| A coffee table isn’t just for coffee. It displays interesting reading and serves the Saturday night pizza. It hosts Scrabble games, labors under kids’ crafts and gives you a place to rest your feet. It’s a real workhorse that has to be well built and versatile.

Our table is rock-solid, featuring mortise-and-tenon joints, splines, and dovetailed drawers. It’s also easy to build, because simple, shop-made jigs ensure perfect-fitting joints. Its two drawers act like four, because they open from both sides. A standard dovetail jig is all you need to make them. Rare-earth magnets work like magic as two-way drawer stops (see Sources,

below).

This table requires only 25 bd. ft. of

4/4 stock and 9 lineal ft. of rough-cut

2-in.-square stock. If you don’t have a

jointer and planer,buy turning squares

and rip them down to make the legs

(see Sources, below). Buy 3/4-in.-

thick boards for everything else but the

drawer sides. Get 1/2-in.-thick boards

for them and a 2 ft. by 4 ft. piece of

1/4-in. plywood for the drawer bottoms.

We built our table from cherry,

and used birch for internal parts and

drawer sides. Our cost, including onehalf

sheet of 3/4-in. birch plywood for

the jigs and clamping cauls, came to

about $250.

The only must-have power tools for

this project are a tablesaw and a plunge

router equipped with an edge guide.

You’ll also need a drill, a coping saw, a

sharp 1/4-in. chisel, glue and the usual

assortment of clamps, including four

4-ft. pipe clamps.

Start at the Top

I always make the top of a table right off

the bat, for two reasons. First, it’s the

most important part, visually, so it

deserves the best-looking boards. Make the aprons, rails and drawer fronts from

the leftovers.

Second, you can start finishing the

top early, so the finish will have plenty

of time to cure.This is especially important

if you plan to build up layers of

finish for long-lasting protection. Be

sure to apply equal layers to both sides

of the top, to keep it stable.

I like to use hide glue when I work

with cherry,because of its dark color. Its

long open time also makes it easy to

fine-tune the joints between the top

boards (Photo 1). Wait 24 hours before

you remove the clamps.Hide glue takes

a long time to dry.

Cut the top (A) to size, smooth it

and soften all the edges. I use a router

with a 1/8-in. round-over bit for this,

but sandpaper and a block will work. If

you have children, you may also want to

round the four corners for safety.

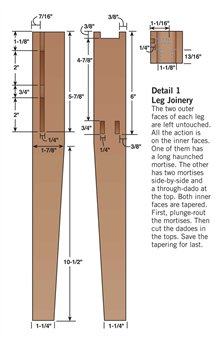

Size Up the Legs

The four legs (B) are mortised, dadoed

and tapered (Fig. A, Detail 1), but

they’re not identical. Be sure to make

two opposing pairs, one left- and one

right-sided. Mark your blanks carefully,

so you don’t mess up! You’ll need

all three jigs (Figs. B, D and E) to complete

the legs; I find it easiest to make

them as I go.

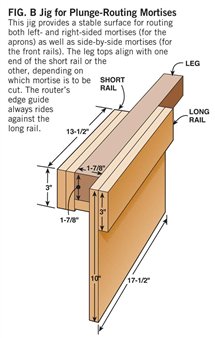

Plunge-Rout the Mortises

Use one of the leg blanks for sizing

when you build the mortising jig (Fig.

B). Make sure the leg fits snugly

between the rails of the jig and is perfectly

flush with them at the top.

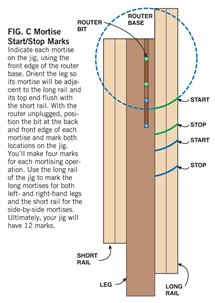

Plunge-rout mortises for the aprons

(Photo 2 and Fig. A, Detail 1), after

marking the start/stop points (Fig.C).

All four mortises are cut with the edge

guide at the same setting. Create the

groove for the haunched tenons (Fig.F)

by routing the first couple passes full

length.Then use the start/stop marks to

finish plunging the individual mortises.

Next, plunge side-by-side mortises

for the lower rails (Fig. A, Detail 1).

Both of them are cut from the same

edge guide setting. After cutting the

first mortise, flip the leg end-for-end to

cut the second. Each mortise has its

own pair of start/stop marks.

By flipping the leg, the side-by-side

mortises will be perfectly centered and

their outer shoulders will be identical.

After routing, square the ends of the

mortises (Photo 3).

