Oval frames are delightful eye-catchers, evoking

images of days gone by and giving a unique setting

for that very special photo. At first glance these frames

may look tricky, but we’ve figured out an easy way to

make them and you don’t even have to know how to

draw an oval. Simple-to-make jigs and patterns are all it

takes. In fact, this method can be used to make almost

any size oval or round frame.

Oval frames in four easy steps

The four basic steps to making an oval frame are:

1. Create a frame pattern using a piece of oval glass,

some 1/4-in. plywood and a couple of washers (Fig. C

and Photos 1 through 5).

2. Prepare the frame parts for routing. This involves cutting

the miters to size, gluing them together and rough

sawing the oval shape (Fig.B and Photos 6 through 9).

3. Make the router jigs and rout the frame to final size

and shape (Figs.A, E,F, G and H and Photos 10 through

13).

4. Finish your frame and install the glass,mat, picture

and an oval screw ring (see Sources, below) and it’s

ready for the wall.

Materials and tools

It takes only 2 bd. ft.of 1-1/8-in.-thick lumber to make

one of the frames shown here. The jigs can be built

from scrap 3/4-in. plywood or medium-density fiberboard

(MDF). You can buy oval glass from a picture frame

shop or by mail order (see Sources, below). Your framing shop

should be able to make you an oval mat. You can also cut your own glass and mat and

save a bunch of money (see Cutting Your Own Ovals, below).

The tools you need to build the jigs and frame are a tablesaw, a jigsaw, a router with a 1/2-in.

collet, and a drill press with a drumsander

attachment.You will also need a

flush-trim, rabbet, 45-degree chamfer,

and Roman-ogee router bit, and a slot

cutter (see Sources, below). If your

lumber is rough sawn you’ll need a

planer and jointer. A router table and

either a belt sander or disc sander are

also handy but not absolutely necessary.

Router table vs. router jigs

There are a couple of steps (Photos 12

and13) that can be done on a router

table or with the frame-holding jigs

(Figs. G and H). I opted for the jigs

because I think they’re safer and easier

to use.When I tried making these cuts

on the router table, I found holding the

frame with push blocks awkward

because they tended to slip off the narrow

frame during routing. I did use the

router table to cut the spline slots (Photo

6) because it’s quick and accurate, but

the slots could just as well be cut on the

tablesaw.

Oops!

While developing this project we used several

types of wood: oak, pine,walnut and mahogany.

They all machined nicely except the mahogany. It

had a tendency to chip out when flush-trimming

the outside diameter.With a curved shape like

this you’re guaranteed to be routing against the

grain somewhere along the edge,making chip-out

likely.

If you do experience chip-out, the solution is to

sand the outside diameter of the frames rather

than rout them. You’ll have to do the sanding

freehand without the aid of a jig but it does the

trick and is almost as fast as routing. So if the

wood you choose gives you trouble with chipping,

give your belt or disc sander a try.

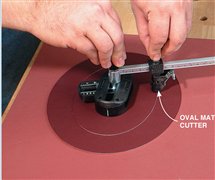

Cutting your own ovals

You can buy oval glass and mats or you can make your

own. They pay for themselves after about a half dozen frames.

These cutters cut ovals from as small as 4-1/4 in.by 7-1/4 in.

to as large as 21-1/2 in.by 24-1/2 in.They produce excellent

results and are easy and fun to use.

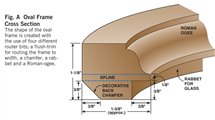

Fig. A: Oval Frame Cross Section

The shape of the oval

frame is created with the

use of four different

router bits; a flush-trim

for routing the frame to

width, a chamfer, a rabbet

and a Roman-ogee.

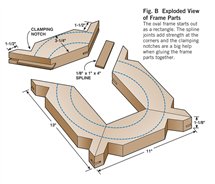

Fig. B: Exploded View of Frame Parts

The oval frame starts out

as a rectangle. The spline

joints add strength at the

corners and the clamping

notches are a big help

when gluing the frame

parts together.

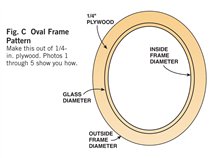

Fig. C: Oval Frame Pattern

Make this out of 1/4-in.

plywood. Photos 1

through 5 show you how.

