We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Name That Chuck!

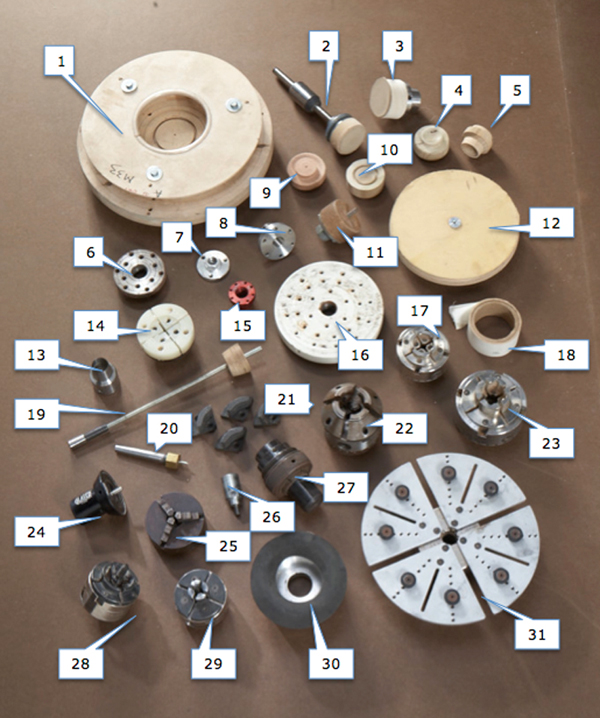

Here’s a chance to test your woodturning IQ. For many operations, a chuck performs the essential job of holding the work securely and safely on the lathe. These operations often present unique requirements, so a dizzying array of manufactured and shop-made chucks have evolved. How many of the 31 different chucks shown here can you identify? Click the photo to see a larger version. See below for answers.

Answers

1. Trapping chuck for reverse chucking. Turner made, it consists of a padded ring that bolts to a dedicated base that mounts on a faceplate. Part of a system with additional rings in different sizes to allow trapping work of all sizes.

2. Compression chuck for reverse chucking. Turner made, it consists of a block of MDF that’s covered with textured 1/8″ rubber and attached to a pulley with a 5/8″ bore. The pulley is mounted on a length of 5/8″ drill rod, which, in turn, is mounted in a machinist’s end-mill holder with a #2 Morse taper.

3. Compression chuck for reverse chucking. Turner made, consisting of a block of wood that’s mounted on a faceplate and covered with textured 1/8″ rubber.

4. Compression chuck used in ball making. Turner made, part of a set that includes Chuck No. 5, this chuck is held in a scroll chuck that’s mounted in the headstock.

5. Compression chuck used in ball making. Turner made, part of a set that includes Chuck No. 4, this chuck is held in position by a live tailstock center.

6. Solid steel faceplate, 4″ dia. with 12 holes.

7. Aluminum faceplate, 2-1/2″ dia., made to attach to a single center screw chuck with #2 Morse taper (No. 20), either as a 3-hole faceplate or as a larger base for the single center screw chuck.

8. Solid stainless steel faceplate, 3″ dia. with 6 holes.

9. Jam chuck made to fit inside a mortise. Turner made, it mounts on a faceplate or in a scroll chuck.

10. Jam chuck with a recess for holding a tenon or rim. Turner made, it mounts on a faceplate or in a scroll chuck.

11. Single center scroll chuck: Turner made, it’s simply a lag screw driven through a block of wood and mounted on a faceplate.

12. Backing plate for vacuum chucking. Turner made, it’s covered with a gasket material and mounts on a faceplate.

13. Ring chuck (also called a cup chuck).

14. Nylon jaws mounted on a four-jaw scroll chuck.

15. Aluminum faceplate, 2″ dia. with 8 holes; useful for small diameters and light work.

16. Cast iron faceplate, 8″ dia. with 30 holes.

17. Four-jaw scroll chuck with small spigot-type jaws.

18. Special double-sided tape.

19. Machinist’s-style collet chuck with a turner-made drawbar.

20. Single center screw chuck with a #2 Morse taper.

21. Serrated jaws for a four-jaw scroll chuck.

22. Four-jaw scroll chuck with a large, deep jaws.

23. Four-jaw scroll chuck with small spigot-type jaws that are serrated on the outside. These jaws are designed to expand inside a hole or recess.

24. Single-center screw chuck with three different base diameters.

25. Machinist-style three-jaw scroll chuck.

26. Small single-center screw chuck (often used for turning wine stopper caps).

27. Large pin chuck held inside a combination chuck. A predecessor of the modern scroll chuck, the combination chuck performed a number of chucking operations. In this case it’s holding a pin chuck—the shaft goes into a drilled hole with a small round rod inserted into its gap to lock the chuck in the hole.

28. Four-jaw scroll chuck with standard jaws.

29. Four-jaw scroll chuck with small spigot-type jaws.

30. Vacuum drum chuck with black gasket material.

31. Large jaws for reverse chucking. Equipped with rubber pads that can be adjusted to allow grasping or expanding into work of different diameters, these jaws mount on a four-jaw scroll chuck.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.