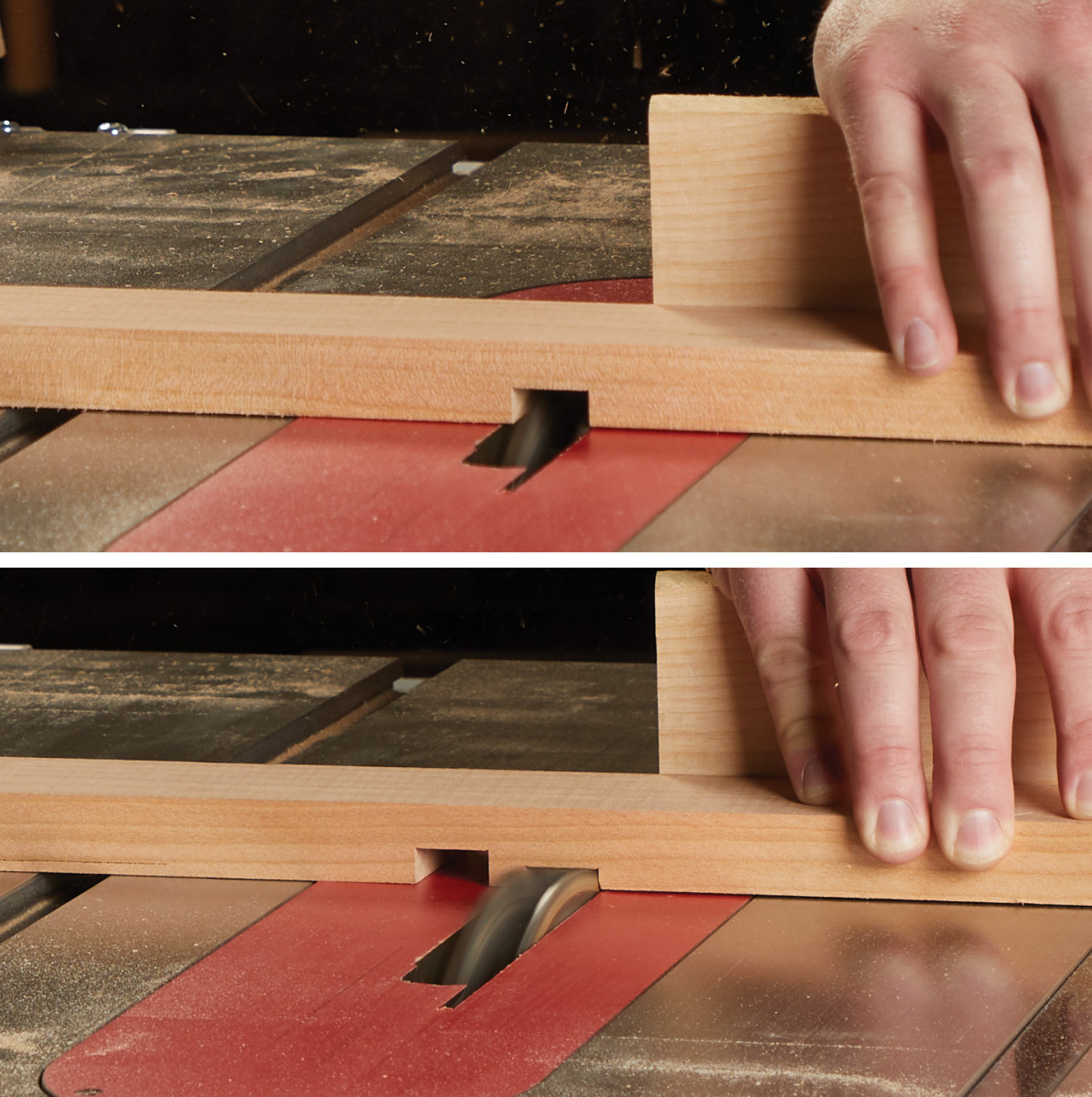

Take your time to cut the two outside edges exactly when cutting the dado for the legs.

The Legs

While you’re waiting for the glue to dry on the sides, go ahead and start on the legs. Start with 3/4“ thick lumber and trim to 37“ long. Then, install a dado stack in your table saw and set the blade height to 5/16“. Make passes on the saw until the opening is 1 7/8“ wide. You’ll want to double-check the exact measurements of your side pieces for a nice tight fit.

With the width accurately defined, clearing out the middle is a breeze.

