We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Capture the fleeting beauty of melting icicles by turning a hollow ball and two small spindles into a beautiful Christmas tree ornament.

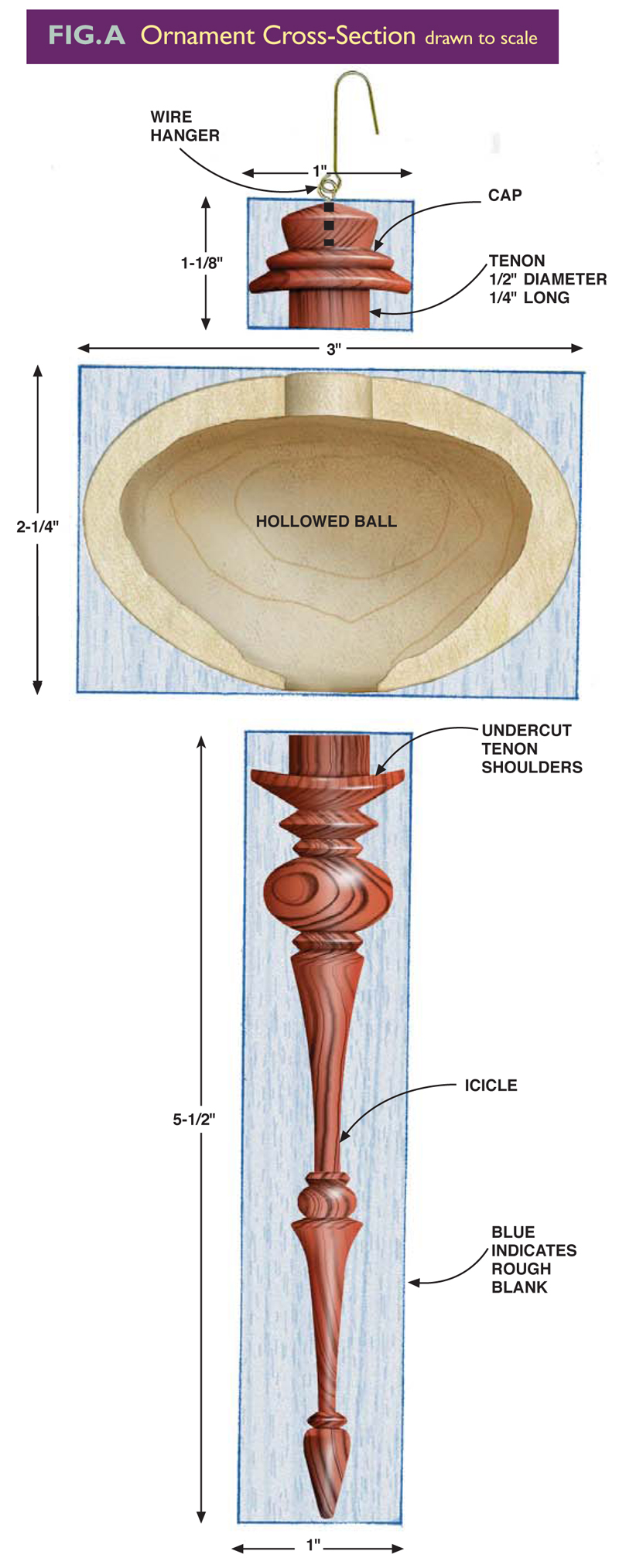

This project requires a fair amount of turning experience. If you’re patient, however, you’ll find that making this ornament is a good way to learn new techniques. Shaping a delicate spindles takes practice, but you can make up the shape of the icicle as you go. If you’ve never hollowed a vessel before, this ball is an easy first project—the inside doesn’t have to be smooth and polished. The ball is hollow to reduce its weight.

Choose a light-colored wood with interesting grain for the ball. It should be one solid piece, 2 1⁄2- to 3-in. square. I like to make more than one ornament at a time, so I use a rough blank about 8-in. long in order to make two balls. Make the cap and icicle from a contrasting dark wood that takes fine details. I like to use rosewood or ebony. You’ll need a piece that’s 1-in. square and 8-in. long.

You’ll need a scroll chuck, a Jacobs chuck and a live center as well as a small hollowing tool and tools for turning a small spindle.

Begin by mounting the stock for the ball between centers and turning it into a cylinder.

1. Turn a tenon to fit your chuck. Then mount the cylinder in the chuck with the shoulders firmly resting on the chuck’s jaws.