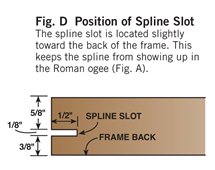

Fig. D: Position of Spline Slot

The spline slot is located slightly

toward the back of the frame. This

keeps the spline from showing up in

the Roman ogee (Fig. A).

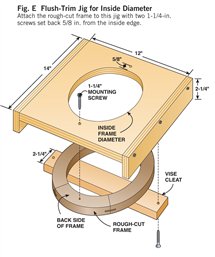

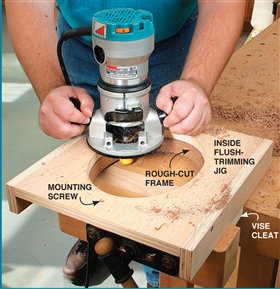

Fig. E: Flush-Trim Jig for Inside Diameter

Attach the rough-cut frame to this jig with two 1-1/4-in.

screws set back 5/8 in. from the inside edge.

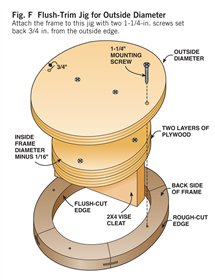

Fig. F: Flush-Trim Jig for Outside Diameter

Attach the frame to this jig with two 1-1/4-in. screws set

back 3/4 in. from the outside edge.

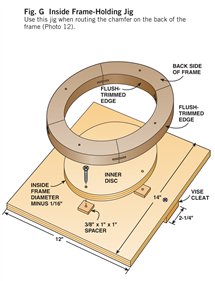

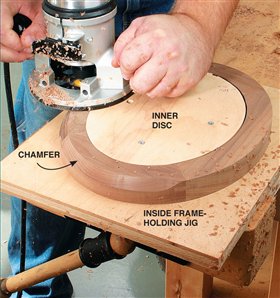

Fig. G: Inside Frame-Holding Jig

Use this jig when routing the chamfer on the back of the

frame (Photo 12).

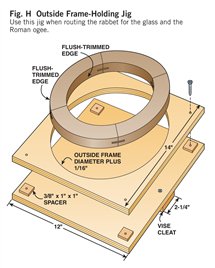

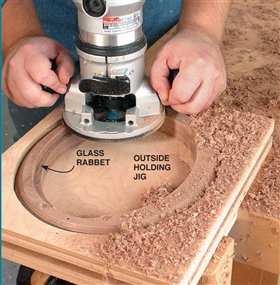

Fig. H: Outside Frame-Holding Jig

Use this jig when routing the rabbet for the glass and the

Roman ogee.

Sources

(Note: Product availability and costs are subject to change since original publication date.)

Hardware and Tools.com, hardwareandtools.com, Hillman Group 122321 Oval Screw Ring (3-pack), #u857458.

Victorian Frame Co., victorianframecompany.com, 877-576-1888, Oval-shaped flat glass, 8″ x 10″.

Rockler Woodworking and Hardware, rockler.com, 800-279-4441, Top bearing flush-trim bit, 1-1/4″ cutting length, #21046; Rabbeting bit set, #91595; 45-degree chamfer bit, #25162; Roman Ogee bit, #91639; 1/8″ 3-wing slot cutter; #91750.

M&M Distributors, mmdistributors.com, 800-526-2302, Logan oval and circle mat cutter, #1900; Fletcher oval/circle glass cutter #8461.

Rust-Oleum American Accents paints are

available at hardware and paint stores nationwide.

Gold metallic, #7954730.

This story originally appeared in American Woodworker March 2003, issue #99.

March 2003, issue #99

Purchase this back issue. |

|

Click any image to view a larger version.

We designed this frame for an 8×10 photo

without a mat or a smaller photo with a mat, but

you can make the jigs bigger or smaller to fit

almost any size photo.

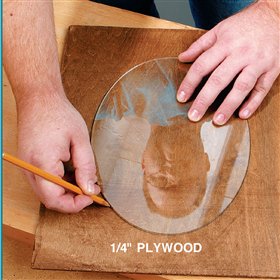

1. Start with your oval glass and trace it

onto a piece of 1/4-in. plywood.Then saw

out the inside with a jigsaw and carefully

drum sand right up to the pencil line.This

piece of plywood is your glass pattern.