The Dowels

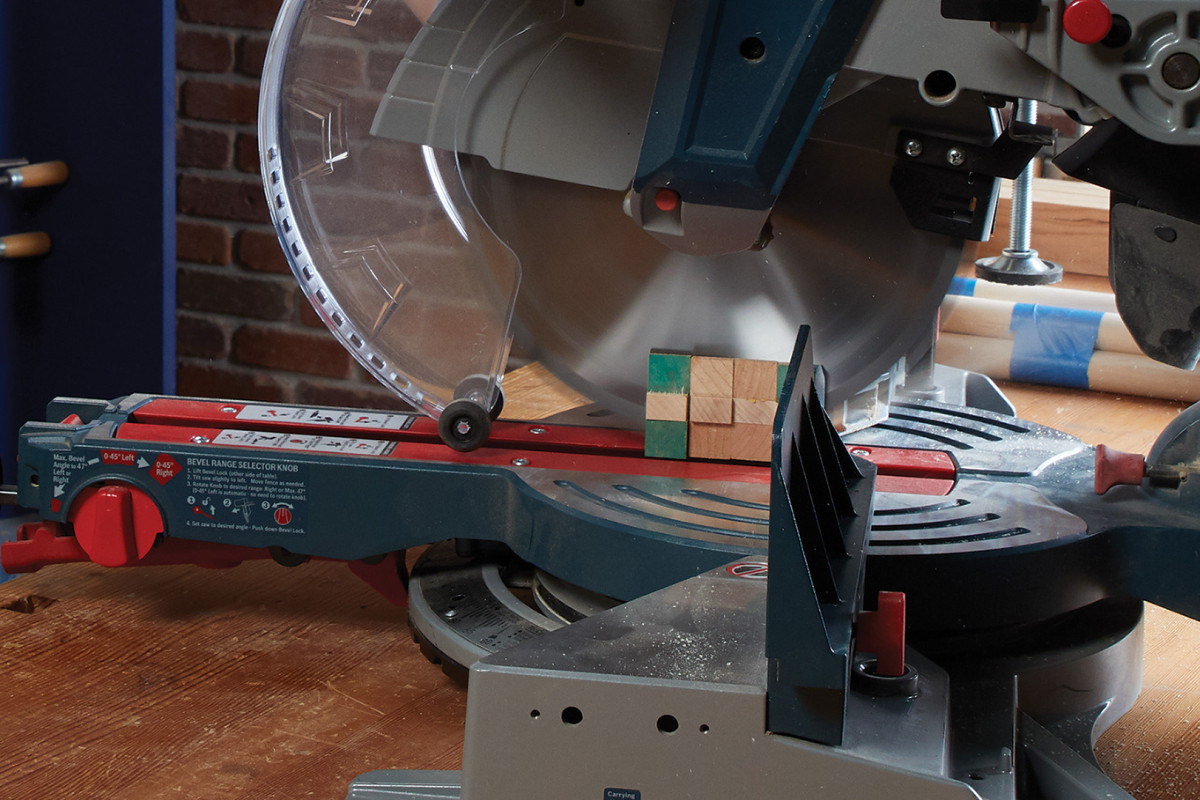

Getting the dowels ready is the easiest part of this build — simply trim six 1“ dowels to 25-1/2“ long and sand lightly. That’s it!

You can’t see it from this angle, but these dowels are taped together to prevent them from shifting while cutting.

Gang cutting all four sides at once will guarantee they’re all the exact same length

Drill Some Holes

Now that your sides are assembled, it’s time to drill the holes for the dowels and score-keeping system. Install a 1“ Forstner bit into your drill press, and set your fence so the hole will be exactly centered on the sides. Drill the three dowel holes on each side, centered 13“ apart. Next, swap in a 3/8“ bit to drill the hole for the feet. Drill the hole in the side first, then use it to align the hole for the legs. You’ll also want to drill a small recess for the t-nut.

The contrasting wood pattern will make any inaccuracy more noticeable, so take your time setting the fence.

Drill the hole for the threaded knob into the side first, then use that as a guide for the leg hole

You don’t have to include a way to keep score on your ladder golf set, but it really elevates the build — pick one side piece and drill two rows of 21 holes each running between the top middle rungs.

You only need to keep score on one side.

Assembly

The assembly process from here is fairly direct—the dowels need to be glued into the respective openings. There are a few things to pay attention to though.

