We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Umbrella Stand

Build this simple, elegant stand and you’ll have it made in the shade come summer.

By Dave Munkittrick

| Market umbrellas have a certain magical quality to them. Whether you’re ducking in out of a soft summer rain or seeking relief from the noonday sun, once you slip under that protective canopy, a cozy, intimate atmosphere invites you to sit down and relax for a while.

Our cedar stand is the perfect complement to the brightly colored market umbrellas that have become so popular. Unlike typical patio tables that force most of the sitters out in the open, the small footprint of our cedar stand keeps you inside the umbrella’s sheltering shade.

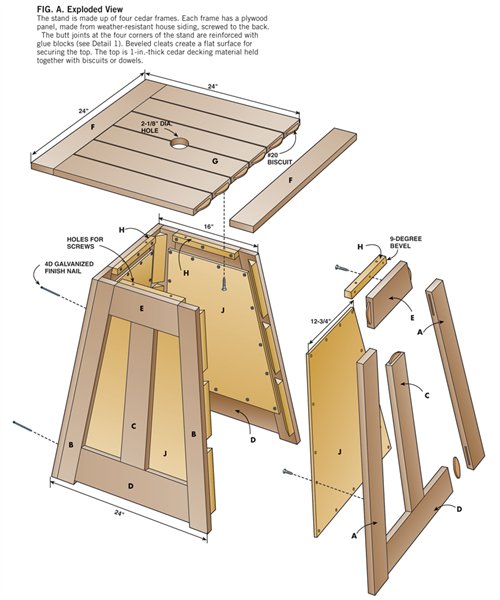

What you’ll need to get startedOur stand can be built in a day using home center materials. We chose “select”-grade cedar decking for the top and lower-cost #2 cedar for the base. Plan to buy a little extra of the lower-grade cedar so you can harvest the clear wood between the knots. Pick straight-grained boards, especially for the stiles (A and B). This helps make the butt joints where the sides come together almost invisible. The T 1-11 plywood used for the panels is typically used for house siding. It has a rough surface and is made with weather-resistant adhesives so it’s perfectly suited for staying outside in the elements. Be sure to get the stuff that doesn’t have grooves cut in it. Butt joints and biscuits are what we used to build this sturdy little stand. But, the only tools you need to complete the project are a tablesaw and a jigsaw. A biscuit joiner, miter saw, circular saw and a 2-1/8-in. holesaw are nice to have, but none of these tools are required. If a biscuit joiner and miter saw are still on your wish list, the angled cuts can be made on your tablesaw and the side-panel frames can be glued up with simple butt joints. Biscuits help keep the frame parts aligned, but the plywood panel screwed to the back (Fig. A) will reinforce the joints even without biscuits. Dowels work just fine for assembling the top and a jigsaw is a good substitute for the holesaw and circular saw.

Working with cedarA couple things to keep in mind when working with cedar: First, cedar is very prone to chip-out when cross cut. Always use a sharp, fine-tooth blade. And even though a miter saw is often called a chop saw, don’t “chop” the wood. Take it slow and easy for smoother cuts. The second thing to remember is that cedar can be very wet. I strongly recommend you rough cut the boards oversize first, then stack the pieces so air can circulate around all the surfaces. Cedar dries fast, and the shorter lengths will dry even faster—a few weeks should do the trick.

Build the umbrella stand1. Make two pair of side panels. One with skinny stiles (B) and one with wide stiles (A). 2. Cut the angled ends on all the frame pieces (A, B, D and E) at 9 degrees (Photo 1). Note: After the first cut is made on each rail, you’ll have to flip it over and make the second cut from the back side to avoid changing the angle setting on the saw. 3. Assemble the frames with biscuits and a water-resistant glue like Tite Bond II (Photos 2 and 3). 4. Cut the plywood panel blanks according to the Cutting List, page 59. Cut the tapers (Photo 4) with a circular or jigsaw and screw them to the backs of each frame. 5. Assemble the stand with water-resistant glue (Photo 5). Use glue blocks to help reinforce the butt joints (Fig. A, Detail 1). 6. Glue up the top (Photo 6). Cut the hole for the galvanized pipe with a 2-1/8-in. hole saw. Drive a wedge of wood between the two middle boards to give the drill bit a place to bite. A jigsaw can be used if you don’t have a hole saw laying around. 7. Set the pipe (K) in a bucket of concrete (Photo 7). 8. Place the bottom half of the umbrella pole in the pipe and drill a 1/4-in. hole through the pipe and pole. Use a 1/4-in. eyebolt to secure the lower half of the umbrella pole to the base. 9. Set the cedar stand over the cement base and screw on the top half of the umbrella. 10. Enjoy the shade and a cool drink—you deserve it! Oops!Shoot! We tried clamping the stand without using nails to pin the panels and one of them slid up under clamp pressure. The result: Uneven feet! Because the glue was set there’s only one fix. Put the stand on a flat surface (like your tablesaw). Set a compass to match the widest gap, and run a line around each foot, referencing the compass off the tablesaw top. Finally, cut or sand the feet flush to the scribe line for a neat appearance. No one will ever know. Sources(Note: Product availability and costs are subject to change since original publication date.) Home Center, One 4 x 8 sheet T 1-11 siding (no grooves); Cutting ListFig. A: Exploded ViewFig. B: Weighted BaseDetail 1: Glue BlocksThis story originally appeared in American Woodworker January 2003, issue #98. |

Click any image to view a larger version.

1. Cut the angled frame members (A through E). Use a 9-degree angled stop block to fit the angled ends of each frame member. The stop block ensures that all similar parts of each frame are the same length. That in turn ensures that all four sides of the stand will be exactly the same size and have the same angles.

2. Cut biscuit slots with a simple hold-down jig. The jig’s base completely supports the joiner base. The toggle clamp holds the board down flat on the jig allowing you to keep both hands on the joiner for quick, accurate and safe slot cutting. Any clamp can be used to hold down the board; the toggle clamp just speeds things up.

3. Assemble the frames starting with the center stile (C) and the top and bottom rails (D and E). Use water-resistant glue and clamp the stiles onto the rails. Offcuts from the angled ends make perfect clamp pads that won’t slip as clamp pressure is applied. After the glue has dried, sand the frames to remove any unevenness at the joints.

4. Cut the tapers on all four plywood panels at the same time. Close counts with these cuts. A circular saw works best but a jigsaw will get the job done. Clamping all four blanks (J) together onto a pair of sawhorses keeps the parts from slipping and both of your hands safely on the saw. After they’re cut, fasten a panel to the back of each frame.

5. Assemble the base with notched cauls. Notches on the edge of a 2×2 create parallel clamping surfaces so your clamps stay put. Use an angled offcut as a pattern to lay out the notches. Cut them out with a jigsaw, bandsaw or by hand. Pin the sides with a couple of 4d galvanized finish nails at each joint to keep the sides in place while clamping. Add glue blocks and cleats (H) (Fig. A, Detail 1).

6. Glue up the top using 1/8-in.-thick spacers to set an even gap between the boards. Biscuits make quick work of fastening the breadboard ends, but dowels would also make a strong joint. Trim the top to final size (Fig. A). Sand the top smooth, then turn the stand upside down on your bench with the top underneath. Secure the top with screws through the cleats.

7. Use a level to plumb a 2-in. galvanized pipe in a bucket. A couple strips of 1/4-in. plywood will help position the pipe. Seal the bottom end of the pipe with a little duct tape and mix up one bag of concrete in the bucket. Then push the pipe through the wet concrete to the bottom of the bucket. Make sure your bucket is on a level surface. |

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.