|

Why make an ordinary

table when

you can make this elegant

one instead? The difference

is in the details.

That’s the genius behind

the furniture of Charles

and Henry Greene, California

architects and furniture

designers active during

the first quarter of the

20th century. Through

thoughtfully designed

details, they combined the

flowing, organic curves

found in traditional Chinese

furniture with the

hard-edged lines and pronounced

joints of the popular

Arts and Crafts style.

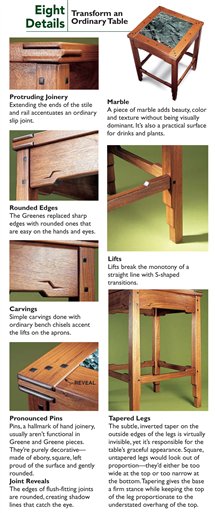

8 Details: Transform an ordinary table

Although this table isn’t a replica of a specific Greene

and Greene piece, it incorporates many of the details

they used—accentuated joinery, decorative pins, lifts

and rounded edges. It’s made from walnut, one of several

woods they favored. You’ll need at least 10 lineal feet of 2-in.

square stock for the legs. It’s easiest to use 5/4

stock for all the other pieces—10 bd. ft.will be plenty.As on original Greene and Greene pieces,

the pins are ebony. (see Sources, below).

The marble inset in the top is a 12-in.-square floor

tile. Marble tiles are available at flooring stores. Have the marble in hand before

you cut any of your lumber. Tiles can vary as much as

1/4-in. from the specified dimensions. You’ll have to

change the lengths of the stiles and rails for the top and

the aprons and stretchers for the bottom if your tile is

not exactly 12 in. by 12 in.

Make the top

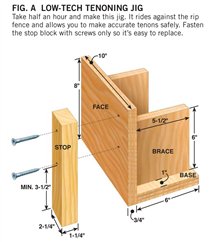

It’s easy to make the protruding ends that accentuate the

top’s joinery. Just make the tenons longer and the slots

deeper than the widths of the stiles and rails (see Photos

1 and 2, and Fig. B, Detail 1). Assemble the top

pieces and mark the inside edges (they receive a smaller

roundover). Then test the fit of the marble. The plan

measurements allow 1/16-in. clearance for it. If you

want a tighter fit, remove a bit more from the tenon

shoulders and make the slots a bit deeper.

Mortise holes for the ebony pins in the top stiles

and rails.You’ll need only two fence settings to cut all of

these holes (Photo 3 and Fig.B,Detail 2).Next, round

over the ends of the rail tenons and the stile legs with a

3/16-in. radius bit (Photo 4).Use the same bit to round

the outside edges of the stiles and rails, top and bottom

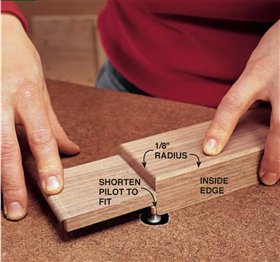

(Fig.B, Detail 1). Create joint reveals between the stiles

and rails by routing the rail shoulders and all top and

bottom inside edges with a shortened 1/8-in. radius

round-over bit (Photo 5).Then glue the top together.

Make ebony pin blanks (Photo 6). Seat them with a

hammer and a bit of glue, saw them off (Photo 7) and

round their tops (Photo 8).

Make the legs

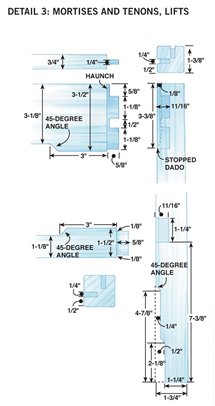

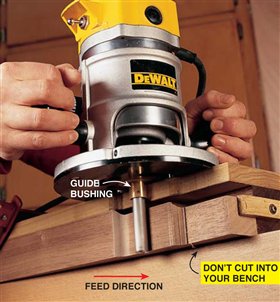

Rout lifts at the bottom of adjacent inner sides of the leg

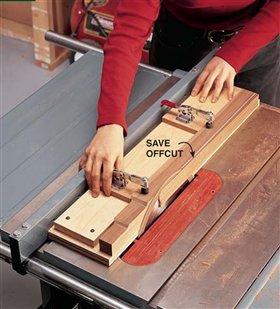

blanks (Photo 9 and Fig.B,Detail 3).Then taper the two

outer sides (Photo 10 and Fig.B, Detail 2).

Cut mortises for the haunched apron tenons on the

two inner sides of each leg (the sides with lifts). First,

using the tablesaw, cut stopped dadoes. They provide

room for the haunch of the tenon and guide the bit

when cutting the mortises (Photo 11).

These dadoes are parallel to the tapered side of

the leg so the apron has a consistent reveal. The

mortises for the stretchers are also parallel to the outside

tapers, and have the same reveal as the aprons.

Mortise holes for the ebony pins (Fig.B, Detail 2).

