We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Loose Tenon Joinery

Rout 4 variations of these super-strong joints with a versatile shop made jig.

By Bill Hylton

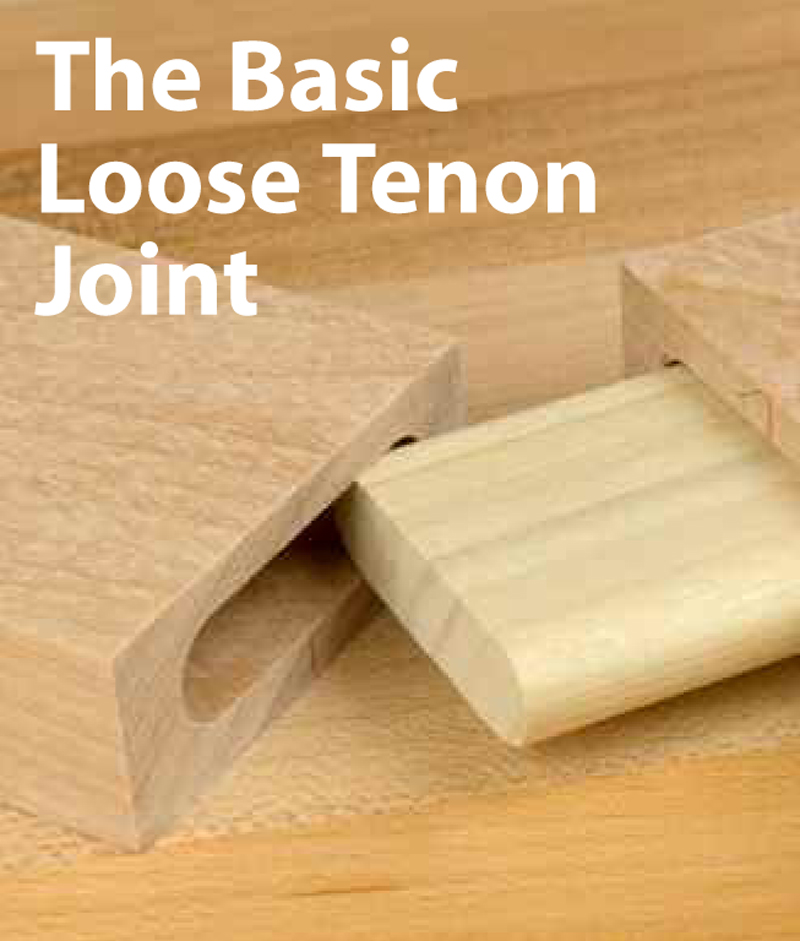

I’ve used a number of different methods to create mortise and tenon joints, but I keep coming back to loose tenons, because they’re easy, strong and versatile. Instead of cutting a tenon on one part and a mortise in the other, I rout identical mortises in both parts, and connect them with a fitted strip of wood—a loose tenon. Loose tenon joinery is perfect for casework, tables and doors of all sizes.

The only tools you need to start making loose tenon joints are a plunge router equipped with an edge guide, straight bits designed for plunge cutting and a mortising block—a shopmade jig I’ve designed that you can make in a day.The mortising block minimizes layout work and allows routing both edge and end mortises from the same router setup.

You can use off-the-shelf bits and just about any plunge router, but a precision edge guide is a must. I use the Micro-Fence edge guide, which I think is the best available (see Sources, below).