2. Shape the ball into a compressed sphere. Turn the neck to a 1-in. diameter. Stop the lathe and pull back the tailstock in order to clean up the end of the ball. A good chuck will securely hold the work without the support of the tailstock, but make light cuts.

3. Bore the end of the ball with a 1⁄2-in. bit mounted in a Jacobs chuck. Set the lathe at its lowest speed. Put a piece of tape on the bit if you need a depth stop. The hole must go completely through the ball. Steady the bit with your hand to dampen any severe vibration.

4. Scrape the interior of the ball with a small hollowing tool, using light cuts. Frequently clear out the waste with a shop vacuum or a blast of compressed air. The purpose of hollowing the ball, which can be rough inside, is to reduce its weight.

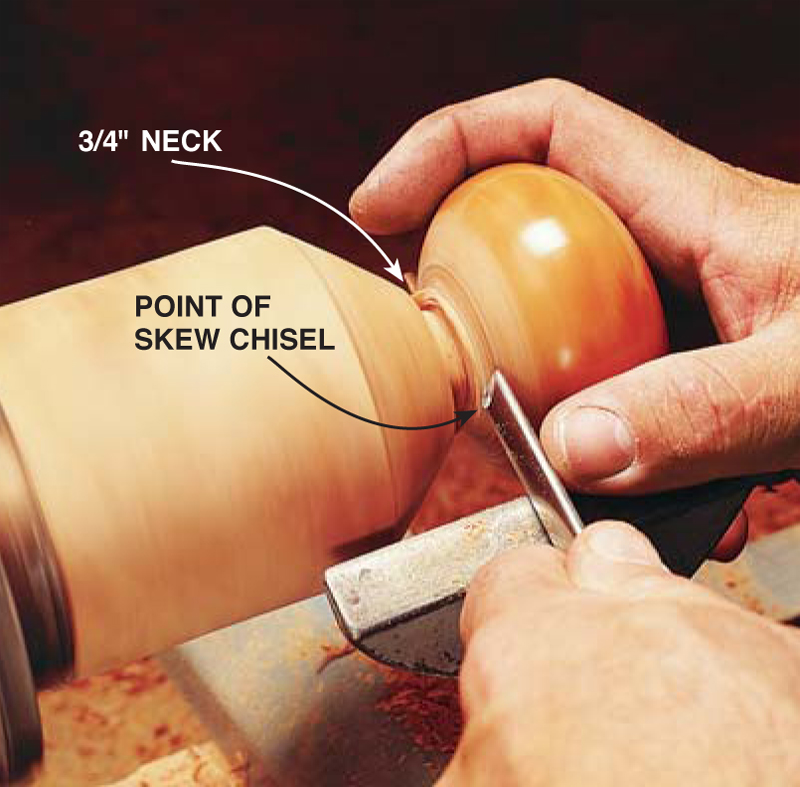

5. Apply a padding finish to the ball as it spins on the lathe.Then reduce the diameter of the neck between the ball and cylinder down to about 3⁄4-in.

6. Part off the ball with a skew chisel’s shearing cut. Ride the bevel of the chisel on the work.The ball will fall off into your hand when you reach the 1⁄2-in. hole. You can use a parting tool instead, but then you’ll have more sanding to do.

7. Reverse the ball and mount it on a stub tenon that you’ve turned on the cylinder. Support the other end of the ball with a live center inserted into the hole. Now you can clean up any marks left by the skew chisel. Sand and finish the rest of the ball.

8. Size a tenon on the cap piece to fit the ball’s hole. Undercut its shoulders, too. The cap piece, as shown here, is glued into a shallow hole turned into the face of a waste block. Shape the cap, then part it off the waste block. To clean up the tip, reverse the cap and push the tenon into a new hole in the waste block. Finish the cap on the lathe, then remove it and drill a small, shallow hole for the hanging wire.

9. Support the spindle with one hand as you cut icicle shapes. First turn a tenon at the tailstock end to fit the lower hole in the ball. Undercut the tenon’s shoulders so the icicle fits tight on the rounded bottom of the ball (Fig.A).Then turn the larger diameter cove, beads and fillets. Move downhill towards the headstock to cut the smallest diameters last. Apply a finish.

10. Drip cyanoacrylate (CA) glue into the ball while holding the cap in place.This will firmly anchor the ball to the cap. To attach the hanging wire (see Sources, below), place a drop of glue on top of the hole and push in the wire. Apply glue to the icicle’s tenon and place it in the bottom hole. Slow setting CA glue works best for oily exotic woods such as rosewood and ebony.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.