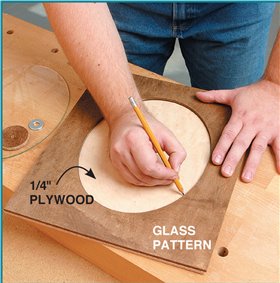

2. Trace around the inside of the glass

pattern onto another piece of 1/4-in.

plywood.This new piece of plywood will

become your actual frame pattern (Fig. C).

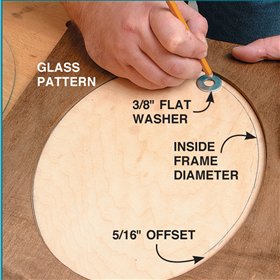

3. Use a 3/8-in. flat washer and trace

around the inside of the glass pattern.This

line marks the inside diameter of the frame.

Note:Any washer that produces a 5/16-in.

or slightly bigger offset will work. Just make

sure the offset is not bigger than 3/8 in. or

the glass may not fit the final frame.

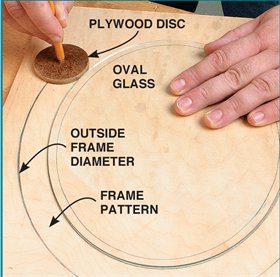

4. Draw around the glass using a 2-1/8-

in.-dia. plywood disc.This marks the

outside diameter of your frame. Use your

oval glass as a guide by centering it on the

line you drew earlier (Photo 2).

5. Complete the frame pattern by cutting

it out and sanding it to final size. Leave the

inside and outside diameter pencil lines. Be

careful to sand the oval evenly, without any

lumps or valleys.

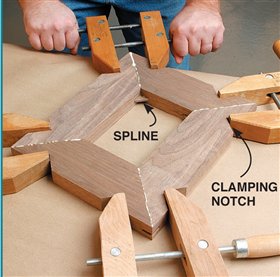

6. Rout the spline slots in the mitered ends

of your frame parts (Fig. D). Next make the

splines.They should slip easily into the

slots, but without a lot of play.

7. Glue the frame parts together using a

clamp at each corner. Use light clamping

pressure at first. Increase the pressure

once all the parts are correctly aligned.

Wipe off any glue squeeze-out while it is

still wet or scrape it off later.

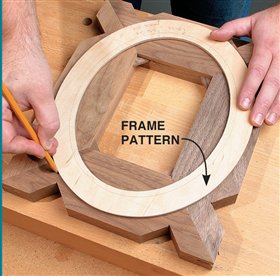

8. Draw around the inside and outside

of your frame pattern. The pattern

doesn’t need to be perfectly centered on

the frame material, just make sure you have

a little extra wood all the way around the

outside and inside.

9. Rough cut the glued-up frame with a

jigsaw. Leave about 1/8-in. extra wood

beyond the pencil lines.

10. Flush-trim the inside of the frame using a top-bearing, flushtrim

router bit. The rough-cut frame is held to the jig during

routing with two screws driven into the back of the frame.The jig

is held in the vise by a plywood cleat on the bottom of the jig (Fig.

E). If you are only making one or two frames, you could just sand

the inside flush using a drum stander and skip making the jig.

11. Flush-trim the outside frame diameter the same as you did

with the inside, except with a different jig (Fig. F).We experienced

some chipping when routing a mahogany frame (see Oops!, left), but the walnut we used for the frame shown here routed

cleanly.

12. Rout a chamfer on the back outside corner of the flushtrimmed

frame. Use the inside frame-holding jig (Fig. G). No

screws are needed to hold the frame to this jig, because the inner

disc keeps the frame in place.

13. Rout the rabbet for the glass in the back of the frame.This

time use the outside holding jig (Fig. H). No screws are needed

here either.This jig alone will hold the frame in place while

routing.Then flip the frame over and rout the Roman ogee on the

front inside edge.When you’re done routing, sand the frame and

you’re ready for finishing.

14. Finish your frames with your favorite finish.We added a

little sparkle to our frames by painting the inside edge with gold

metallic paint (see Sources, left).You can now install the glass,

mat and photo. |