The mortising block

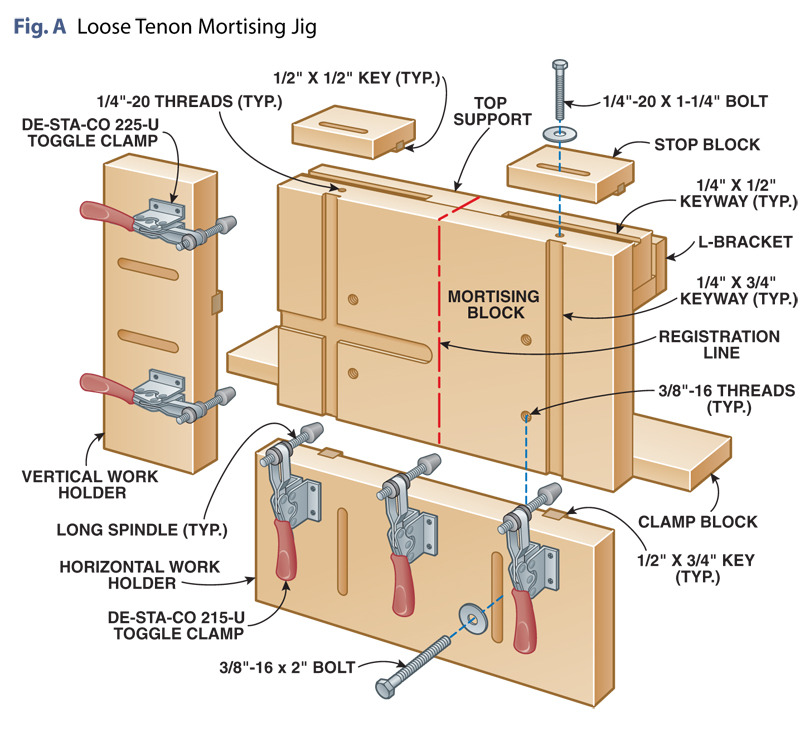

This jig holds the workpiece, supports the router and controls its movement (Fig. A, below).The jig consists of the mortising block itself, a top extension, an L-bracket and a clamp board for bench mounting.

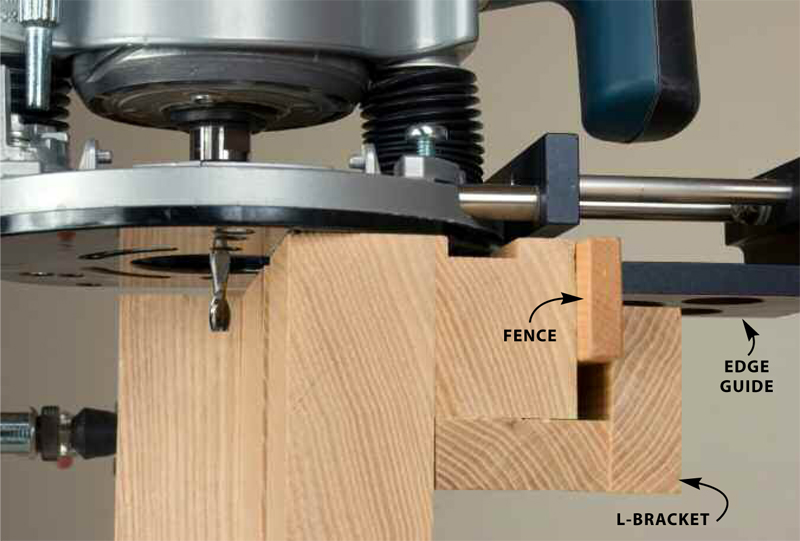

The face of the block has dadoes and mounting-bolt holes for the two work holders—horizontal for edge mortising and vertical for end mortising. The router sits on top of the block and overhangs the workpiece.The router’s edge guide is housed in a track formed by the L-bracket (Photo, opposite). Adjustable stop blocks set the mortise length.

How the jig works

• The jig’s registration line locates the workpiece.

• The jig’s L-bracket tracks the router and keeps the mortise aligned with the edges of the workpiece.

• The mortise’s width is determined by the bit’s diameter.To create mortises wider than the bit, you reposition the fence and make a second pass.

• The mortise’s depth is controlled by the router’s plunge mechanism.

• The mortise’s length is governed by the jig’s adjustable stop blocks.

• The mortise’s lateral (side-to-side) positioning is controlled by the router’s edge guide.

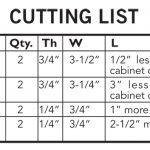

Build the jig

1.Mill stock for the main parts and cut the pieces to final dimensions (Fig. B, below).The mortise block’s body and the horizontal work holder must be exactly the same length, because you reference from the ends to rout the vertical keyways.

2. Rout 1/4″ deep vertical keyways in the mortising block and the horizontal work holder.

3. Rout single 1/4″ deep horizontal keyways in the mortising block and the vertical work holder.The block’s keyhole is stopped.