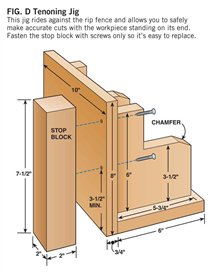

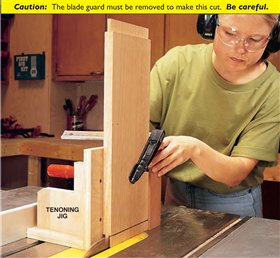

Cut Dadoes and Tapers

The top rail joins the leg in a lapped

joint (Fig. H). The leg has a centered

through-dado on its top end. To cut

this dado safely on the tablesaw, clamp

the leg in the tenoning jig (Fig.D) and

make two passes (Photo 4). Be sure to

dado the face with the side-by-side

mortises.

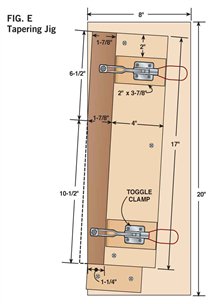

Building the tapering jig (Fig. E),

takes longer than using it to taper the

legs! Orient the leg so you can clamp it

flat on the jig for both tapering cuts

(Photo 5).

Make the Aprons

When you machine the apron blanks

(C),make an extra one.Use it for testing

when you set the blade and fence on

your tablesaw.Cut the tenon shoulders

first, using the miter gauge and rip fence

(Photo 6). Be careful when you set the

blade height. A cut that’s too deep will

weaken the tenon.

This cut establishes the tenon’s

length. Be sure to include the width of

the saw kerf when you set the rip fence

(with a standard 1/8-in. kerf blade, setting

the fence at 7/8-in. results in a 1-in.-

long tenon).

Next, set the blade and fence for cutting

the tenon cheeks,using a test piece

with correct shoulder cuts. Test the fit,

using one of the mortised legs.

In this operation, the fence setting is

most important because it determines

the thickness of the tenon (Photo 7).

The blade height isn’t as critical.Being

a bit too deep won’t weaken the tenon.

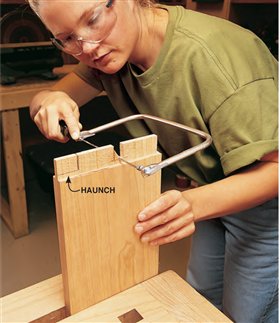

After the cheeks are cut, saw individual

tenons from the full-length

blanks (Photo 8 and Fig. F). Cut the

ends straight, so they fit the mortises.

The haunches don’t have to be precisely

cut, as long as they’re short enough to

allow the joint to close.

Glue the Legs and

Aprons Together

Finish-sand the legs and aprons.Then

soften the outside bottom edge of both

aprons with the 1/8-in. round-over bit.

Soften the edges of the legs too, except

for the ones on the face with the sideby-

side mortises, where the front rails

will be attached.

Glue and clamp each side assembly

(Photo 9). Be sure the top of the apron

is flush with the tops of the legs.

Remove squeezed-out glue, before it

hardens,with a damp cloth.

Make the Rails Together

Machine the rail blanks (D and E),

along with extra blanks for the drawer

dividers (F) and to use for test cuts.

Although the upper and lower rail joints

are different (Fig.H) and the lower rails end up being shorter, the four rail

blanks must be identical, and cut square

on both ends.

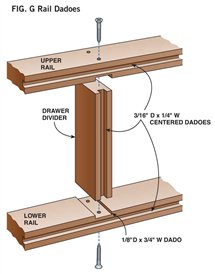

First, cut dadoes for the drawer

dividers across the inside faces of all

four rails (Fig. G). These dadoes must

be carefully sized to fit the dividers and

precisely centered on the rails. Equip

your miter gauge with a fence and stop

block to make these cuts.

After cutting the dadoes, separate

the rails into pairs and cut the tenon

shoulders (Photo 10). Make a third

shoulder cut on the inside faces (the

ones with the dadoes for the dividers) of

the two upper rails (Photo 11).

Next, remove the waste from the

tenon sides. Clamp a test piece on the

tenoning jig, with its face against the

stop block. Raise the blade, set the fence

and cut the outer side of the tenon.

Then rotate the test piece 180 degrees

and cut the other side.

Test the tenon’s fit in the leg-top

dadoes. Adjust the fence, if necessary,

and finish cutting the tenons on all

four rails.

Finish the Rail Joints Separately

Re-mount the upper rails in the tenoning jig and

cut their half-lap tenon cheeks (Photo 12).

Shorten the lower rails so the tenons extend

only 3/4 in.Then mark these tenons so you can cut

them into the side-by-side tenons (Photo 13). Cut

their inner shoulders using the tenoning jig, rotating

the rail between cuts. Remove the waste

between the tenons with additional passes over the

saw blade.

