We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Q & A: Mortise and Tenon Dimensions

Q:

I would like to use mortise

and tenon joinery on a

project. Are there any rules

of thumb for sizing mortise

and tenon joints?

A:

Here are a few good

rules of thumb for designing

a mortise and tenon joint:

For strength, a tenon

should be at least twice as

long as it is thick. Thus, a

1⁄4-in. thick tenon should be

at least 1⁄2-in. long. The thickness

of the tenon is dependent

upon how wide the

mortise can be made.

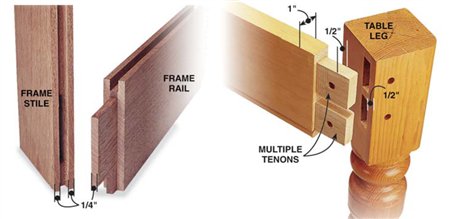

In frame construction

where the stile and rail thickness

is the same, the tenon

should be no more than one-third of the total

thickness of the rail. Keeping the sides of the

mortise at least as thick as the tenon produces

the strongest possible joinery (see

photo above).

If the piece into which the mortise is cut

is wide enough to allow a set back, as when

a table leg is joined to an apron, then the

tenon width can be increased to as much as

half the thickness of the piece from which it

is cut (see photo above).

The width of the tenon is largely a function

of the width of the piece it is cut from. Try to

maximize the width for the glue surface while

leaving enough of a shoulder for mechanical

strength. If the tenon is more than 3-in. wide

it is best to cut multiple tenons to better

accommodate the expansion and contraction

of the wood across the grain (see photo above).

|

This story originally appeared in American Woodworker October 1999, issue #75. |

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.