4. Rout mounting-bolt slots in each work holder, using a plunge router and an edge guide.

5. Plane 1/2″ thick stock to fit the work holder keyways. Cut pieces to length to create the keys. Attach them.

6. Clamp the horizontal work holder to the mortising block.Tap a 1/2″ brad point drill at both ends of each slot to transfer its location to the block. Remove the work holder and scribe vertical lines on the block through the four points you marked. Clamp on the vertical work holder, mark the slots and scribe a pair of horizontal lines.

7.Drill holes for the work holder mounting bolts at the four points where the horizontal and vertical lines intersect.To secure the 3/8″ bolts, I cut threads in the wood itself.To do this, drill the four holes with a 5/16″ bit and use a 3/8″-16 tpi tap to cut the threads (see Sources).No cutting fluid is needed; just turn the tap into the hole, then back it out. Alternatively, you can use Tnuts or drive threaded inserts into the body to secure the bolts.

8.Glue and clamp the top extension to the mortising block. Clean off any dried glue after removing the clamps. Then joint the assembly to ensure that its top surface is square to the face.

9. Attach a 3/8″ thick wood fence to your router’s edge guide.Then size the L-bracket parts to create a groove that will house the fence.The fit should be snug, so the fence slides without any wobble.Glue the L-bracket parts together and install them.

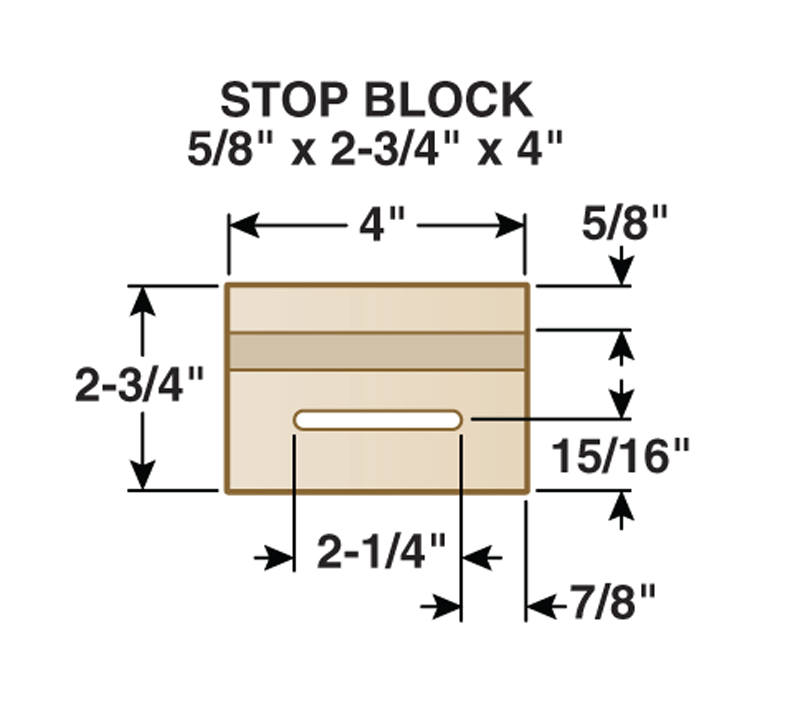

10.Make both stop blocks from one long piece of 5/8″ by 2-3/4″ stock. Rout the 1/4″ deep keyway and two mounting bolt slots. Cut the stops to final length.Make keys and attach them.

11. Rout matching keyways in the top of the mortising block.

12. Set the stops in place on the block and mark locations for mounting bolt holes.Drill and tap the holes for 1/4″-20 tpi bolts.

13. Install toggle clamps on the work holders (see Sources). I installed longer threaded spindles on all the clamps and used a 500-lb.size on the vertical work holder. Be sure to mount the clamps so they don’t interfere with the router.

14.Draw a registration line centered on the face and top of the mortising block.

15.Glue on the clamp block.