Dado the Rails and

Drawer Dividers

Cut shallow 1/4-in.-wide dadoes in the back of all

four rails (Fig. G). These dadoes will be used to

align and attach the drawer supports, so they must

be accurately centered. Cut them on the tablesaw,

using your regular ripping blade. Set the fence

and make a pass dead center.Then reset the fence

1/16-in. off-center and make two more passes,

first one face, then the other, against the rip fence.

Dado the back edges of the drawer dividers,

too. Rather than dadoing each short divider, it’s

safest to dado a long blank and cut the dividers

from it.

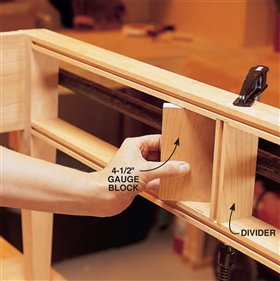

After drilling countersunk pilot holes for screws

in the rails, dry-assemble the base on a flat surface.

Clamp it together and test the drawer openings

with a gauge block (Photo 14).

Glue the Base Together

Hide glue is a good choice for this job. Its long open

time gives you the opportunity to check the drawer

openings and measure diagonals to make sure

everything is square before you drive the screws

(Photo 15). Be sure to work on a flat surface.

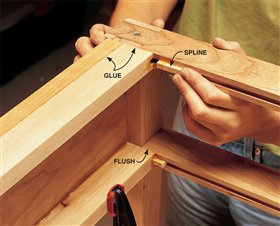

Cut the drawer supports (G and J) to length

and dado their ends to match the dadoes on the

rails, using the tenoning jig. Then make the splines

(H and L).Apply glue, slide the supports in place

and insert the spline.Make sure the support stays

flush with both rails when you add the clamps

(Photo 16).

The ends of the center drawer guide (K) are

also dadoed. Splines keep it flush with the dividers

(Photo 17). Glue the outer drawer guides (M)

flush with the inner leg faces. Install the upper

center drawer support last.

Drill countersunk pilot holes through all three

upper supports for fastening the top with screws,

dead center (Fig. A). Then drill slightly larger

diameter holes in the upper rails so the top has

freedom to move with changes in humidity.

Make and Install

the Drawers

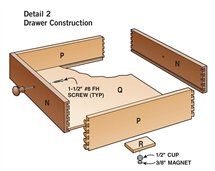

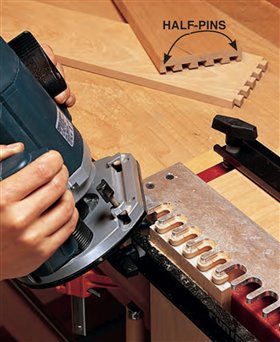

We used a dovetail jig and standard

bit to make our drawers (Photo 18).

Their finished length is 3/8-in. shorter

than the pass-through openings, so

they’ll sit 3/16-in. back from both

fronts. This reveal matches the ones

between the legs and aprons. The

length of your drawer sides (P) may

vary from ours, depending on the

length of the dovetail your jig makes.

For a good fit, the drawers should

be up to 1/16-in. narrower, but only

1/32-in. shorter than the front openings.

Center the dadoes for the drawer

bottoms (Q) in the lowest dovetail

socket of the drawer fronts and on the

corresponding tails of the sides.Then

they’ll be hidden when the drawer is

assembled.

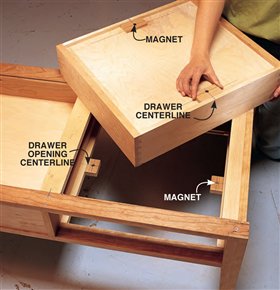

Rare-earth magnets (see Sources, below) act as two-way drawer stops.

Mount them in pairs (one on the

drawer bottom, the other on the

frame), on both sides of each drawer.

They’re self-aligning, so they’ve got to

be precisely located, end-to-end and

side-to-side.

Install each magnet in a block (R

and S). Mount the blocks temporarily

until you get them in just the right

spots. Then glue them in place.

The rare-earth magnets we’ve chosen

are strong enough to work great

even when the drawer is loaded down

with ten pounds of magazines.However,

you should keep magnetic

media, including credit cards and

videocassette tapes out of the drawers.

The magnets will damage them.

Finals

If applying a finish always seems like

a chore, cherry is a great wood to

work with. Even the simplest wipe-on

oil finish will make it look great. For

durability, choose one with urethane

resins. A brushed-on polyurethane

varnish will stand up even longer.

