We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Heavy-Duty Folding Shop Table

You can build this

workhorse in a day,

using little more than

a tablesaw, jigsaw,

hacksaw and a drill.

By Tom Caspar

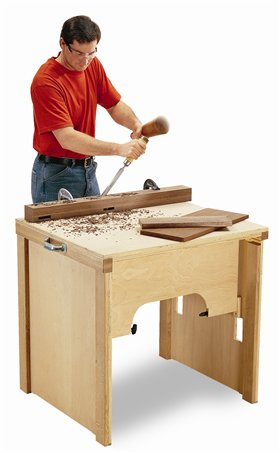

1. This worktable is built for

strength. It won’t wobble, sag

or walk across the floor. Weighing 70

pounds or so, it’s not going anywhere

until you stow it away. |

|

Click any image to see a larger version.

|

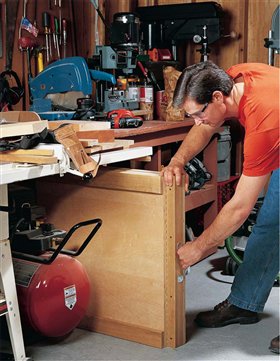

2. This table is built like a rock but knocks down in only a minute. You don’t

need any tools and you don’t have to keep track of any loose pieces. Simply unscrew

four knobs, fold the rails and legs on top of each other and tuck the worktable away. |

|

|

3. Cut one long groove in each rail to receive the four

pieces of threaded rod that hold the table together. Use

a tall fence and a featherboard to steady the workpiece.Then,

cut out an arch in the rail so your hands have room to turn the

knobs on the threaded rods. |

|

|

4. Mount the hinges before assembling the table.

Positioning the hinges is critically important, but easy to

do. Simply fold a hinge over one of the hardwood riser blocks

and clamp it in place. Drill pilot holes with a self-centering bit.

Drive in the screws, unfold the hinge and you’re good to go. |

|

|

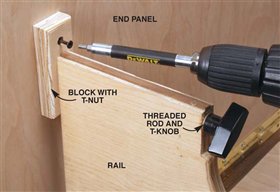

5. Lock the table together with bolts and T-nuts. The T-nuts

are buried in wood blocks that are screwed to the table’s end

panels. Locating the blocks in exactly the right spot is easy.

Step 1. Thread the blocks onto the threaded rod buried in the rail.

Step 2. Swing the rail upright.Then drive a screw through the T-nut

block and into the end panel.

Step 3. Unthread the bolt from the T-nut block. Fold the rail down and

out of the way.Then drive in the bottom screw through the T-nut block.

This story originally appeared in American Woodworker April 2002, Issue #93.

|

|

|

Product Recommendations

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.