Create the basic loose tenon joint

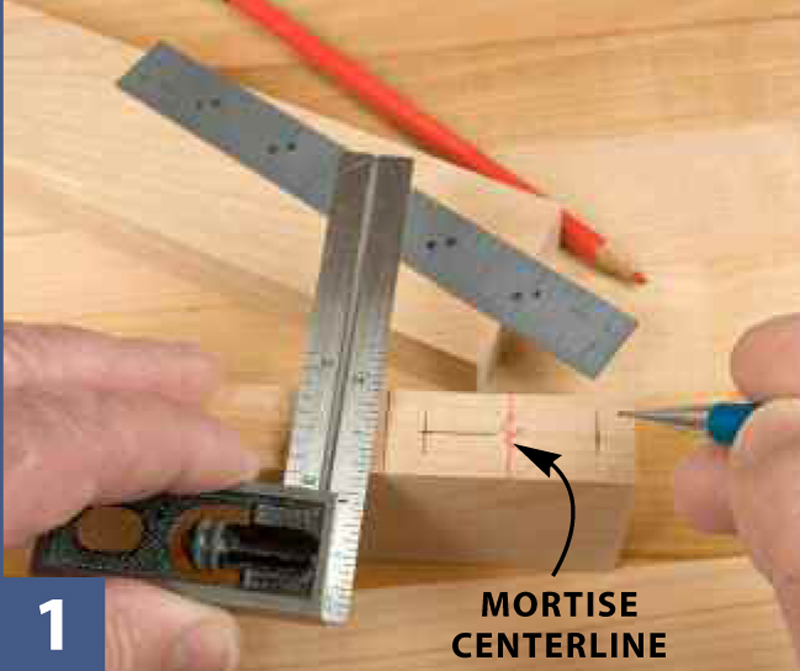

1. Lay out an edge mortise (Photo 1). It doesn’t have to be elaborate, just lines marking the mortise ends and centerline. Only one line is essential: a centerline across the mortise. This mark aligns with the jig’s registration line.

2.Position a test piece on the jig, using the horizontal work holder (Photo 2).

3.Adjust the work holder so the edge of the workpiece is flush with the jig’s top. Line up the workpiece centerline with the block’s registration line (Photo 3).Adjust the toggle clamps to hold the work securely.

4. Install a bit designed for mortising in the router.Up-spiral bits are popular these plunge cuts, but they’re not essential.

5. Install the router on the jig and test-slide the edge guide’s wood fence in the L-bracket groove. Apply wax, if necessary.

6. Bottom the bit onto the workpiece. Then move the router to center the bit on the mortise centerline (Photo 4). Lock down the edge guide and set the plunge depth.

7. Install the stop blocks to establish the length of the mortise (Photo 5).

8. Rout the mortise (Photo 6). That’s all it takes. As long as the faces of the workpieces are oriented the same way on the jig, all the edge mortises routed with this setup will be the same, regardless of where they fall on the workpiece. Just scribe a centerline across each mortise, and align it with the registration line on the block (Photo 7). If all of the mortises are located in the same place on each workpiece, you don’t even have to mark them. Instead, just fasten a stop on the jig against the end of your test piece and use it to register the workpieces.

9.The only change you have to make to rout the matching end mortises is to switch work holders (Photos 8 and 9).

10.Mill loose tenon stock to complete the joint. First, plane a length of stock to fit the mortises. It should slip in without wiggling or binding. Rip the blank to width, slightly less than the mortises’ length.Next, round the blank’s edges to match the mortises. Then cut individual loose tenons from the blank.

Reinforce a cope and stick joint

Routed cope and stick joints look great, but their stub tenon construction may not be suitable for large cabinet doors. Adding loose tenons strengthens these joints.

Rout the mortises before you rout the cope and stick profiles, so you don’t have to work around stub tenons on the ends of the rails. (The mortises won’t interfere when you rout the profiles.) Center the mortises across the thickness of the workpiece.They probably won’t align with the stub tenons produced by the cope cuts, but that doesn’t matter, because everything will be hidden in the assembled joint.

Start with the end mortises.Offset them away from the rails’ inner edges, so the panel groove won’t cut into the mortises (Photos 12, 13 and 14). Locate the edge mortises in the stiles according to the rails’ offset end mortises.

Be mindful of the rails’ offset mortises when you rout the profile and panel grooves. It’s all too easy to rout the wrong edge.

Twin mortise joints

In post-and-rail constructions made using thick stock, you can make stronger joints by doubling the loose tenons.The inside mortises on the posts of these corner joints will intersect, so they must be shorter; their tenons are mitered.The outside post mortises are deeper, so their tenons can be longer.The rail mortises can all be the same depth.