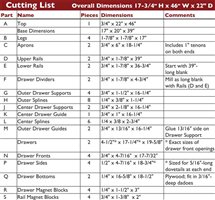

Cutting List

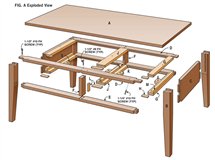

Fig. A: Exploded View

Detail 1: Leg Joinery

Detail 2: Drawer Construction

Fig. B: Jig for Plunge-Routing Mortises

Fig. C: Mortise Start/Stop Marks

Fig. D: Tenoning Jig

Fig. E: Tapering Jig

Fig. F: Haunched Apron Tenons

Fig. G: Rail Dadoes

Fig. H: Rail Tenons

Sources

Note: Product availability and prices are subject to change.

Adams Wood Products, adamswoodproducts.com, 423-587-2942, Cherry Turning Squares,

2-15/16″ square x 22″ long

ASQ3322-3.

Lee Valley Tools, leevalley.com, 800-267-8767, Toggle clamps

#88F05.01;

Rare-earth magnets,

4 sets req’d,

3/8″ disc #99K32.03, 1/2″ cup #99K32.52.

Smith Design and Woodworks, niceknobs.com, 908-832-2723, Drawer Knobs

SO-118. |

|

You may also like…

Shaker Table

Arts & Crafts Bedside Table

Walnut Coffee Table

Click any image to view a larger version.

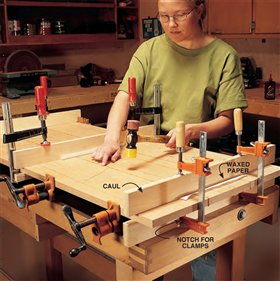

1. Use your best boards for the top. Choose ’em and use ’em right away,

so you don’t get caught short later. Cauls above and below keep the boards aligned

and flat during glue-up. Use a non-marring mallet to make minor adjustments.

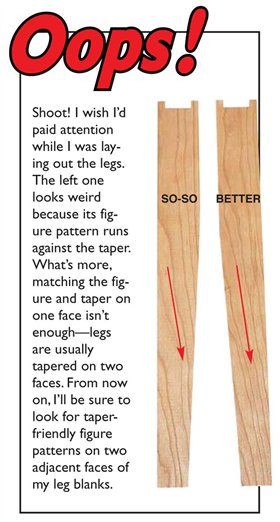

Oops!

2. Plunge-rout the mortises, using the router’s

depth-stop turret to increase the depth of each pass. If

you have a variable-speed router, you’ll get a smoother

cut if you slow it down by about a third. Start/stop marks

let you cut the mortises without stop blocks.

3. Square the ends of the mortises, using a block

clamped on the layout line to guide the chisel.

4. Center a wide dado in the top of each leg, using a

shop-made tenoning jig. Make two passes, one on

each opposing face, so the shoulders are the same thickness.

5. Taper the two mortised faces. Clamp the leg

with one mortised face toward the blade and the other

face down on the tapering jig. After cutting

the first taper, rotate the leg clockwise to cut the

second taper.

6. Cut shoulders in the aprons with the blade set to leave 1/4-in.

remaining in the center. You can use both the miter gauge and rip fence for

this operation because you’re not making a through cut.

7. Cut apron tenon cheeks using the tenoning jig. Set the blade height to

score the tenon shoulder. Then adjust the tenon’s thickness with the rip fence.

Make two passes, one on each side of the apron.

8. Finish sawing the tenons with a coping saw or on

the bandsaw. Be careful with your layout to make sure the

haunches are properly located.

9. Glue the side assemblies. Brush hide glue on the walls of the mortises

and on the tenon cheeks. Use blocks to distribute the pressure when you

clamp things together.

10.Cut the rails’ tenon shoulders simultaneously. Gang

them together in pairs, one upper and one lower, and make

sure they’re precisely mated when you make the cuts.

11. Cut half-lap shoulders on the inside faces of both

upper rails. Use the same setup you just used to cut the

tenon shoulders.

12. Cut half-lap cheeks on the inside faces of the upper

rails, using the tenoning jig. Orient the rail so the offcut falls

out of harm’s way.

13. Mark the inside shoulders of the two lower-rail

tenons right from the mortises on the leg, after shortening

the rail’s long tenon.

14. Fit the drawer dividers while the base is clamped

together in a dry assembly. A shop-made gauge block

that measures the width of the drawer opening lets you

know when the dividers are the right length.

15. Screw the upper rails to the legs when you glue up the base.

These open joints benefit from the mechanical assistance of screws.

16. Wooden splines perfectly align the runners and rails, just

like a tongue-and-groove joint.

17. Slip the center drawer guide over the

splines, and glue it to the dividers and the lower rail.

18. Dovetail the drawers, using a

standard jig. They’re sized so you’ll

end up with half-pins at the top and

bottom of the drawer fronts.

19. Carefully positioned rare-earth magnets stop

the drawers dead center, so you can shut them from

either side. |