This time, position the legs with their straight inner

sides against the fence.Level the faces using a tapered

offcut, and protect the mortise cheeks with sacrificial

plugs before cutting.Round the edges of the legs with

the 3/16-in. radius bit. You’ll have to round the inside

edges,where the lifts meet, by hand.

Make the aprons

and stretchers

Prepare four blanks with tenons on both ends.Rout

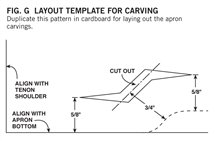

the lifts using a template (Photo 12).Add the carvings

to the aprons (Photo 13 and Fig. G).Round the

bottom edges of the aprons and the top and bottom

edges of the stretchers.

Assembly

Glue together two sides, each with two legs, an

apron and a stretcher and install the ebony pins.

Complete the glue-up, adding the remaining two

aprons and stretchers. Then install the rest of the

pins.Glue blocks on the insides of the aprons for the

screws that hold the top.

Install the ledger strips for the marble, working

from the underside of the top (Photo 14). Set the

marble in place after the finish has cured (Photo 15).

I used a glaze of burnt sienna and burnt umber

over a seal coat of shellac, topcoated with varnish.

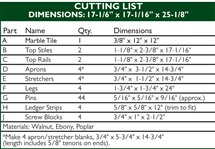

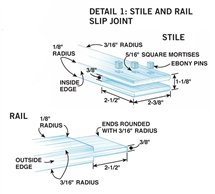

Cutting List

Fig. A: Low-Tech Tenoning Jig

Fig. B: Exploded View

Detail 1: Stile and Rail Slip Joint

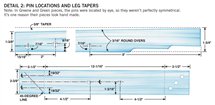

Detail 2: Pin Locations and Leg Tapers

Detail 3: Mortises and Tenons, Lifts

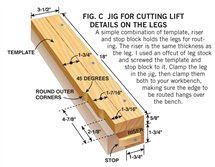

Fig. C: Jig for Cutting Lift Details On the Legs

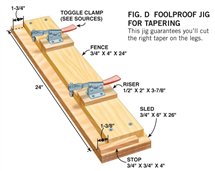

Fig. D: Foolproof Jig for Tapering

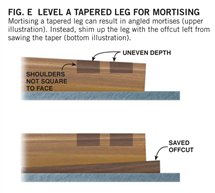

Fig. E: Level a Tapered Leg for Mortising

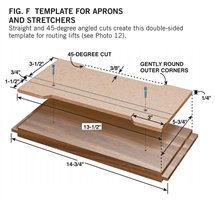

Fig. F: Template for Aprons and Stretchers

Fig. G: Layout Template for Carving

Sources

(Note: Product availability and costs are subject to change since original publication date.)

All RIghteous Woods, righteouswoods.net, 877-843-

9265, Ebony

4/4 Madagascar ebony. You’ll need less than 1 bd. ft.

Seven Corners Hardware, 7corners.com, 800-328-0457,

3/16" radius HSS router bit w/

pilot, Bosch.

Eagle America, eagle-america.com, 800-872-2511, 2-1/2"-long straight bit,

1/2" shank, #102-0975;

1/8-in. radius bit with pilot, 1/4"

shank, #159-0202.

Woodcraft, woodcraft.com, 800-225-1153, 5/8" O.D. brass template guide

bushing, #147934; Brass lock nut for bushing, #1

MCLS, mlcswoodworking.com, 800-533-9298, Toggle clamps, #9058.

This story originally appeared in American Woodworker August 2000, issue #81.

|

|

Click any image to view a larger version.

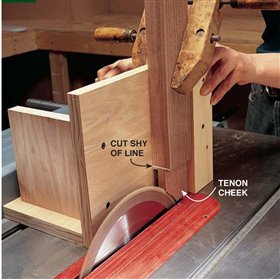

1. Saw tenon cheeks on the rails using a shop-made

tenoning jig (Fig. A). Remove the waste with bandsaw cuts first.

Then you can raise the tablesaw blade and clean the tenon

cheek in one pass. Cut the slot mortises in the stiles with the

same jig. CAUTION: This operation is difficult to do with the guard in

place. Use extra care.

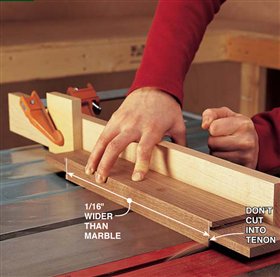

2. Square the tenon shoulders using a miter gauge with a

stop block.The critical dimension on the rails is end-to-end

between the shoulders. On the stiles it’s the distance between

the slots.These dimensions must be slightly longer than the

marble so it fits in place after the top is assembled. CAUTION:This

operation is difficult to do with the guard in place. Use extra care.