Orient the workpieces with their outside faces against the mortising block. Set up and rout the outside mortises.You’ll have to change work holders when you switch from routing edge to end mortises. Reposition the bit and rout the inside mortises (Photo 15). Reduce the final plunge depth when you rout these mortises in the posts.

Loose tenon table joint

In this construction, the apron usually is inset from the leg faces.My approach is to set up for the mortises in the legs (Photos 16 and 17).To rout the aprons, I use double-faced tape to install a shim equal in thickness to the inset between the apron and the block (Photo 18).Be sure to install the aprons outside-face-in before routing their mortises.

Sources

(Note: Product availability and costs are subject to change since original publication date.)

Micro Fence, microfence.com, 800-480-6427, Micro Fence Edge Guide.

Buy Destaco, buydestaco.com, 800-560-9292, De-Sta-Co Horizontal Toggle Clamps, #215U; #225U (500 lb. cap.).

Tap and Die sets are available at hardware stores and home centers.

Fig. A: Loose Tenon Mortising Jig

Despite their name, loose tenon joints fit as precisely as traditional mortise and tenon joints, and are just as strong.

Fig. B: Dimensions

Mortising Block

Stop Block

Horizontal Work Holder

Vertical Work Holder

Adapt your router to the jig by installing a fence on the edge guide that fits the slot formed by the jig’s L-bracket.This keeps the bit aligned as the router slides back and forth. To move the bit laterally, you simply adjust the edge guide.

The Basic Loose Tenon Joint

1. Lay out one edge mortise on a test piece to set up the router and jig.The mortise centerline is used for positioning the workpiece on the mortising block—it’s the only layout mark required for every mortise.

2. Set up the jig to rout the edge mortises. Install the horizontal work holder and position the test workpiece so its edge is flush with the top of the jig.Then tighten the bolts.

3. Align the work’s mortise centerline with the jig’s registration line.Then lock the test piece in position.

4. Install the router and adjust the edge guide to center the bit on the work.Then adjust the router’s plunge-depth stop to the desired mortise depth.

5. Install the stop blocks. Move the router to one end of the mortise and align the bit’s edge with the layout mark. Slide the stop against the router and tighten the bolt. Set the second stop the same way.

6. Rout the mortise with a series of shallow cuts. Plunge the bit about 1/8″, feed quickly to the far stop, retract the bit, return to the starting position and go again.

7. Mark your stocks’ outside faces and always orient the same face against the mortising block when you rout. Once all the edge mortises are routed, switch to the vertical work holder to rout the end mortises.

8. To mount the vertical holder, clamp a workpiece with its mortise centerline aligned with the jig’s registration line. Slide the holder against the workpiece and tighten the bolts.

9. Install the router and rout the end mortise. The length, width, depth and placement of the mortise don’t change when you switch work holders.

10. Size a loose tenon blank. Plane a length of stock to fit the mortises. It should slip in without wiggling or binding. Rip the blank to width, slightly less than the mortises’ length.

11. Round the tenon blank’s edges to match the mortises.Then use a crosscut sled to cut individual loose tenons from the blank.

Reinforce a Cope and Stick Joint

12. This variation requires offsetting the rail mortises, so they don’t interfere with the panel groove. Lay out the offset mortise on a pre-routed rail.Then use this rail to position the vertical work holder.

13. Rout the mortises before you rout the cope and stick profiles.Your initial set-up positions the mortise in only one end of each rail, because both ends of the rail must be routed with the same face against the block.

14. To position the mortise in the other end, install a shim equal to the panel groove’s depth between the work stop and the rail.

Twin Mortise Joints

15. Rout twin mortises in two steps. Lay out and rout the first mortises in both the edges and ends. Reposition the bit for the second mortises and go again. Always orient the same face against the fence.

Table Joint

16. With table joints, the aprons are usually inset from the legs.Start by mortising the legs. Clamp the leg with its outside faces against the block and the work-holder.Position the bit, set the stops and rout the mortise.

17. Flip and rotate the leg to rout the second mortise. It doesn’t matter that the leg now extends in the opposite direction, because the mortises are centered on the jig’s registration line.

18. To inset the aprons from the legs, you offset their mortises by the amount of the inset. Attaching a shim of the desired thickness to the jig automatically offsets the mortise correctly.

This story originally appeared in American Woodworker April/May 2009, issue #141.  Purchase this back issue.

Purchase this back issue.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.