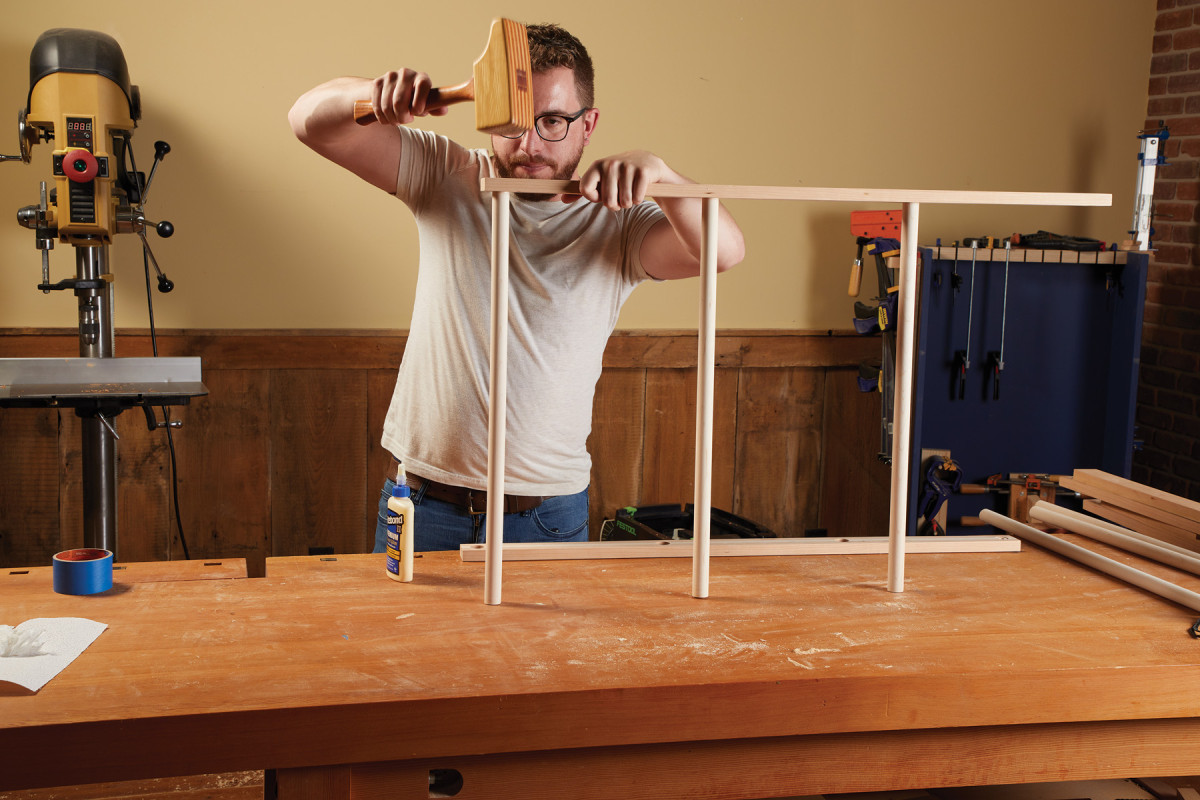

Start your dowels with the side laying on your workbench. If they’re not wanting to go in, now is your chance to sand a bit more.

While a dry-fit test run is usually a good idea, dowels tend to like to bind, which can cause complications. What you’ll want to do is take note as you’re assembling to make sure nothing is fitting too tightly in a way that would split the wood. If it really feels like a dowel doesn’t want to go in, take the time to sand it down a bit more.

Once all three dowels are started, flip the piece over and finish tapping with the mallet until each one is flush.

Once you’ve completed assembly of a ladder, make sure it lays flat on your workbench while the glue is still wet. The sides need to be parallel to make sure it sits evenly on your lawn.

Unlike the dowels, the t-nut should be installed with a hammer.

Oh, and don’t forget to make sure your score holes are facing outward!

Finishing and Final Steps

Finishing is usually the last step of the process, but there’s a correct order of operations that will make your life a bit easier. Once the glue is totally dry, finish the ladder golf set with an exterior finish of your choice (I used spar urethane) and allow to set. Then, go ahead and install the t-nut for the side/leg connector. Installing this after you stain gives you one less thing to stain around and helps ensure better protection against moisture.

Add a fun pop of color with the score pins.

For the score keeping rods, cut one 1“ piece of brass rod, and another one of aluminum rod, and lightly sand. For the color drops to the end, I used model car paint for a nice high-gloss metallic look. You’ll definitely need to sand down the end that goes into the hole a bit so it’s easy to move the rods as the game goes on. Sand too much though and they’ll be inclined to fall out.

And there you have it! To set up, simply affix the sides to the legs using the threaded knob, and then go have fun!

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.