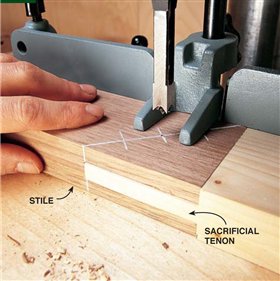

3. Cut square holes for the pins with a 5/16-in. mortising

chisel and bit. Space the pins evenly on a diagonal that starts at

the end of the slot mortise. Mortise through the upper leg of

the stile. Stop in the sacrificial tenon. It keeps the chisel and bit

from blowing out the inside surface of the joint.

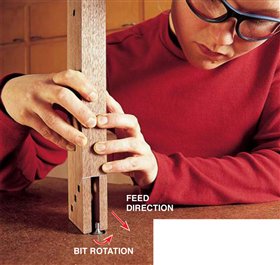

4. Hold the styles and rails upright to round the

ends.To reduce the risk of

blowout, always cut into the

rotation of the bit. Clamp a

piece of hardboard with a 1-in.

hole on top of your router

table to support these short

pieces while routing.

4 (continued). To fit inside the slot between

the legs of the stile you’ll

need a bit with a 1/4-in. pilot

(see Sources, below).

5. Round the rail shoulders with a 1/8-in. radius bit.

Shorten the bit slightly, by grinding the tip of the pilot, so it fits

under the tenon.The inside edges of the stiles and rails also

receive an 1/8-in. rounding.

When the top is assembled, these rounded edges create

reveals at the joint between the stiles and rails and between

the wood and the marble.

6. Saw square stock for the ebony pins from a single

saw set-up. First, cut a kerf in the face side of the board.Then,

with the board on its edge and the kerfed face against the

fence, make a second pass. A featherboard and push stick are

mandatory when cutting small parts.This shop-made push stick

includes a stop that prevents the newly cut square blank from

kicking back. CAUTION:This operation is difficult to do with the

guard in place. Use extra care.

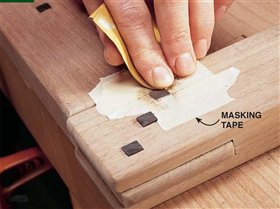

7. Saw the pins proud of the surface, after seating them

in the glued-up top. Use a notched credit card as a spacer so all

the pins are a consistent height.

8. Sand the pins by hand, leaving them rounded and slightly

proud of the surface. Bear down with your fingertip on each

side of the pin to cut down the edges and create the rounded

shape.Tape protects the walnut from scratches.

9. Rout the leg lifts using a jig (Fig. C) with a template

and a router (outfitted with a 5/8-in.O.D. guide bushing and

a 2-1/2-in. long, 1/2-in. dia. straight bit).To make routing

easier, saw away most of the waste first.When you use this

guide bushing and bit, the finished edge of the leg will be

1/16-in. away from the edge of the template, so be careful

not to saw away too much.

10. Cut leg tapers with this shop-made jig (Fig. D). It holds

the legs securely and keeps your fingers away from the

blade. Save the tapered offcut. It’ll be used for mortising.

CAUTION:This operation is difficult to do with the guard in

place. Use extra care.

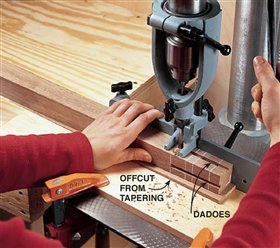

11. Cut mortises in the straight, untapered sides of the legs,

using stopped dadoes to set and guide the bit. Make sure the

leg’s two tapered sides are against the base and the fence.You’ll

have to level the leg so the mortise is perpendicular (Fig. E).

Use the scrap left from sawing the tapers for leveling, making

sure it completely supports the leg. Cut the mortises for the

stretchers the same way.

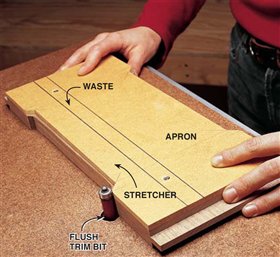

12. Rout two lifts at once using a template (Fig. F) and a

blank wide enough to contain both an apron and a stretcher.

Saw away most of the wood to be removed on the bandsaw

before routing. After routing, saw the blank into a separate

apron and stretcher.

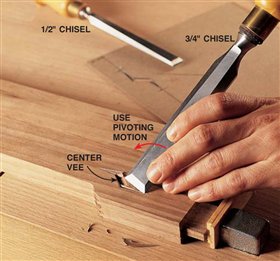

13. Carve the apron detail by making vee-cuts with two

chisels. Cut the center vee first, about 1/4-in. deep, with a

1/2-in. chisel.Then use a 3/4-in. chisel for the tail vees. Use a

pivoting motion from the outer end of each vee so they start

at nothing and deepen towards the center. After the vees are

carved, soften their sharp shoulders with the chisel.Then

smooth everything gently with fine sandpaper.

14. Fasten the ledger strips that hold the marble. It’s easy if

you flip the top upside-down. For the marble and top to be

flush, clamp the top to two flat sticks and lay the marble in

place on top of them. Put a bead of glue on one edge of the

ledger strips and nail away.

15. Set the marble top in place with a bead of silicone caulk

on the ledger strips.

|